3-4 Troubleshooting Cardiac Stress Treadmills Service Manual

*The type and the rate of bearing noise can help determine which bearing

is at fault. The number of knocks per minute varies with treadmill speed

because the roller speeds change as the belt speed changes.

**Use a mechanical stethoscope or a piece of hose about two feet long, to

isolate bearing problems. Hold one end of the hose near the suspected

bearing and the other end near your ear. Compare several bearings to

determine which is the faulty one.

Error Flow Charts

Use the flow charts on the following pages for step-by-step

troubleshooting.

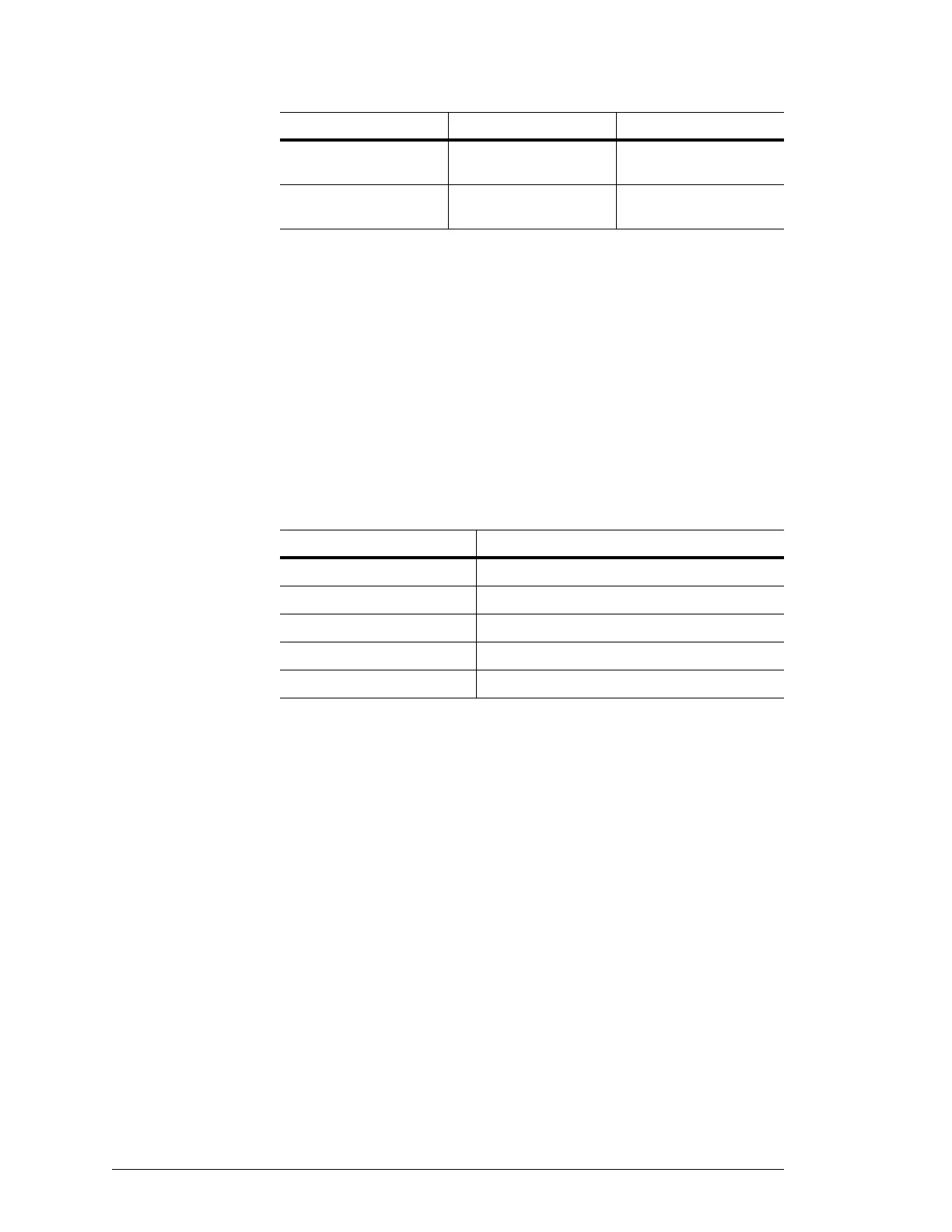

Squealing (similar to loose

automobile fan belt).

Drive belt loose. Adjust belt tension.

Replace belt if necessary.

Popping during grade

change.

Faulty elevation chain

alignment.

Adjust alignment of

sprockets.

Noise Possible Cause Action

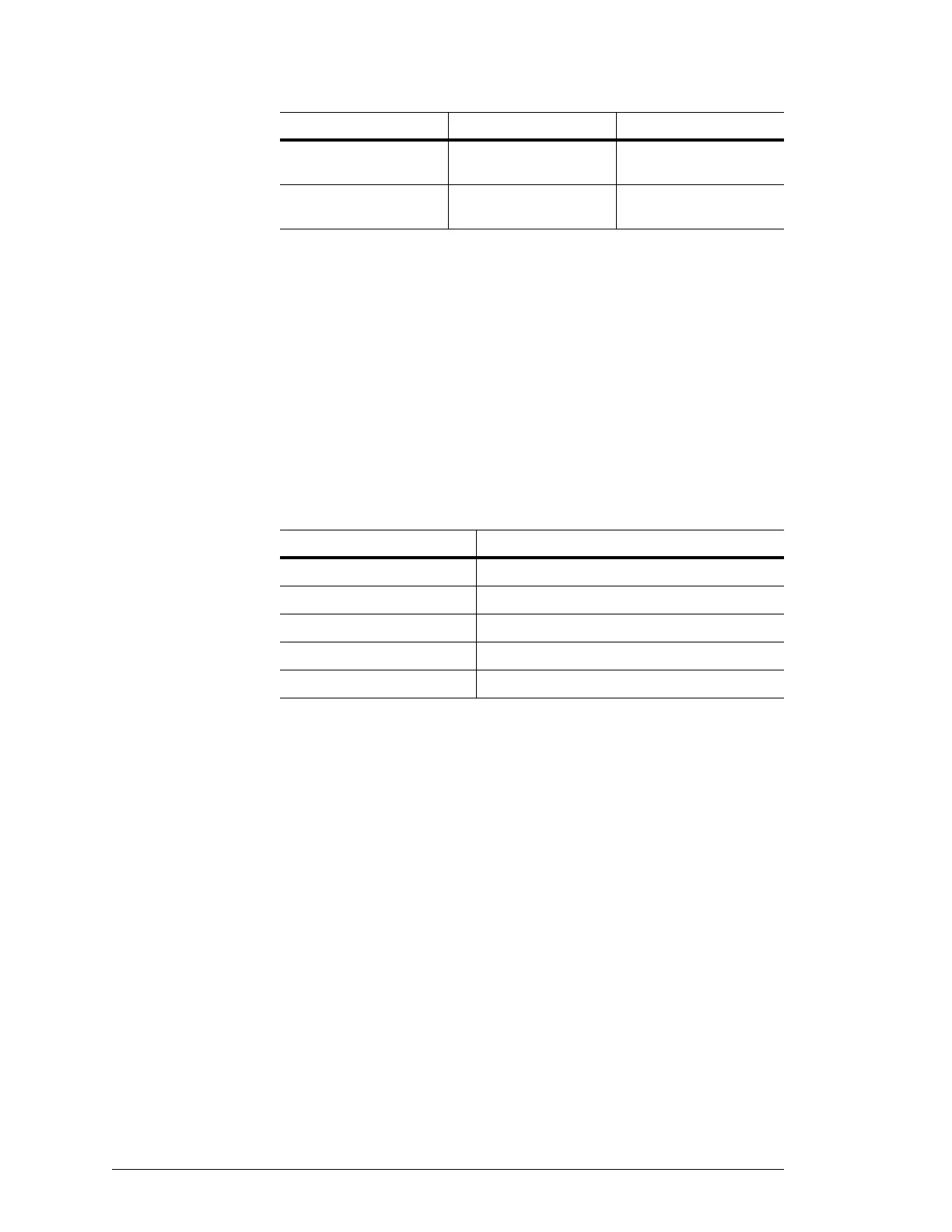

Error Code Flow Chart Page

EPHI and EPLO “Bus Voltage Flow Chart” on page 3-5

E201 “Grade Error Flow Chart” on page 3-6

E203 (Drive Motor) “Drive Motor Flow Chart” on page 3-7

E204 “Communications Link Flow Chart” on page 3-8

Grade Problems “Grade Problems Flow Chart” on page 3-9

Loading...

Loading...