29

20041904

Start-up, calibration and operation of the burner

6.6 Pressure switch adjustment

6.6.1 Air pressure switch - check CO

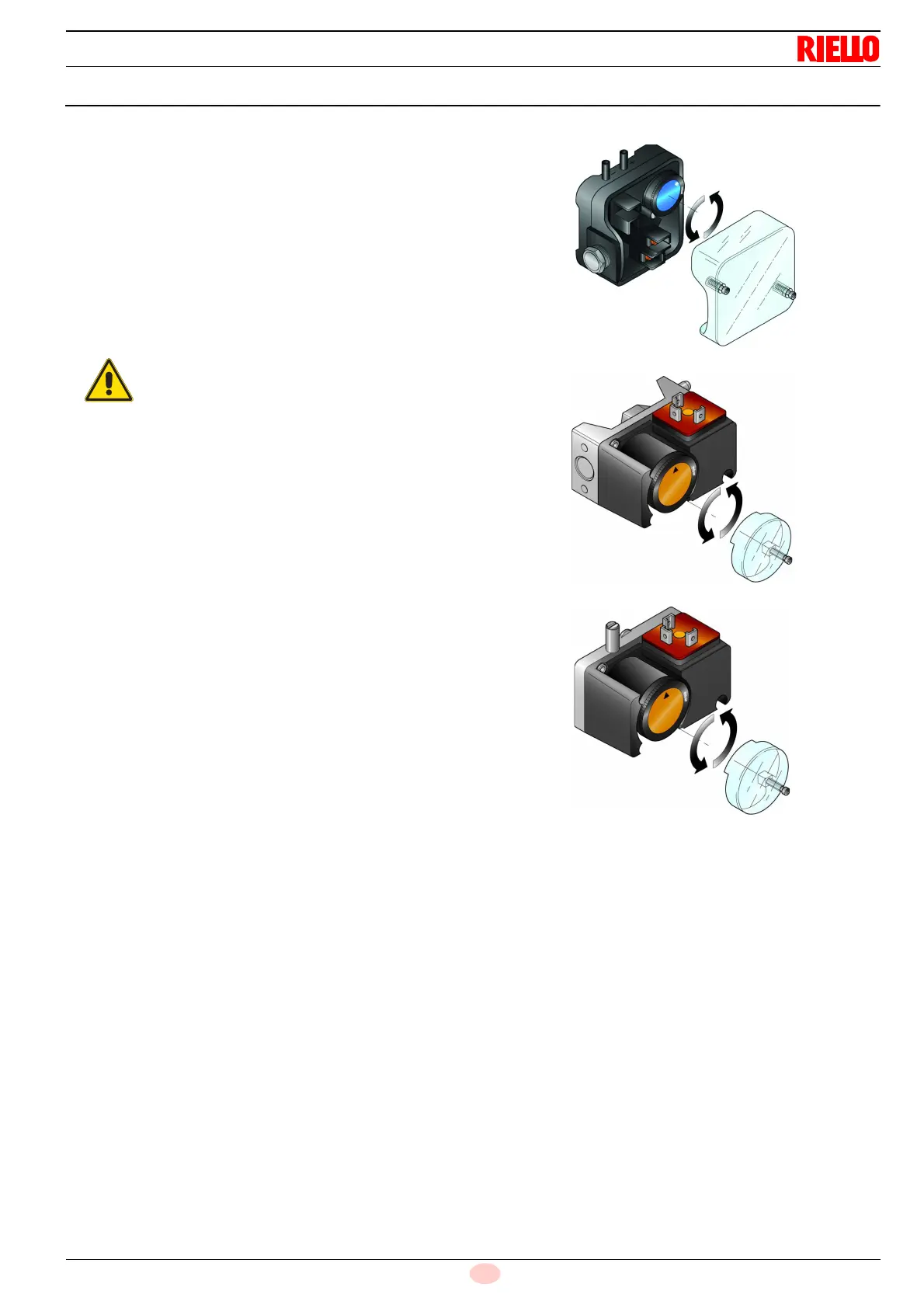

Adjust the air pressure switch (Fig. 27) after performing all other

burner adjustments with the air pressure switch set to the start of

the scale.

With the burner operating at MIN output, increase adjustment

pressure by slowly turning the relative knob clockwise until the

burner locks out.

Then turn the knob anticlockwise by about 20% of the set point

and repeat burner start-up to ensure it is correct.

If the burner locks out again, turn the knob anticlockwise a little

bit more.

On RS

300-400-500

/E BLU burners the air pressure switch is fit-

ted in a “differential” mode, that is, with two pipes connected to

the specific pressure test points “+” and “-” 22)-23 Fig. 4 on

page 13).

On RS

650-800

/E BLU burners the air pressure switch is fitted in

an “absolute” mode, that is, connected only to the pressure test

point “+” 22) Fig. 4 on page 13).

6.6.2 Maximum gas pressure switch

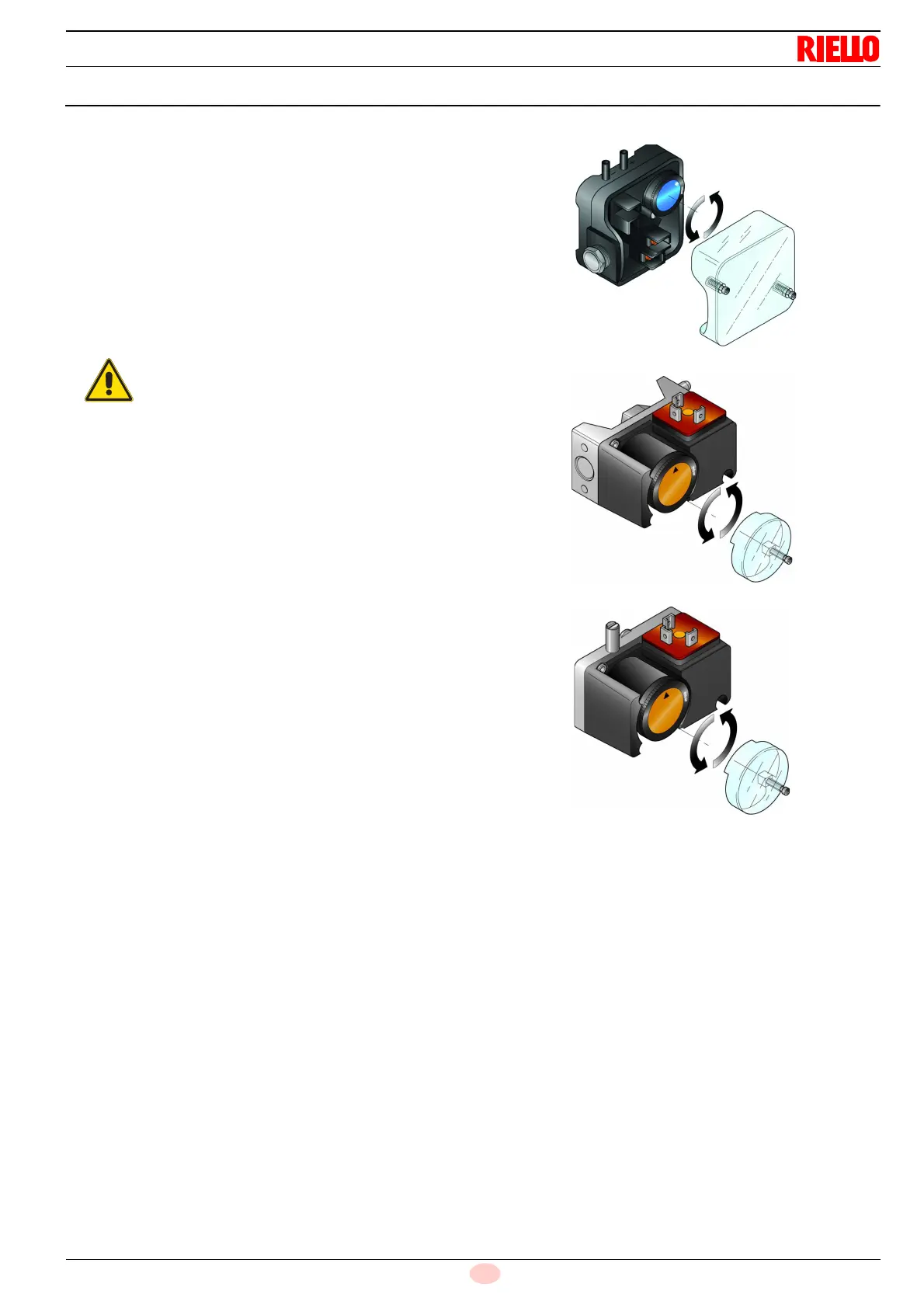

Adjust the maximum gas pressure switch (Fig. 28) after perform-

ing all other burner adjustments with the maximum gas pressure

switch set to the end of the scale.

With the burner operating at maximum output, lower adjustment

pressure by slowly turning the relative knob anticlockwise until

the burner locks out.

Turn the knob clockwise by 2 mbar and repeat the start-up of the

burner.

If the burner locks out again, turn the knob clockwise again by 1

mbar.

6.6.3 Minimum gas pressure switch

Adjust the minimum gas pressure switch (Fig. 29) after perform-

ing all the other burner adjustments with the pressure switch set

to the start of the scale.

With the burner operating at maximum output, increase adjust-

ment pressure by slowly turning the relative knob clockwise until

the burner locks out.

Then turn the knob anticlockwise by 2 mbar and repeat burner

start-up to ensure it is uniform.

If the burner locks out again, turn the knob anticlockwise again by

1 mbar.

In conformity with the standard, the air pressure

switch must prevent the air pressure falling below

80% of the adjusted value and the CO in the flue

gases exceeding 1% (10,000 ppm).

To check this, insert a combustion analyser into

the chimney, slowly close the fan suction inlet (for

example with cardboard) and check that the burn-

er locks out, before the CO in the fumes exceeds

1%.

Loading...

Loading...