31

20041904

Maintenance

Combustion

If the combustion values measured before starting maintenance

do not comply with applicable legislation or do not indicate effi-

cient combustion, consult the Tab. O or contact our Technical

Support Service to implement the necessary adjustments.

It is advisable to set the burner according to the type of gas used

and following the indications in Tab. O.

Tab. O

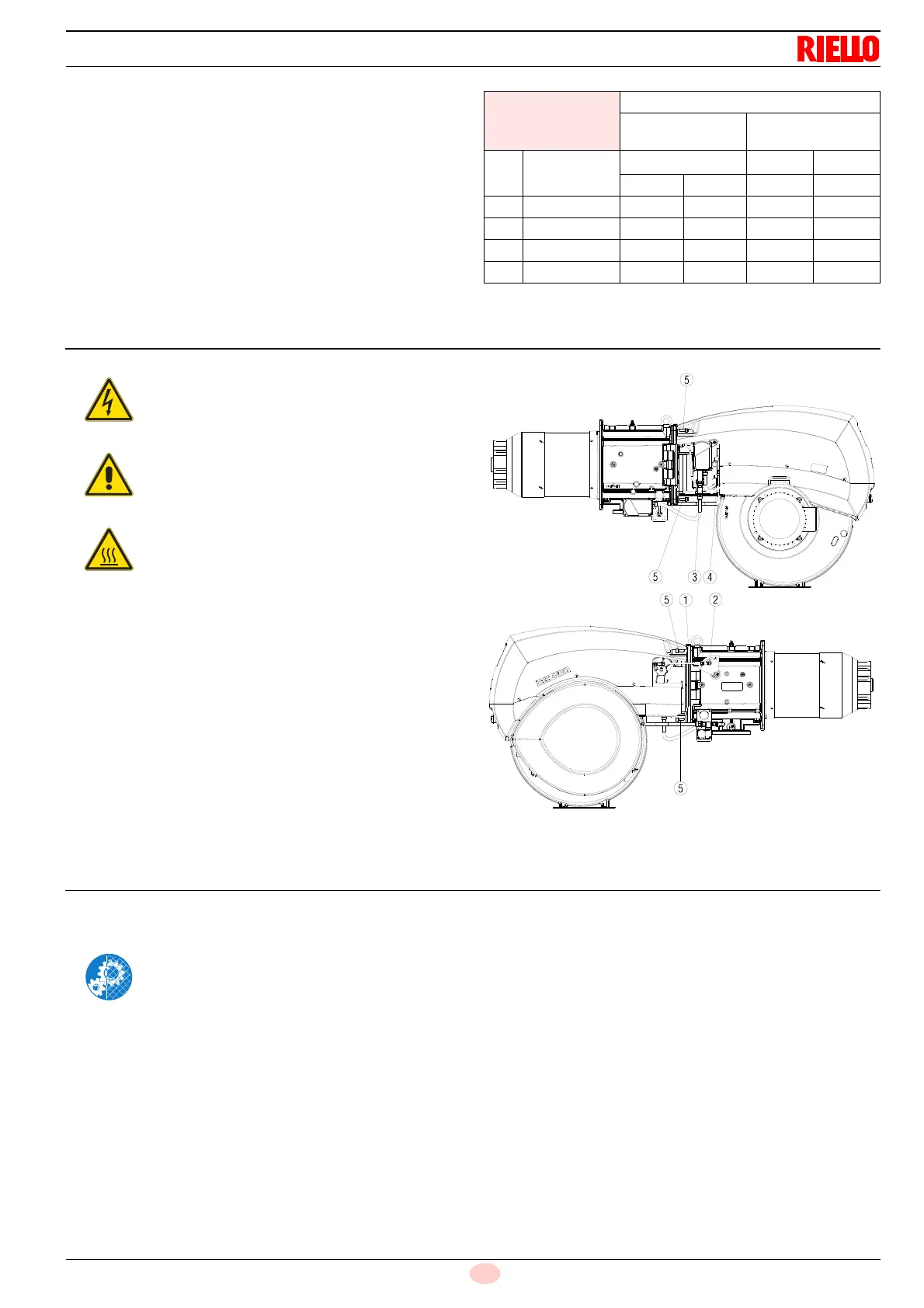

7.3 Opening the burner

➤

Remove the tie-rod 1)(Fig. 31) of the head movement lever,

undoing the nut 2).

➤

Disconnect the socket 3) of the gas servomotor.

➤

Disconnect the socket 4) of the gas pressure switch.

➤

Remove the screws 5).

At this point, it is possible to open the burner on the hinge.

7.4 Closing the burner

Refit following the steps described but in reverse order; refit all

burner components as they were originally assembled.

EN 676

Air excess

Max. output

λ ≤ 1.2

Min. output

λ ≤ 1.3

GAS

CO

2

theoretic

al max. 0% O

2

CO

2

% Calibration

CO

NO

X

λ = 1.2 λ = 1.3 mg/kWh mg/kWh

G 20 11.7 9.7 9.0

≤

100

≤

170

G 25 11.5 9.5 8.8

≤

100

≤

170

G 30 14.0 11.6 10.7

≤

100

≤

230

G 31 13.7 11.4 10.5

≤

100

≤

230

Disconnect the electrical supply from the burner

by means of the main system switch.

Close the fuel interception tap.

Wait for the components in contact with heat

sources to cool down completely.

After carrying out maintenance, cleaning or

checking operations, reassemble the hood and all

the safety and protection devices of the burner.

Loading...

Loading...