5-4 Instructions for Use Rexroth EcoDrive 03 DKC**.3-040...200

DOK-ECODR3-DKC40*200UL-IB01-EN-P

Note: The input 0 V is connected directly to the device potential. The

utilization of an insulation monitoring for +24 V and 0 V against

device is therefore not possible!

wire cross section: min. 1 mm²

for looping through: min. 2,5 mm²

wire routing: parallel if possible

Max. allowed inductance between 24V

source and X1:

100 µH

(equals about 2 x 75 m)

Note: If the cross sections of the lines for looping through the control

voltage are too small, the terminals can be damaged.

Note:

• Exceeding allowed control voltage generates error

message "+24 volt error". (=> See also firmware functional

description.)

• Control voltage failure causes the running motor to coast

torque-free (without brake).

DANGER

Dangerous movements due to unbraked

coasting of motor with control voltage failure!

⇒

Personnel should not remain within the area of the

machine with moving parts. Possible preventive

steps against unauthorized access are:

– protective fencing

– bars

– covers

– light barriers

⇒

The fences must be able to withstand the maximum

possible force that the machine can generate.

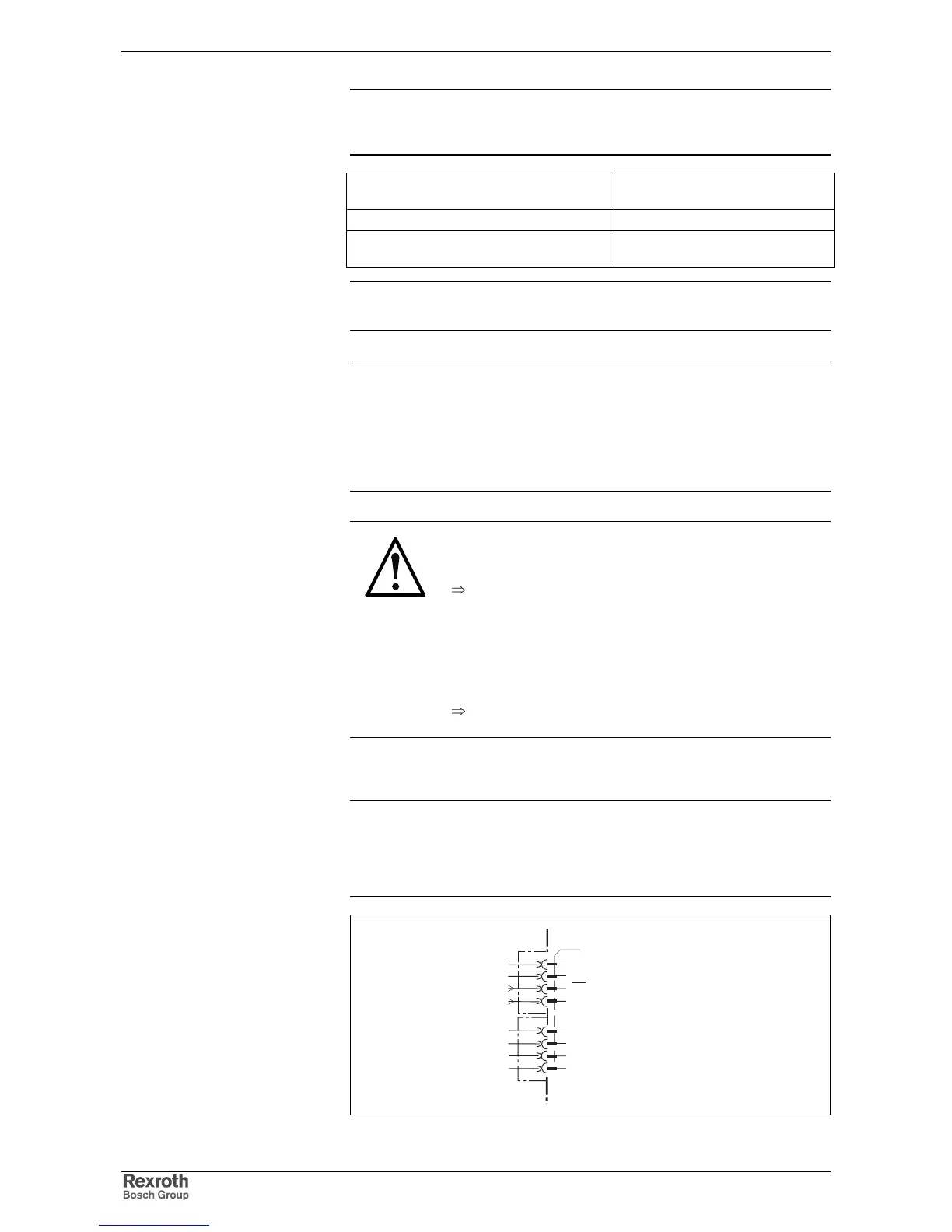

Drive halt (AH) and Drive enable (RF)

Note:

• Inputs work with inactive bus communication.

• Inputs don't work with active bus communication (SERCOS

interface, Profibus-DP, ...).

AP5270F1.FH7

AH

drive halt

RF

drive enable

X1

2

1

3

4

5

8

7

6

device-external device-internal

Fig. 5-8: Connections for drive halt and drive enable

wire

+24V and 0V:

Connection

AH and RF:

Loading...

Loading...