E33-10 FPI Direct Vent Gas Insert | 13

|

13

installation

GAS PRESSURE

TESTING

The appliance must be isolated from the gas sup-

ply piping system by closing its individual manual

shut off valve during any pressure testing of the

gas supply piping system at test pressures equal

to or less than 1/2 psig. (3.45 kPa).

INSTALLATION INTO A SOLID FUEL

BURNING FIREPLACE OR FACTORY

BUILT FIREPLACE

The E33 Gas Inserts have been tested and ap-

proved to be vented into any masonry fireplace or

approved solid fuel burning factory built fireplace that

will allow the insert to physically fit into the firebox.

Refer to "Minimum Fireplace Dimensions" section

for minimum fireplace clearances.

If the factory built replace* height is too low for

your Insert, you may remove the smoke bae

plate, damper, refractory (rebricks), glass doors,

screen rails, screen mesh and log grates from the

factory built replace as long as these items are

saved and are reinstalled in the event that the Insert

is removed. The replace ue damper can be fully

blocked open or removed for installation of the gas

replace insert.

Smoke shelves, shields and baes may be removed

if attached by mechanical fasteners. If any part is

removed it must not weaken the structural integrity

of the factory built replace.

The replace and replace chimney must be clean

and in good working order and constructed of non-

combustible materials.

The surround panels should not seal ventilation

openings on the replace.

Chimney clean outs should t properly.

NOTE: Any alterations made to the listed solid fuel

burning factory built replace may void the listing

of the replace.

Cutting any sheet metal part of the replace, in

which the gas replace insert is to be installed is

prohibited.

*Check with your local inspector before commencing

with this installation.

Installer must mechanically attach the supplied

label to the inside of the rebox of the replace into

which the gas replace insert is installed.

"WARNING: This replace has been converted

for use with a gas replace insert only and cannot

be used for burning wood or solid fuels unless all

original parts have been replaced, and the replace

re-approved by the authority having jurisdiction."

FACTORY-BUILT (METAL) WOOD-

BURNING FIREPLACE

REQUIREMENTS

NOTE: Any parts that are removed must be removed

in a way that would allow them to be re-installed if

the insert is ever removed (removal of rivets or

screws is acceptable).

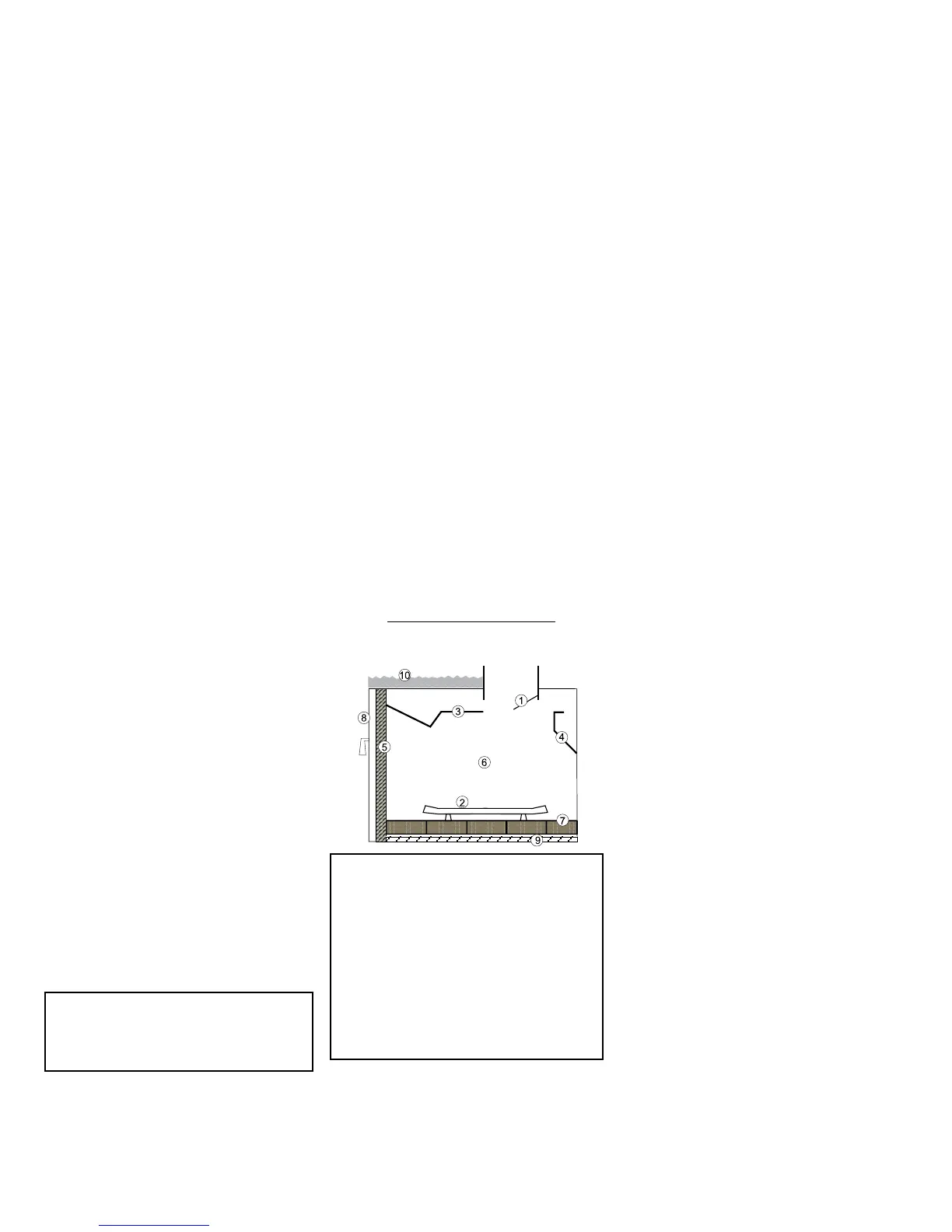

To reference parts—see illustration below.

Must be removed:

1 -Damper

2- Grate (with log set)

May be removed (if applicable):

3- Smoke shelf

4- Internal baes

5 - Screen

6 & 7 - Masonry lining or refractory

8 - Metal or glass doors

The replace must be permanently marked to

indicate that it has been altered and is no longer

suitable for burning solid fuel (wood), unless the

removed parts are re-installed. Cutting of any sheet

metal parts is prohibited.

May be removed (in certain cases):

9 -Metal oor of the rebox

10 - The insulation and any structured rigid frame

members must not be removed or altered (side and

top of door frame, side and top of the face of the

replace, metal sides, etc.).

If the factory-built replace has no gas access

hole(s) provided, an access hole of 1.5 inch (37.5

mm) or less may be drilled through the lower sides

or bottom of the rebox in a proper workmanship

like manner. This access hole must be plugged

with non-combustible insulation after the gas

supply line has been installed.

CAUTION:

Firebox oor removal is not covered under the

appliance safety standard (ANSI Z21.88, CSA

2.33) used in the safety certication of this ap-

pliance. The Intertek safety certication does

not apply to this method of installation. Before

installing the appliance using this method, contact

the Authority Having Jurisdiction to determine if

this installation is acceptable in your area. The

sheet metal base of the replace must be left in

place and a minimum 1/2" cement board sheet

placed under the entire length and width of the

appliance.

Loading...

Loading...