3-15

www.renishaw.com/nc4

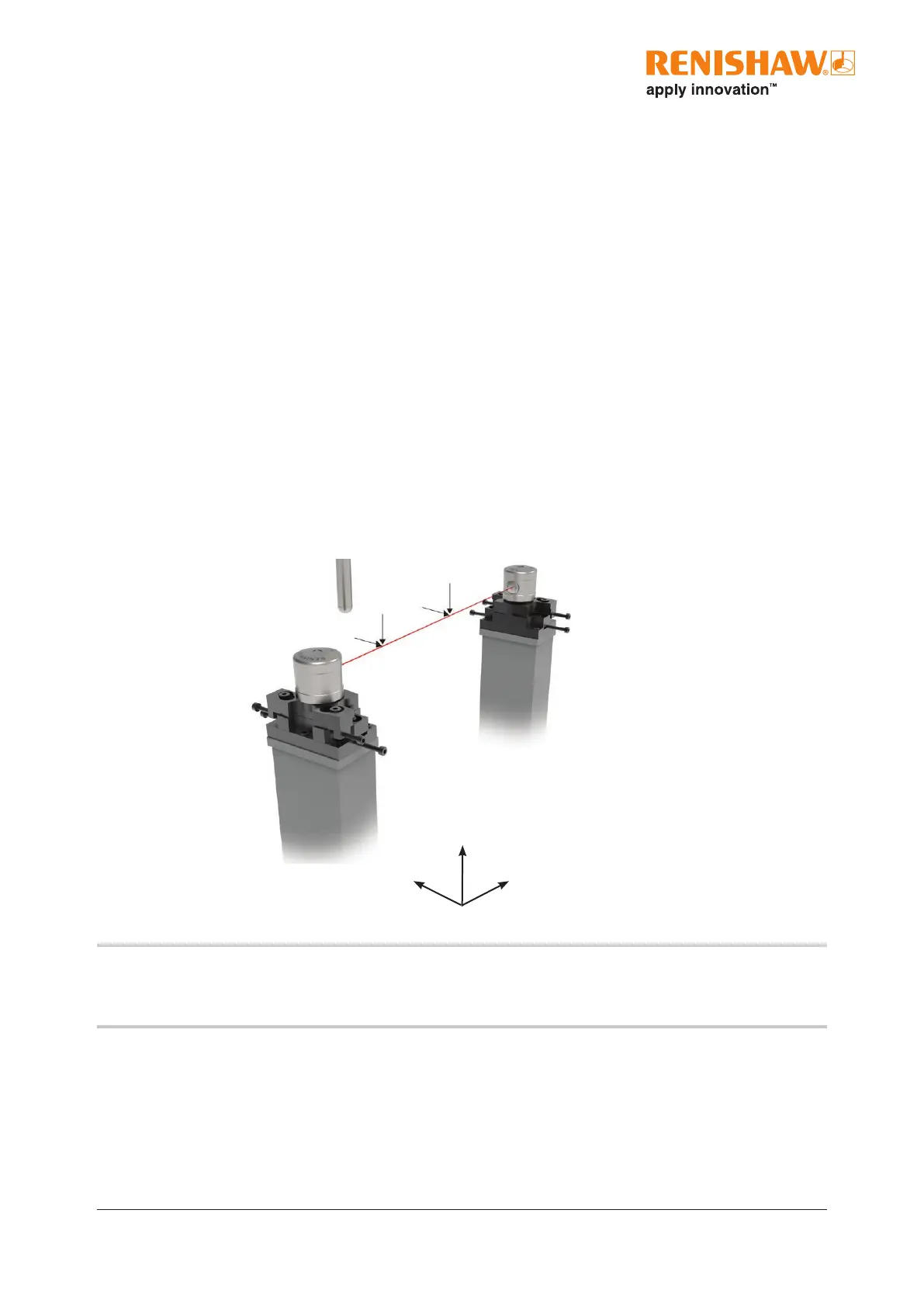

Alignment tolerances

The tolerances to which a tool can be set are dependent on the parallelism of the laser beam to the

machine axes.

Tool setting applications

Over a span of 100 mm (3.94 in), the following alignment accuracies are recommended:

Spindle axis (P2 – P1): ≤ 10 μm (0.39 μin)

Radial axis (P2 – P1): ≤ 1 mm (0.039 in)

These values are sufcient for the majority of tool setting applications.

Tool breakage detection applications

Over a span of 100 mm (3.94 in), the following alignment accuracies are recommended:

Spindle axis (P2 – P1): ≤ 0.2 mm (0.008 in)

Radial axis (P2 – P1): ≤ 1 mm (0.039 in)

These values are sufcient for the majority of tool breakage applications.

P1

P2

Spindle axis

Beam

axis

Radial

axis

NOTE: For best measurement performance, Renishaw recommends aligning NC4 units using a ball-nosed

cylinder-type calibration tool. A mobile app (NC4 app) is available for step-by-step instructions on NC4 unit

alignment (for more information, see page 3-10, “Machine tool apps”).

Loading...

Loading...