4” Standard Pump Installation, Operation & Service Manual Installing a Replacement Extractable Pump

38

12. Remove cover from wiring compartment.

13. Pull pigtail wires into wiring compartment.

14. Cut pigtail wires leaving approximately 8 inches (200 mm) hanging out of wiring compartment.

15. Strip insulation off all wires 3/8 inch (10 mm).

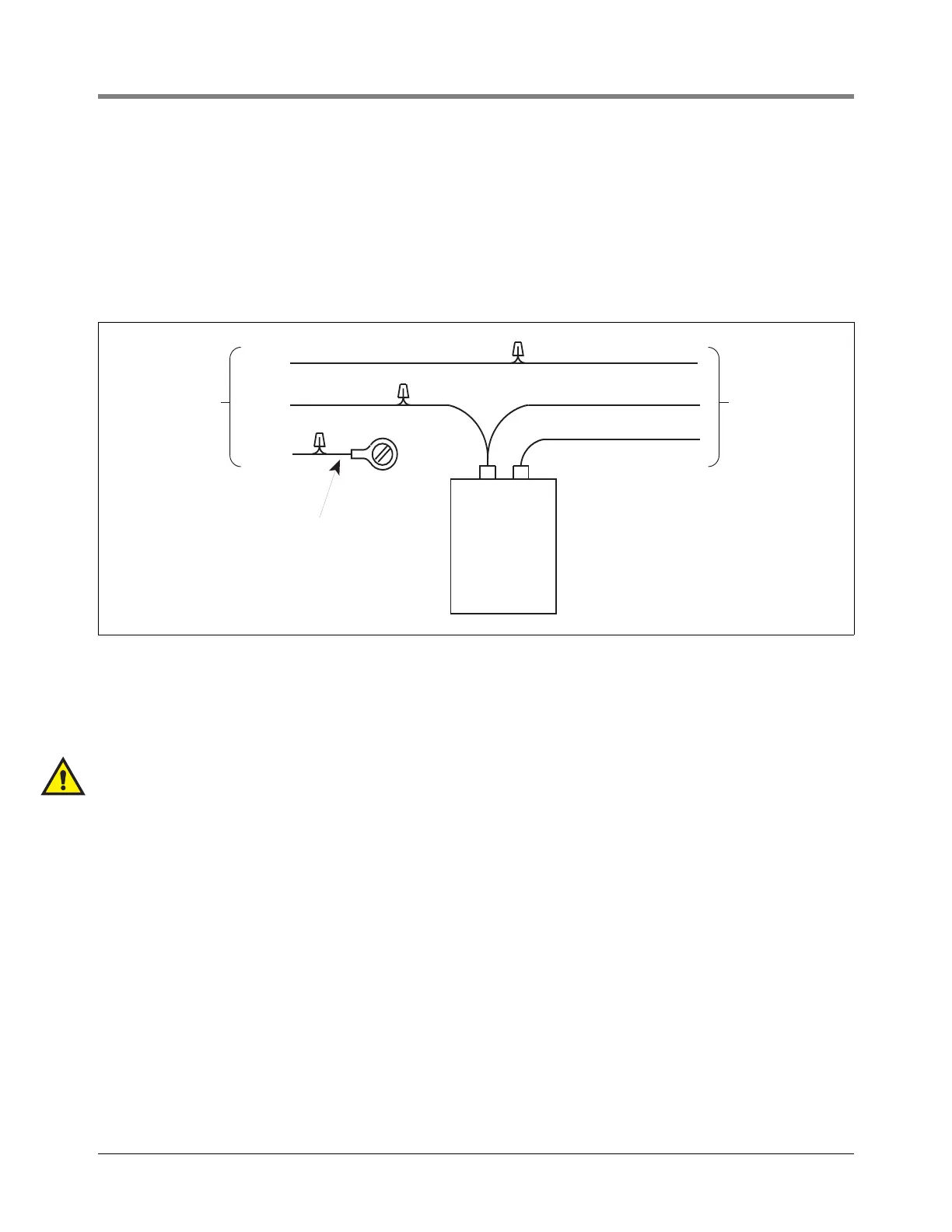

16. Using supplied wire nuts attach like colored pump pigtail wires to like colored electrical connector wires as

shown in Figure 33.

Figure 33. Wiring schematic

17. Install excess wire into wiring compartment. Replace wiring compartment cover. Torque to 35 ft-lb (50 N•m).

Thread sealant should not be used.

18. Install the pump into the manifold.

WARNING! For fixed length pumps:

If removed, install eyebolt plug, using an adequate amount of fresh, UL classified for petroleum, non-setting

thread sealant and torque to 50 ft-lbs (70 N•m). Confirm that the lifting eyebolt is properly torqued to 10 ft-

lbs (13.6 N•m) with a minimum of 6 full threads installed. Occasionally, eyebolts are removed after pump

installation and corrosion may occur in the threaded areas of the wiring compartment cover (eyebolt plug)

and the eyebolt. If corrosion has occurred, the cover and eyebolt should be replaced.

Utilize the lifting eyebolt to suspend the pump vertically and then install the pump into the manibold.

NOTE: Before replacing the extractable, make sure that the surfaces of the packer o-ring and the discharge

o-ring seals are clean.

19. Align the positioning dowels of the manifold with the holes in the packer.

20. Push the packer as far as possible against the manifold.

21. Insert the lock-down bolts and torque to 45 - 55 ft-lb (61 - 75 N•m).

22. Loosen the bolts that hold the conduit box to the manifold. Do not remove.

23. Swing the electrical connector into position.

24. Torque the electrical connector bolt to 25 - 50 ft-lb (34 - 68 N•m).

CAPACITOR

ORANGE

BLACK

RED

From power

panel

From female

connector

rj\153\fig13.eps

M1

M2

GND

Ground wire connection

in contractor's box

Loading...

Loading...