16 | E33-10 FPI Direct Vent Gas Insert

|

16

installation

GAS CONNECTION

1) If the appliance is to be installed into an existing

chimney system, thoroughly clean the masonry

or factory built replace.

2) The appliance is provided with an opening on

the left hand side of the control compartment.

A 3/8" NPT gas supply pipe must be brought

near this inlet hole.

3) Locate the center point where the vent will pass

through the chimney above the appliance. Move

the appliance into the exact location where it is

to be installed. Ensure that the Insert is level.

5) Install ashing.

6) Insert both liners into chimney, passing through

the damper opening.

7) Install termination cap.

8) Remove vent connector plate by removing

screw located on top/front of appliance.

9) Connect the marked end of the liner to the

exhaust collar of the vent connector plate

marked with an "E", seal connection with high

temperature silicone. Secure with 3 screws.

10) Connect the 2nd liner to the intake collar, seal

connection with high temperature silicone.

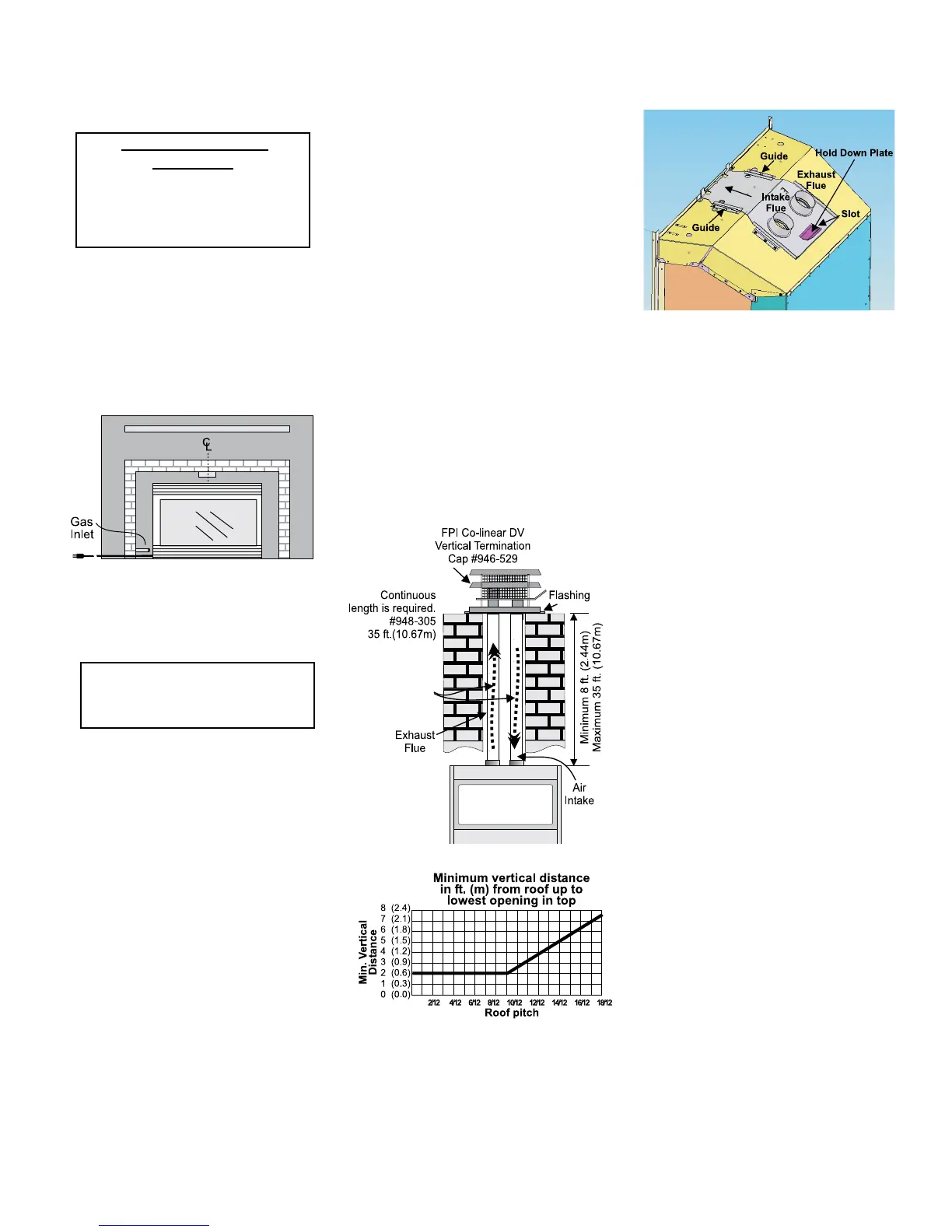

11) Align vent connector plate with guides on unit.

12) Slide unit into masonry opening, while ensuring

that the slot at the rear of the connector plate

mates up with the hold down plate on the unit.

13) Secure with Screw–removed from Step 8.

Secure with 3 screws.

NOTE:

1) Final gas connection should be made after

unit is in place to avoid damage to line when

pushing the unit into position.

2) Mill-pac may be used instead of high tempture

silicone and screws may be used instead of

gear clamps at connections of liner to inlet and

vent collars.

THE APPLIANCE MUST NOT BE

CONNECTED TO A CHIMNEY FLUE

SERVING A SEPARATE SOLID FUEL

BURNING APPLIANCE.

GAS CONNECTION

WARNING:

Only persons licensed to work

with gas piping may make the

necessary gas connections to

this appliance.

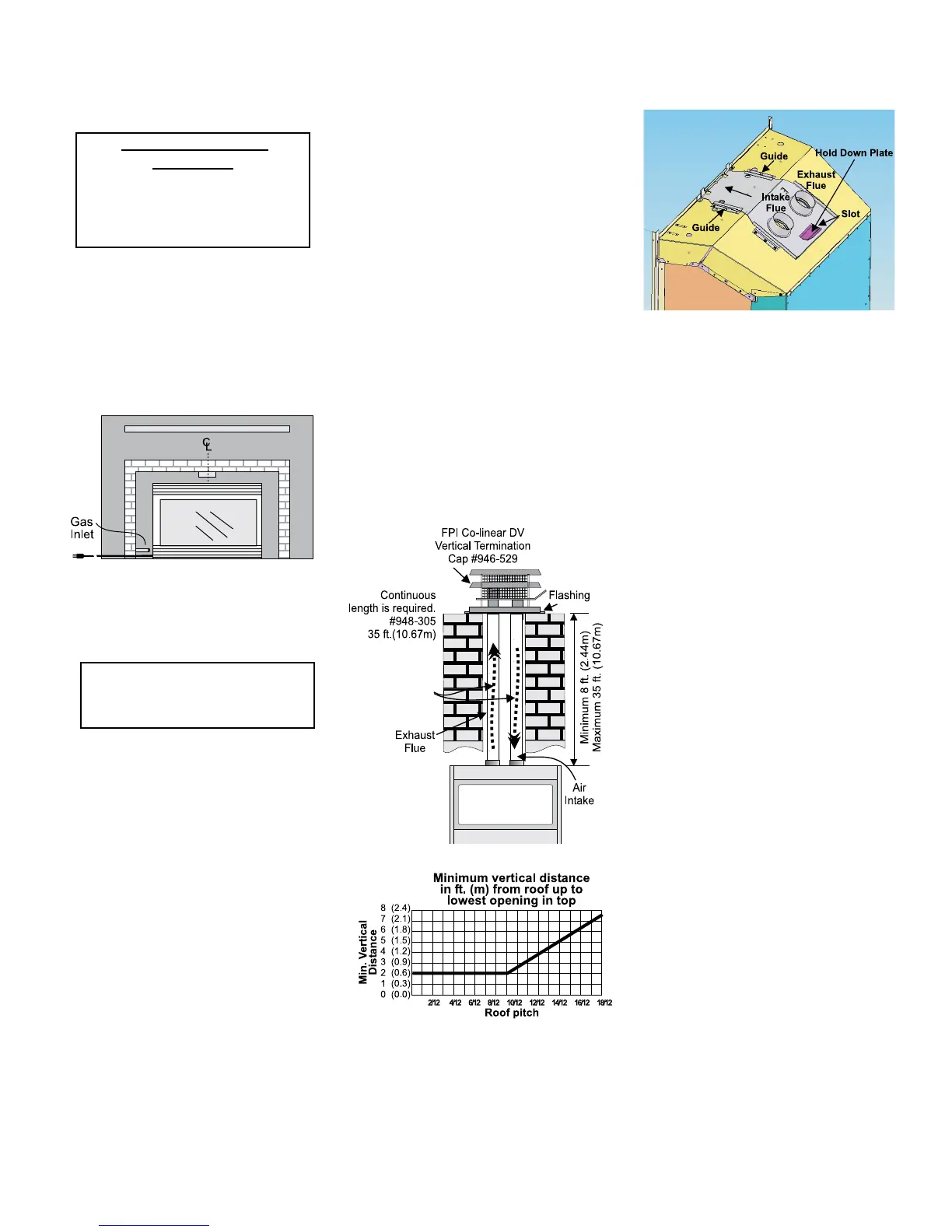

VENTING

This appliance is designed to be attached to two

3" (76mm) co-linear aluminium ex running the full

length of the chimney. The ue length must be a

minimum length of 8 ' (2.44m) and a maximum

of 35' (10.7m). See chart above for minimum

distances from roof. Periodically check that the

vent is unrestricted.

Masonry chimneys may take various contours

which the exible liner will accommodate. However,

keep the exible liner as straight as possible,

avoid unnecessary bending.

Part # Description

948-305 3" Flex - 35 ft.

946-529 Regency Co-linear DV Vertical

Termination Cap

Alternate Approved Caps

46dva-VC Vertical Termination Cap

46dva-VCH High Wind Cap

46dva-GK 3" Co-linear Adaptor with ashing

In areas of consistently high winds, we recommend

using the Simpson Dura-Vent System (46dva-GK

adapter and 46dva-VCH high-wind cap).

The Air Intake pipe must be attached to the inlet air

collar of the termination cap.

FLUE LINER

INSTALLATION

1) Cut the ex liner as required.

2) Mark the end of one liner with an "E" to

indicate Exhaust.

3) Connect the other end of the above liner to

the exhaust side of the termination adaptor,

seal connection with high temperature silicone.

Secure with 3 screws.

4) Connect the 2nd liner to the inlet side of the

adaptor, seal connection with high temperature

silicone. Secure with 3 screws.

Loading...

Loading...