25

20041904

Installation

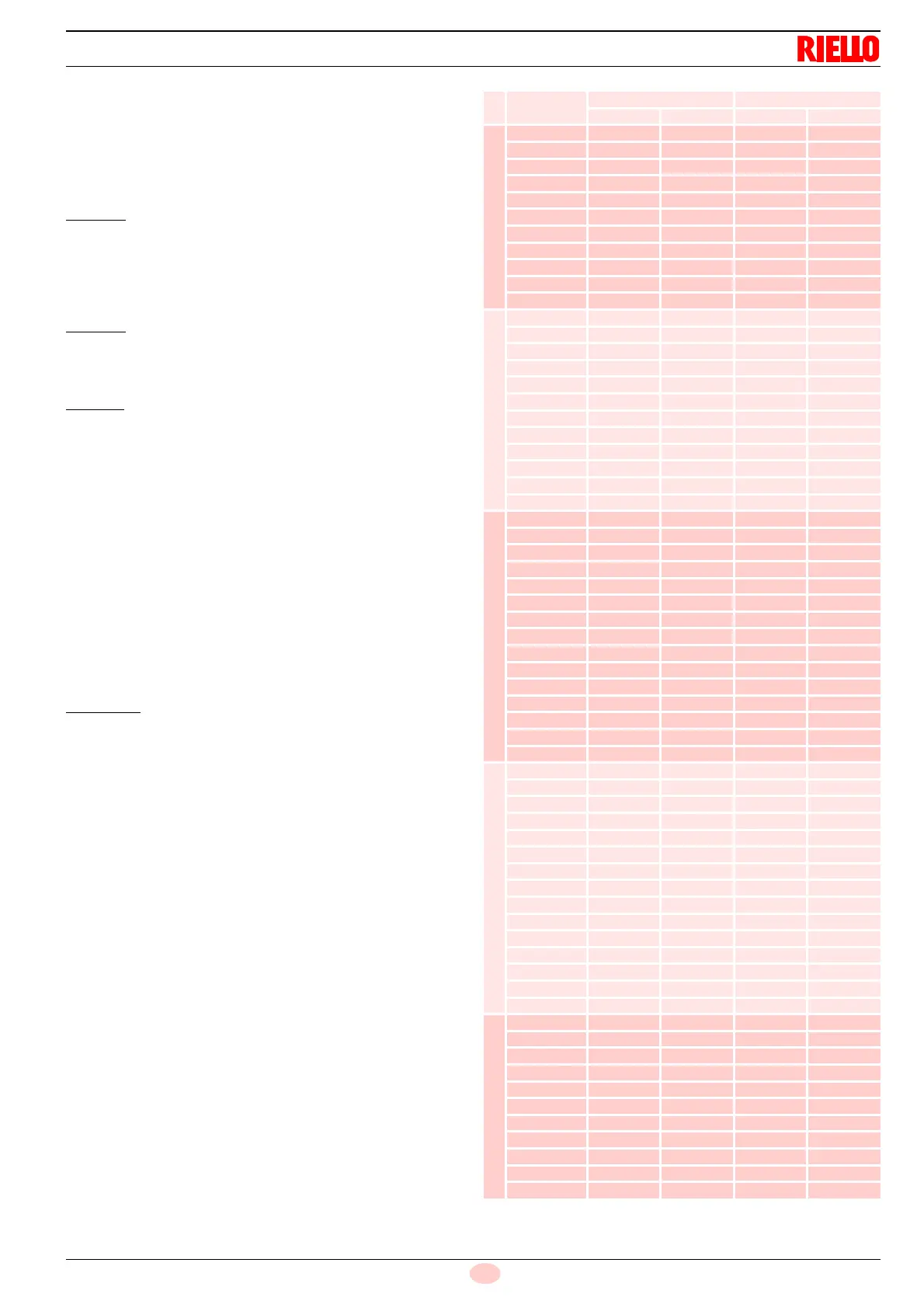

5.11.4 Gas pressure

Tab. N indicates the minimum pressure drops along the gas sup-

ply line, depending on the maximum burner output.

The values shown in Tab. N refer to:

– Natural gas G 20 NCV 9.45 kWh/Sm

3

(8.2 Mcal/Sm

3

)

– Natural gas G 25 NCV 8.13 kWh/Sm

3

(7.0 Mcal/Sm

3

)

Column 1

Pressure drop on combustion head.

Gas pressure measured at the test point P1) (Fig. 22), with:

• Combustion chamber at 0 mbar;

• Burner working at maximum output;

• Combustion head adjusted as in page 21.

Column 2

Pressure loss at gas butterfly valve 10) (Fig. 20) with maximum

opening: 90°.

Calculate the approximate maximum output of the burner in this

way:

– subtract the combustion chamber pressure from the gas

pressure measured at test point P1) (Fig. 22).

– Find, in the table Tab. N related to the burner concerned, the

pressure value closest to the result of the subtraction.

– read the corresponding output on the left.

Example for RS 650/E BLU with G20 natural gas:

Maximum output operation

Gas pressure at test point P1)(Fig. 22) = 25.6 mbar

Pressure in combustion chamber = 2 mbar

25.6 - 2 = 23.6 mbar

A pressure of 23.6 mbar, column 1, corresponds in the table Tab.

N to an output of 4,500 kW.

This value serves as a rough guide; the effective output must be

measured at the gas meter.

To calculate the required gas pressure at test point P1) (Fig. 22),

set the MAX output required from the burner operation:

– find the nearest output value in the table Tab. N for the burner

in question.

– read, on the right (column 1), the pressure at the test point

P1)(Fig. 22).

– Add this value to the estimated pressure in the combustion

chamber.

Example for RS 650/E BLU with G20 natural gas:

Required burner maximum output operation: 4500 kW

Gas pressure at an output of 4,500 kW = 23.6 mbar

Pressure in combustion chamber = 2 mbar

23.6 + 2 = 25.6 mbar

Pressure required at test point P1)(Fig. 22).

Tab. N

kW

1 ∆

p (mbar)

2 ∆

p (mbar)

G 20 G 25 G 20 G 25

RS 300/E BLU

1245 7.8 11.6 1.3 2.0

1500 9.4 13.9 1.9 2.8

1750 10.9 16.2 2.6 3.9

2000 12.4 18.5 3.4 5.0

2250 13.0 19.5 4.3 6.4

2500 13.7 20.4 5.3 7.9

2750 14.3 21.4 6.4 9.5

3000 15.0 22.4 7.6 11.3

3250 17.6 26.2 8.9 13.3

3500 20.2 30.1 10.3 15.4

3800 23.3 34.8 12.2 18.2

RS 400/E BLU

1800 6.3 9.3 2.9 4.3

2000 7.9 11.7 3.5 5.3

2250 9.9 14.7 4.5 6.7

2500 11.9 17.7 5.5 8.2

2750 13.9 20.7 6.7 10.0

3000 15.9 23.7 8.0 11.9

3250 17.9 26.7 9.3 13.9

3500 19,7 29.4 10.8 16.2

3750 21.1 31.4 12.4 18.6

4000 22.4 33.5 14.2 21.1

4250 27.4 40.8 16.0 23.8

4500 32.5 48.4 17.9 26.7

RS 500/E BLU

2500 11.5 17.2 0.6 0.8

2600 12.3 18.4 0.6 0.9

2800 13.9 20.8 0.7 1.0

3000 15.5 23.2 0.8 1.2

3200 17.1 25.5 0.9 1.4

3400 18.7 27.9 1.0 1.5

3600 20.5 30.6 1.2 1.7

3800 22.5 33.6 1.3 1.9

4000 24.5 36.6 1.4 2.1

4200 26.5 39.5 1.6 2.3

4400 28.5 42.5 1.7 2.6

4600 30.5 45.5 1.9 2.8

4800 33.0 49.2 2.0 3.1

5000 35.5 53.0 2.2 3.3

5200 38.0 56.7 2.4 3.6

RS 650/E BLU

3000 11.0 13.7 1.0 1.5

3250 13.1 16.7 1.1 1.7

3500 15.2 19.8 1.3 2.0

3750 17.3 22.8 1.5 2.3

4000 19.4 25.8 1.7 2.6

4250 21.5 28.9 1.9 2.9

4500 23.6 31.9 2.1 3.3

4750 25.7 35.1 2.4 3.7

5000 28.4 39.3 2.6 4.0

5250 31.2 43.5 2.9 4.5

5500 33.9 47.7 3.2 4.9

5750 36.6 51.9 3.5 5.4

6000 39.3 56.0 3.8 5.8

6250 42.1 60.2 4.1 6.3

6500 44.8 64.4 4.5 6.8

RS 800/E BLU

3500 9.4 12.8 0.6 0.7

4000 12.8 17.7 0.7 0.9

4500 16.2 22.5 0.9 1.1

5000 19.6 27.3 1.2 1.4

5500 23.0 32.1 1.4 1.7

6000 26.4 37.0 1.7 2.0

6500 30.9 44.7 2.0 2.3

7000 35.5 52.4 2.3 2.7

7500 40.9 59.8 2.6 3.1

8000 46.3 67.1 3.0 3.5

8060 47.0 68.0 3.0 3.5

Loading...

Loading...