MODULE #9 - SERVICE OPERATIONS

The indicator has been fully calibrated at the factory and will only require a

scaling operation (Pro1or2)to display the units of the process. If the unit

appears to be indicating incorrectly or inaccurately, refer to the

troubleshooting section before attempting this procedure.

When re-calibration is required (generally every 2 years), this procedure

should only be performed by qualified technicians using appropriate

equipment. Signal source accuracies of 0.01% or better are required.

The procedure consists of applying accurate signal levels to the indicator

in a series of three steps. Allow a 30 minute warm-up period before starting

this procedure.

Note: Once the access Code 48 has been entered, there is no exiting this

program module without completing the calibration procedure.

ENTER ACCESS CODE

A code number (48) must be keyed-in prior to the calibration sequence to

guard against inadvertent entries. Access code numbers other then those listed

in this section, should not be entered at this step. If any are entered, undefined

or unpredictable operation could result.

“CodE” < > “0” to “99”

If the code number for the previous step was not recognized, the indicator

returns to “Pro 0”, with no action taken. Otherwise, the calibration

procedure is started.

SELECT SCALE REQUIRED

Place the factory supplied jumper in one of the four positions to select an input

range. (Refer to “Selecting The Input Range” section for more information.)

ENTER (-)100% OF PROCESS

Apply (-) full scale of the range which was selected. Allow the signal to

stabilize for 20 seconds before pressing “P”.

“StEP 1” (Press “P”)

ENTER ZERO REFERENCE

Apply 0 volts by shorting the inputs together.

“StEP 2” (Press “P”)

ENTER (+)100% OF PROCESS

Apply (+) full scale of the range which was selected. Allow the signal to

stabilize for 20 seconds before pressing “P”.

“StEP 3” (Press “P”)

Indicator calibration is complete. It is recommended that calibration be

checked by entering “Pro 1” and checking the displayed input values with the

signal source at different applied input levels.

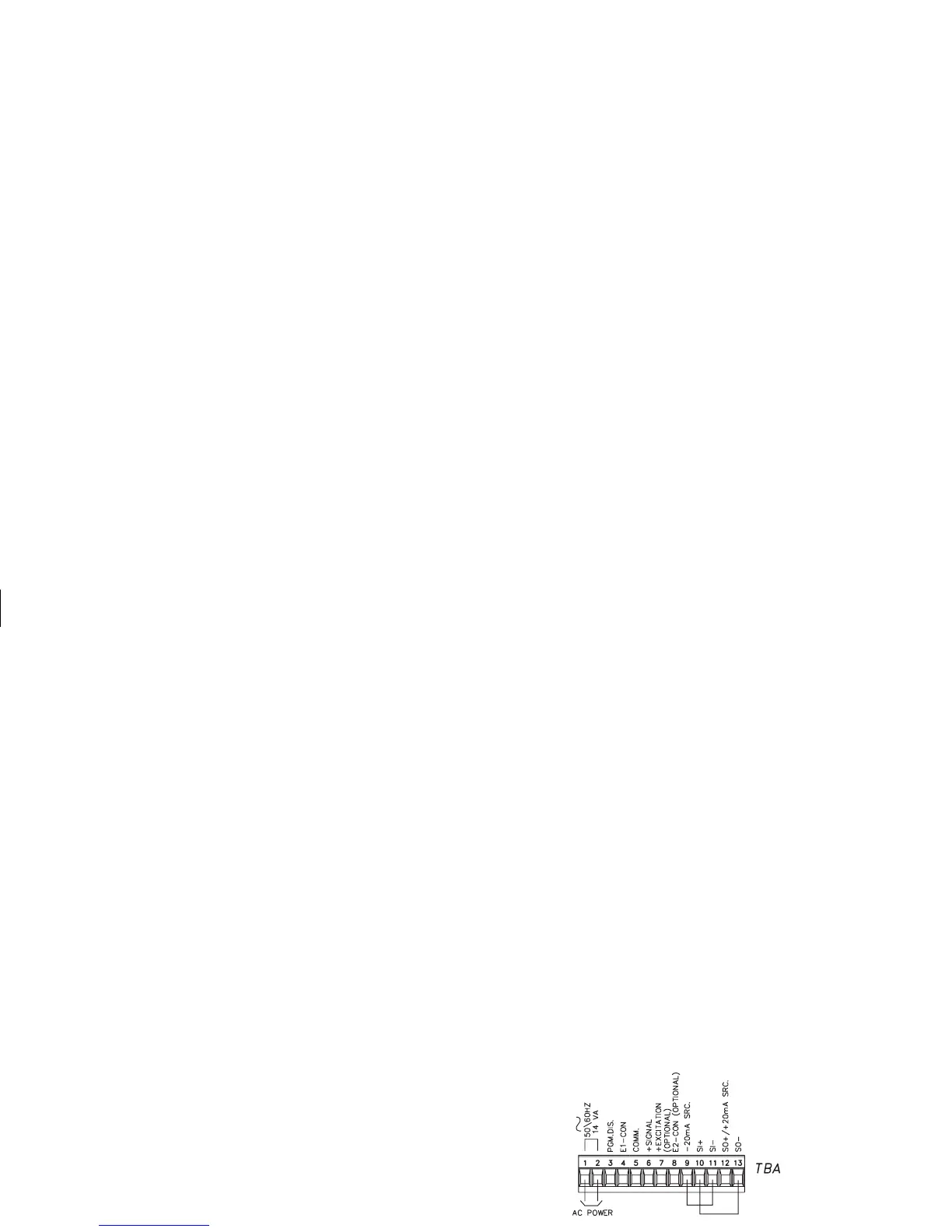

SERIAL HARDWARE (loop-back) DIAGNOSTICS

The internal serial communications hardware in the IMD1 can be tested to

verify proper operation. The procedure consists of connecting the Serial Input

(SI), Serial Output (SO), and 20 mA Source into a simple loop, and then

entering an access code.

Connect the IMD1 as shown below. Enter “Pro 9”, key-in “Code 39”, and

then press “P”. If the serial communication hardware is OK, “PASS” will be

displayed. Conversely, if there is an internal problem, “FAIL” will be

displayed. After the diagnostic test is complete, press “P” to return to “Pro 0”.

“CodE” < > “39”

-20-

Loading...

Loading...