Rinnai I-Series Condensing Boiler Combi Manual 17

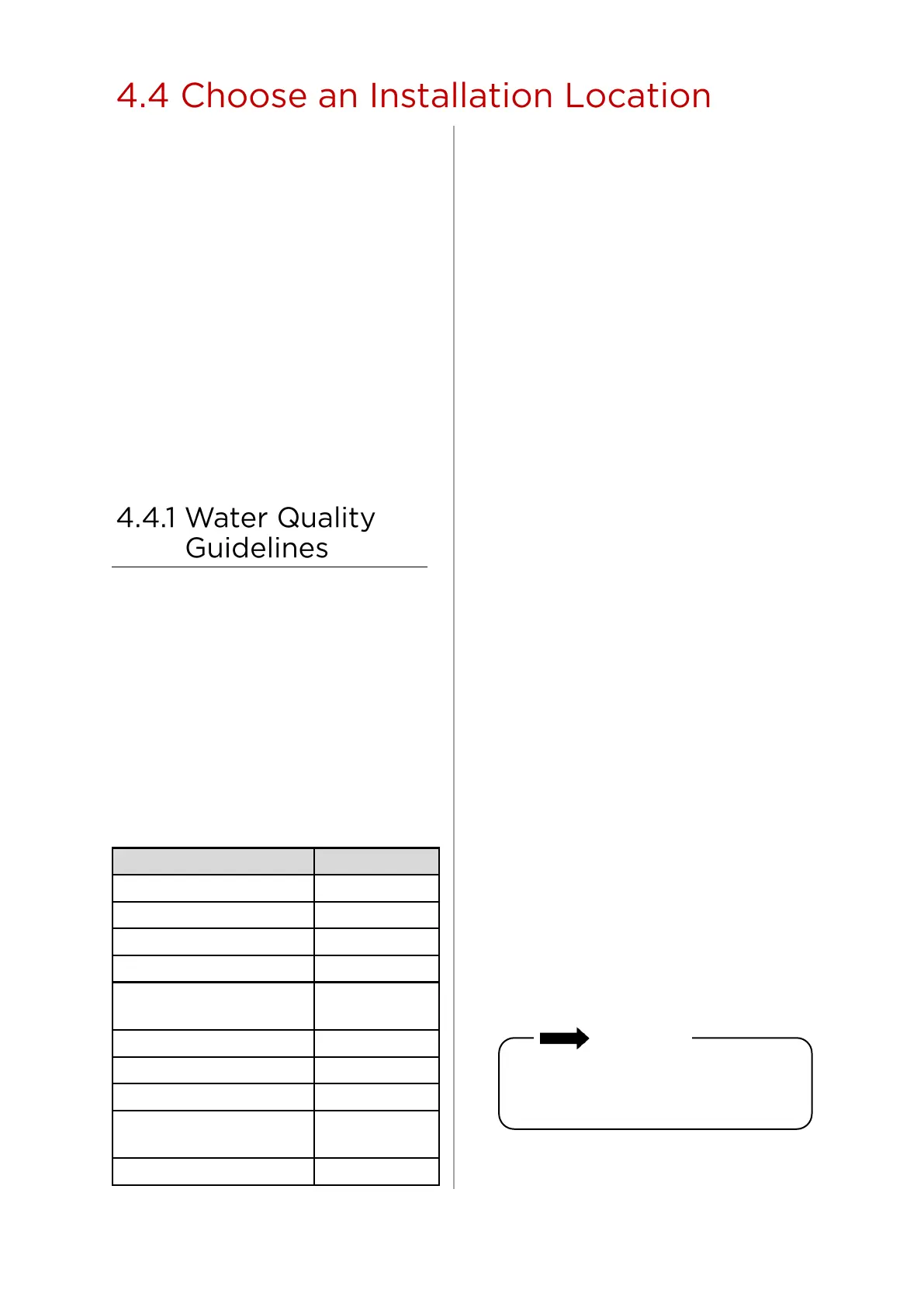

Contaminant Maximum Level

Total Hardness Up to 200 mg/L

Aluminum * Up to 0.2 mg/L

Chlorides * Up to 250 mg/L

Copper * Up to 1.0 mg/L

Dissolved Carbon Dioxide

(CO2)

Up to 15.0 mg/L

Iron * Up to 0.3 mg/L

Manganese * Up to 0.05 mg/L

pH * 6.5 to 8.5

TDS (Total Dissolved

Solids) *

Up to 500 mg/L

Zinc * Up to 5 mg/L

Consideraon of care for your boiler should

include evaluaon of water quality.

• The water must be potable, free of

corrosive chemicals, sand, dirt, or other

contaminants.

• It is up to the installer to ensure the

water does not contain corrosive

chemicals or elements that can aect or

damage the boiler.

• Water that contains chemicals

exceeding the levels below can damage

the boiler.

* Source: Part 143 Naonal Secondary Drinking Water Regulaons

When choosing an installaon locaon, you

must ensure that clearances will be met and

that the vent length will be within required

limits. Consider the installaon

environment, water quality, and need for

freeze protecon. Requirements for the gas

line, water lines, electrical connecon, and

condensate disposal can be found in their

respecve installaon secons in this

manual.

This secon provides informaon on the

importance of water quality to the Rinnai

Condensing Boiler. The informaon is

intended to serve as general guidelines only

and is not a complete list of water quality

guidelines.

• Unsuitable heang system water can cause

the formaon of scale or sludge, which

aects system eciency. It can also cause

corrosion and reduce life of the heat

exchanger.

• Never use water that has been treated by a

reverse osmosis, deionized, or dislled

water to soen the water to ll the heang

system.

• For Domesc Hot Water systems, if you

install the boiler in an area that is known to

have hard water or that causes scale build-

up, the water must be treated and may

require a more frequent ushing schedule.

Scale build-up is caused by hard water and

can be accelerated if the boiler is set at a

high temperature. Rinnai oers

Southeastern Filtraon’s “ScaleCuer Water

Condioning System” that oers superior

lime scale prevenon and corrosion control

by feeding a blend of control compounds

into the cold water supply.

• Oxygen permeable or rubber tubing is not

permied in the heang system unless it is

separated from the boiler by a plate heat

exchanger.

• Thoroughly ush the system prior to lling.

While ushing, isolate the boiler.

• Do not introduce any system cleaner into

the boiler. Flush the system thoroughly to

remove all system cleaner before lling the

boiler with water.

• When freeze protecon of the heang

system is desired, only use Rinnai-approved

anfreezes. The allowed maximum

concentraon is 40%.

• Reference secon “14.1 Approved Cleaners,

Inhibitors and Anfreezes” in the Appendix

for an approved list of system cleaners,

inhibitors, and anfreezes.

IMPORTANT

Replacement of components due to

water quality damage is not covered by

the warranty.

Loading...

Loading...