GB-F-NL-58

GB

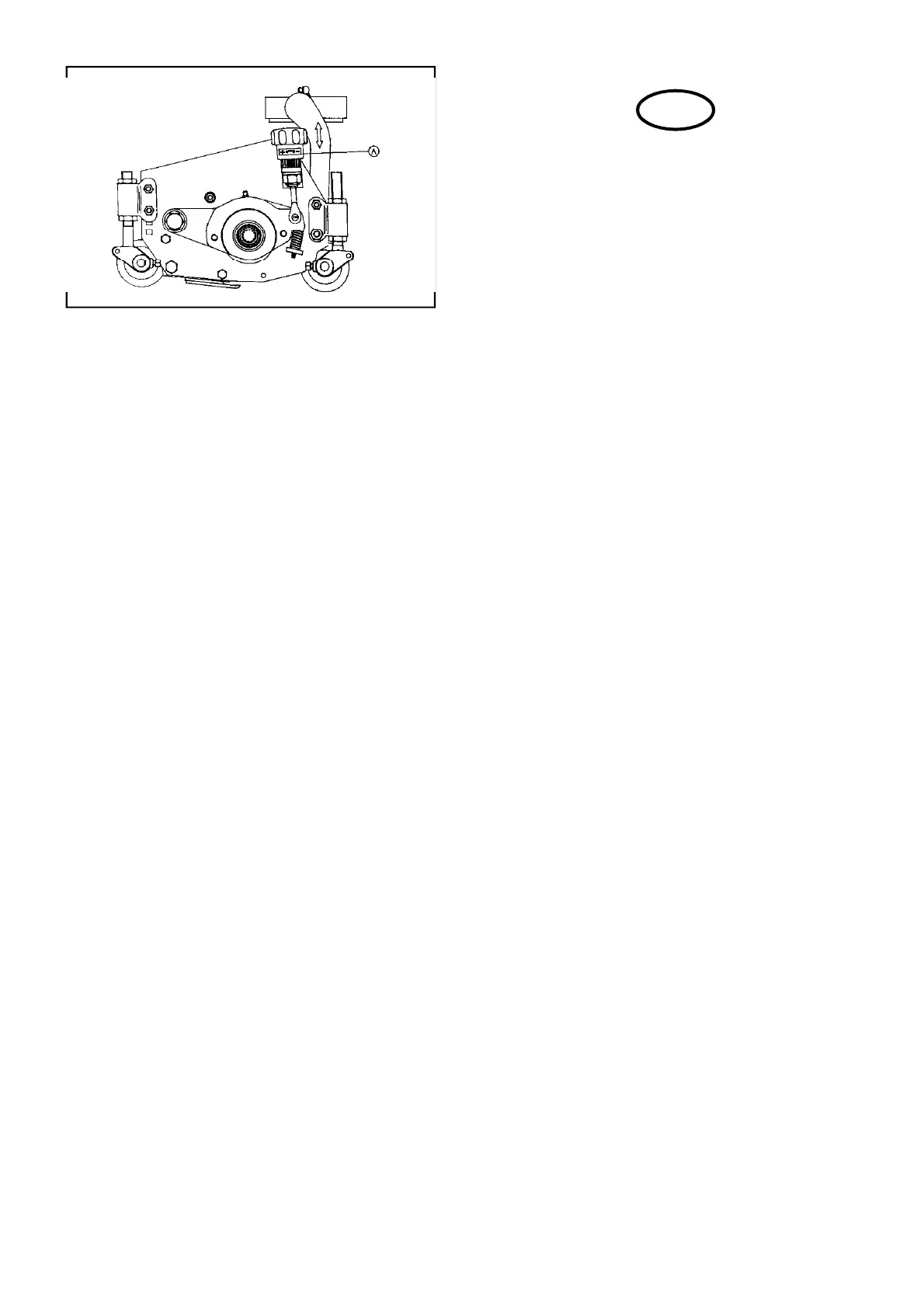

CUTTING CYLINDER TO BOTTOM BLADE

ADJUSTMENT (FIG.47)

To check that the cutting cylinder is set to the bottom

blade correctly, hold a piece of thin paper between the

edge of the blade and the spiral cutters and turn the

cylinder manually.

The paper should be cut cleanly along the total length

of the bottom blade, if not, some adjustment may be

necessary, BUT DO NOT OVERTIGHTEN.

Alternatively if the cylinder is worn it may require back

lapping before adjusting, see page 60.

To adjust:

1. To adjust the cylinder to the bottom blade lift and

turn alternately left and right hand handwheels (A

Fig.47). (clockwise to put on cut anticlockwise to take

off cut) and release, keep turning the handwheel until

it locates in the serrated locking ring. The adjuster is

of the notched type and each notch is moving the

cylinder in increments of approximately 0.04mm

(0.0015in).

THIS IS A SELF LOCKING MECHANISM THERE

BEING NO NECESSITY TO UNLOCK OR LOCK

THE MECHANISM.

IMPORTANT: IN ROUGH GROUND CONDITIONS

IT MAY BE NECESSARY TO LOCK THE NUTS

SECURING THE BEARING HOUSINGS TO THE

SIDE FRAME WHERE THEY RUN IN ADJUSTING

SLOTS TO RETAIN CYLINDER TO BOTTOM

BLADE SETTINGS. EXPERIENCE WILL DICTATE

THIS. THE NUTS SHOULD NORMALLY BE

TIGHTENED FULLY AND THEN BACKED OFF 1/2 A

TURN TO ALLOW HANDWHEEL ADJUSTMENT

WITHOUT THE NEED TO UNLOCK THE NUTS

FIRST.

CUTTING CYLINDER BEARINGS

The cutting cylinder bearings are self adjusting taper

roller bearings and require no adjustments.

FRONT AND REAR ROLL BEARINGS

The roll bearings are self adjusting taper roller

bearings and require no adjustment

Fig.47

Loading...

Loading...