Rinnai I-Series Condensing Boiler Combi Manual 103

700

PC Board

• PC Board circuit error.

• Replace PC Board.

710

Solenoid Valve Circuit

• Ensure Dip switch 5 on the PC Board is in

the OFF posion (default).

• Ensure the gas control wire is not loose or

damaged.

• Replace the PC Board.

720

Flame Rod

• Check the ame rod and wire for damage.

• Ensure the ame rod and wire are not wet.

• If there is no issue with the ame rod or

wiring, replace the PC Board.

890

Freeze Issue

• The boiler checks the heat exchanger

temperature at the me of operaon.

• If the temperature is too low, an error will

occur.

• Check if there is freezing in the boiler or

CH system.

999

PC Board Mismatch

• This code occurs when the PC Board and

the internal logic do not match.

• Check if the soware versions of the board

and operaon board do not match.

LC

Scale Buildup in Heat Exchanger

• Flush the DHW plate heat exchanger.

• The LC code will reset automacally when

scaling is removed. If the LC code remains,

check the DHW thermistor, ow sensor or

boiler pump.

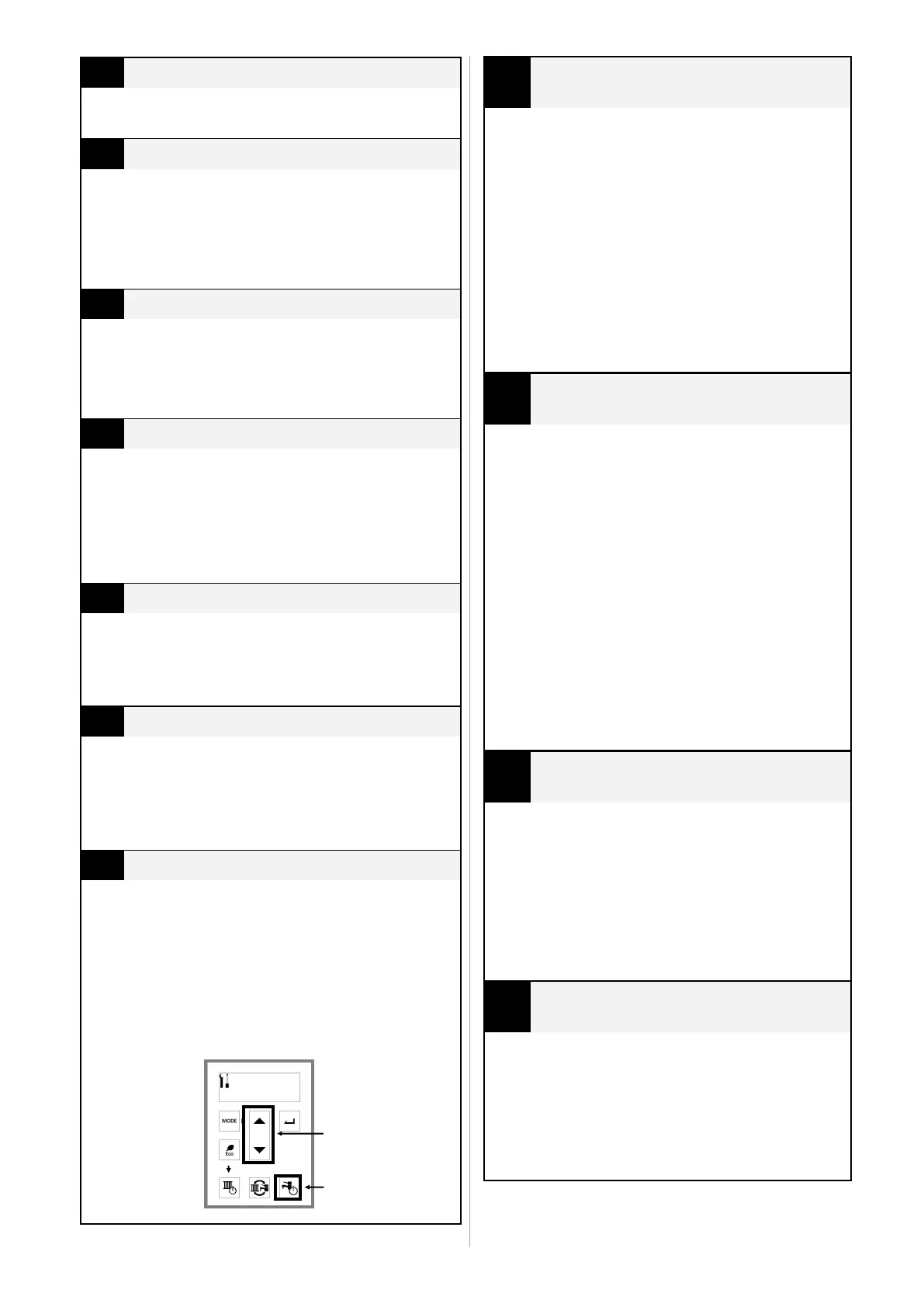

FFF

Maintenance Indicator

• This code is a placeholder in diagnosc

code history indicang a service provider

performed maintenance or service.

• Enter this code aer performing service by

pressing and holding the Up buon, then

press and hold the Down buon, and then

press the DHW buon simultaneously. FFF

will appear on the display.

No

Code

Nothing happens when DHW water ow is

acvated

• Verify the minimum ow rate required

to re the boiler is seen.

• Measure the resistance of the ow

control sensor.*

• Clean the inlet water supply lter.

• On new installaons, ensure the hot and

cold water lines are not reversed.

• Conrm the inlet water temperature is

not too high.

• Ensure the integrated boiler pump

operates properly.

• Ensure the DHW operaon switch is on.

No

Code

Decreasing or uctuang DHW water ow

volume

• Ensure the gas pressure is proper.

• Ensure the water pressure is proper.

• Ensure the inlet water lter for DHW is

clean.

• Ensure there is not lime scale buildup

present.

• Ensure the vent and vent sengs are

properly set up.

• If a DHW recirculaon system is used,

the DHW ow volume may vary slightly.

• Ensure all air has been purged from the

system.

• Ensure the pump is set to speed 3.

• During simultaneous CH and DHW

operaon mode, it is possible to see

decreased DHW ow.

No

Code

Fluctuang DHW outgoing temperature

• Ensure the gas pressure is proper.

• Ensure the water pressure is proper.

• Ensure the DHW thermistor, ow servo,

and bypass servo are in good condion.

• Ensure the inlet lter for DHW is clean.

• If a DHW recirculaon system is used,

the DHW temperature may vary slightly.

• Ensure all air is removed from the

system.

No

Code

Boiler does not start heang with a heang

demand present

• Supply temperature or return

temperature inside the boiler may be

too hot.

• Ensure the pump operates properly.

• If there is a demand immediately aer

using DHW, wait at least three minutes

for operaon.

* See “Electrical Diagnoscs” on Technical Data

Sheet located on inside front cover of boiler.

Up and Down

E;FFF

Press the DHW

buon

Loading...

Loading...