GB-F-NL-64

GB

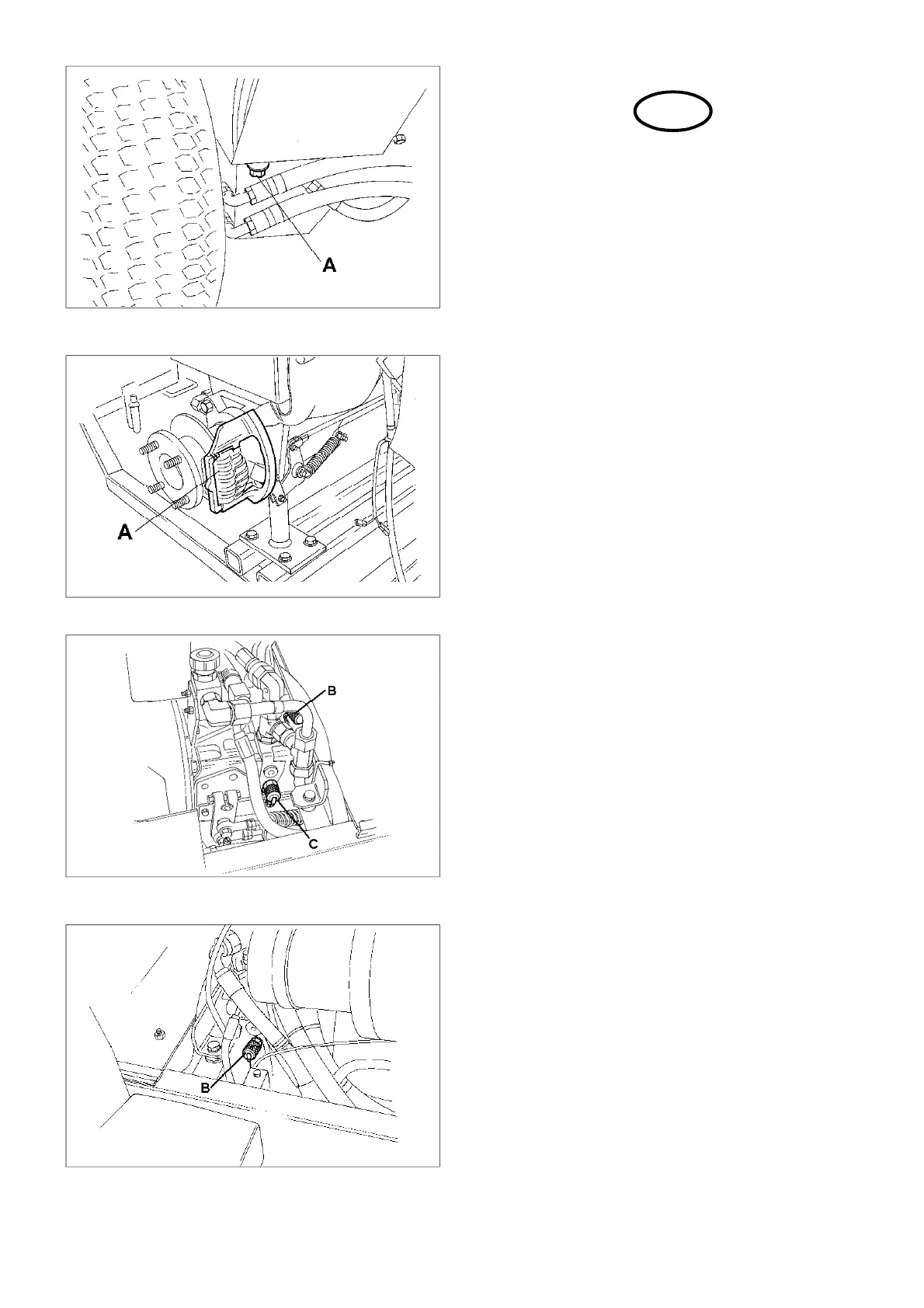

Fig.53

END OF SEASON

SERVICING

MACHINE

The machine should be thoroughly cleaned down to

remove all accumulations of grass clippings and

debris.

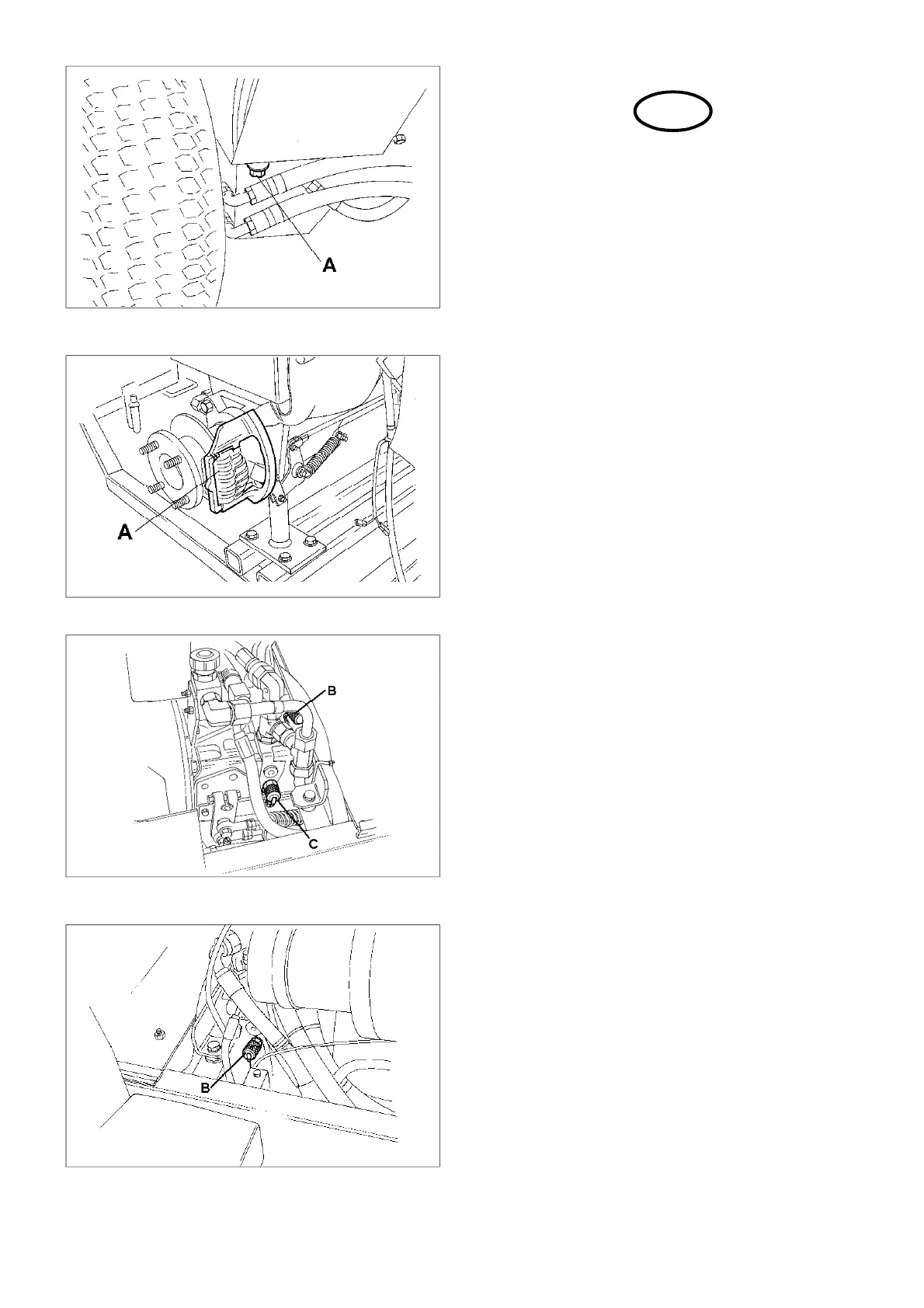

HYDRAULIC TANK (Fig.50)

Drain oil from hydraulic tank by removing drain plug

(A). Clean plug and replace. Replace hydraulic oil filter

canister (see below) and refill tank with Shell Tellus 46

hydraulic oil to correct level. Capacity approximately 27

litres (6 Imp.gals) (7.2 US gals)

NOTE: Absolute cleanliness must be observed when

filling the hydraulic tank.

HYDRAULIC OIL FILTER

The filter canister should be removed and discarded.

Replace with a new one before refilling hydraulic tank.

Run the machine and recheck level of oil in the tank.

Top up if necessary with Shell Tellus 46.

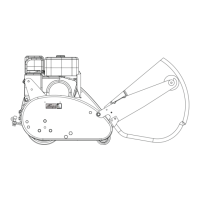

BRAKES (Fig.51)

After placing axle on stand, remove wheels brake

calipers.

Clean brake calipers and inspect hydraulic motor for oil

leaks. Inspect brake pads for wear, replace if

necessary.

HYDRAULIC SYSTEM PRESSURE GAUGE TEST

PORTS

If any problems are experienced with the hydraulic

system, service ports are provided to enable pressures

to be checked.

These service ports are situated below the seat on the

traction pump

TEST PORTS (Fig.52 & 53)

1. Transmission pressure forward 210 bar (3045psi)

(C Fig.52):

2. Transmission pressure reverse 210 bar (3045psi)

(B Fig.53):

3. Charge pressure 14 bar (200psi) (B Fig.52):

NOTE: Any servicing of the hydraulic system must be

carried out by trained service personnel

Fig.50

Fig.51

Fig.52

Loading...

Loading...