23

20041904

Installation

5.11 Gas feeding

5.11.1 Gas feeding line

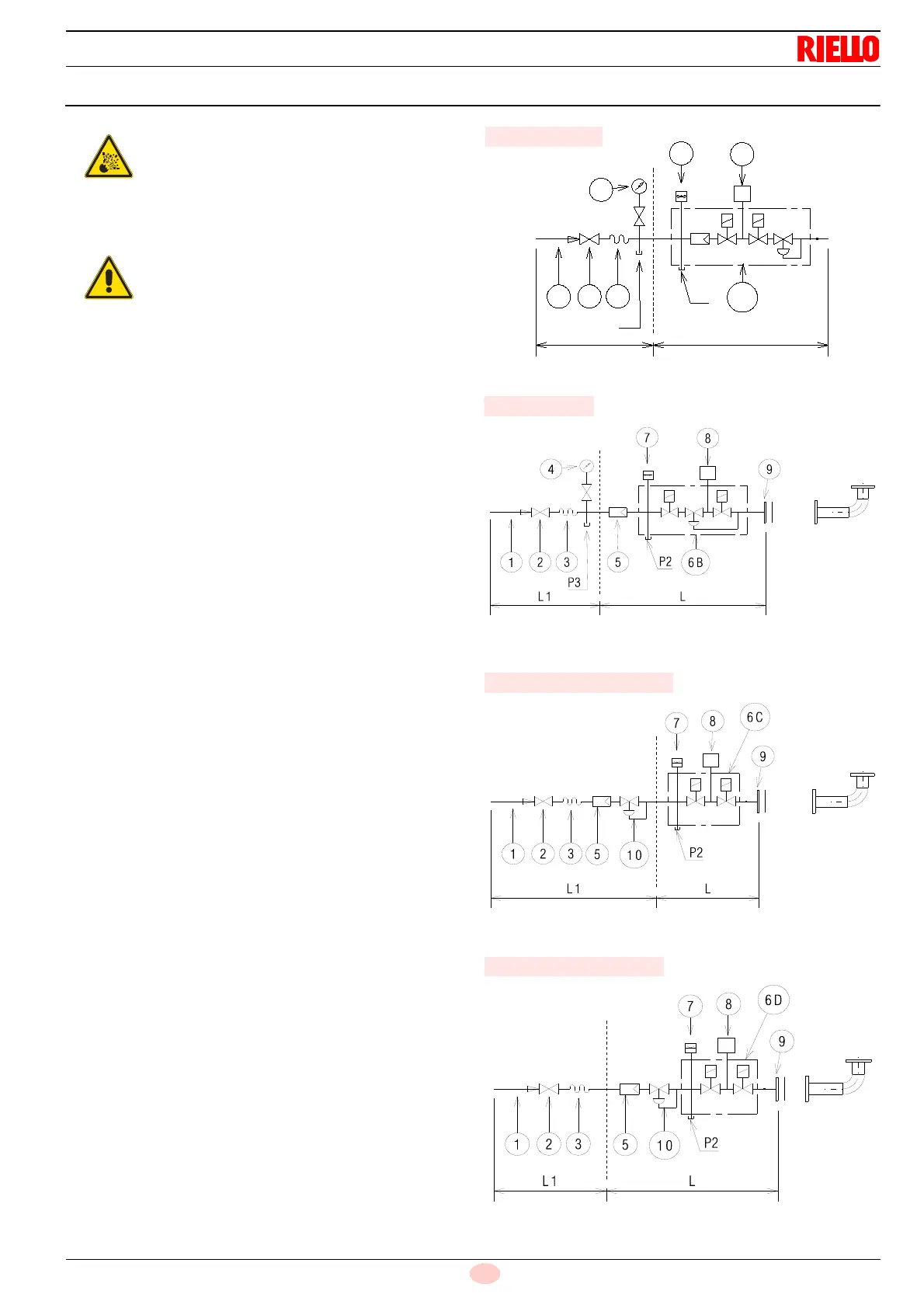

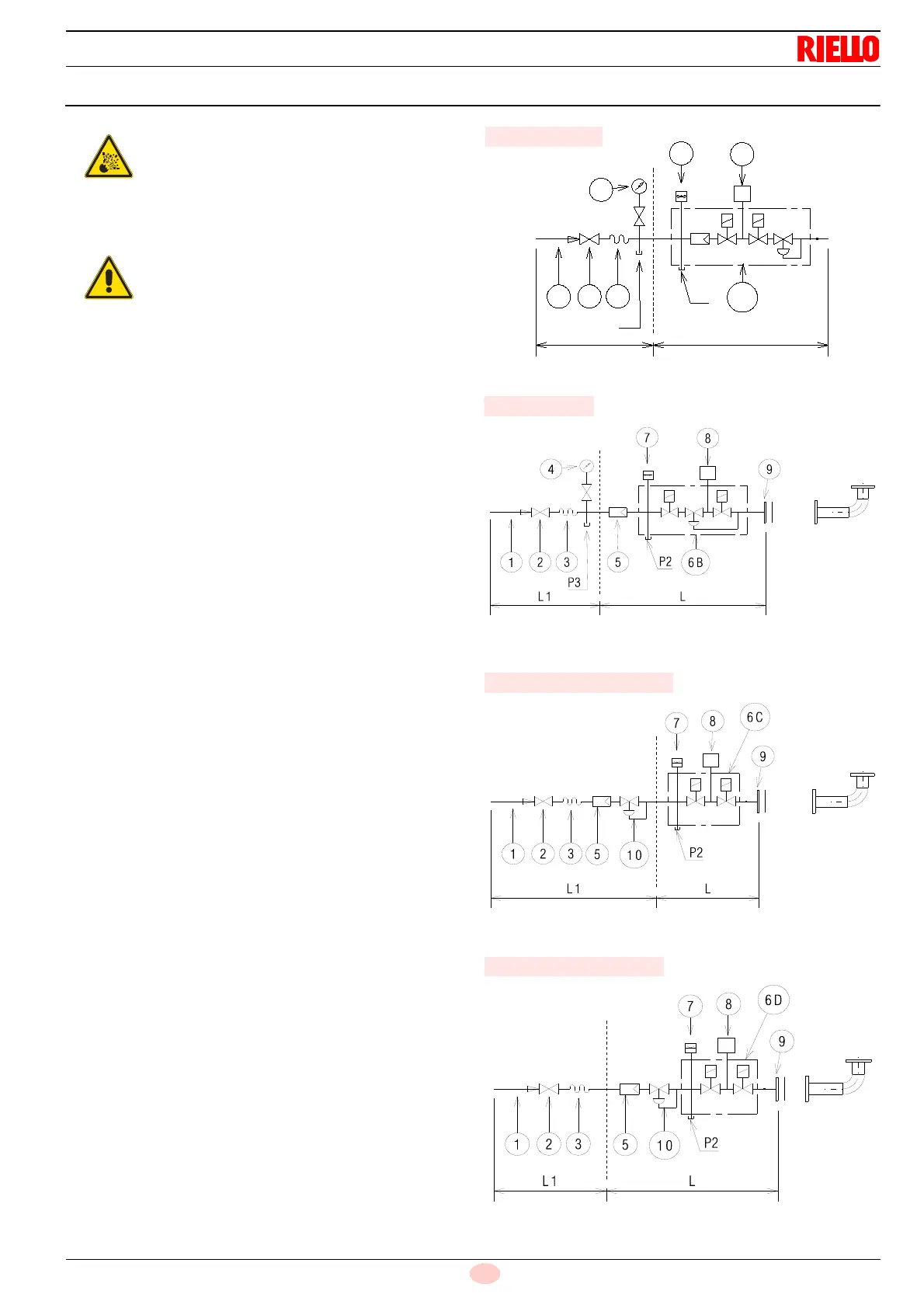

Key (Fig. 18 - Fig. 19 - Fig. 20 - Fig. 21)

1 Gas input pipe

2 Manual valve

3 Vibration damping joint

4 Pressure gauge with pushbutton cock

5 Filter

6A Includes:

– Filter

– working valve

– safety valve

– pressure adjuster

6B Includes:

– working valve

– safety valve

– pressure adjuster

6C Includes

– safety valve

– working valve

6D Includes:

– safety valve

– working valve

7 Minimum gas pressure switch

8 Leak detection device, supplied as an accessory or incorpo-

rated, based on the gas train code. In compliance with the

EN 676 standard, the leak detection control is compulsory for

burners with maximum outputs over 1200 kW.

9 Gasket, for “flanged” versions only

10 Pressure adjuster

P2 Upstream pressure of valves/adjuster

P3 Upstream pressure of the filter

L Gas train supplied separately

L1 The responsibility of the installer

Explosion danger due to fuel leaks in the pres-

ence of a flammable source.

Precautions: avoid knocking, attrition, sparks and

heat.

Make sure that the fuel interception tap is closed

before performing any operation on the burner.

The fuel supply line must be installed by qualified

personnel, in compliance with current standards

and laws.

Fig. 18

D11854

MBC “threaded”

Fig. 19

MBC “flanged”

20065706

Fig. 20

DMV “flanged or threaded”

20065609

Fig. 21

CB “flanged or threaded”

20065707

Loading...

Loading...