Rinnai I-Series Condensing Boiler Combi Manual 15

DO NOT install the boiler in an area

where water leakage of the unit or

connecons will result in damage to

the area adjacent to the appliance

or to lower oors of the structure.

When such locaons cannot be

avoided, it is required that a

suitable drain pan, adequately

drained, be installed under the

boiler. The pan must not restrict

combuson air ow.

DO NOT install the boiler in an area

with negave air pressure.

DO NOT obstruct the ow of

combuson and venlaon air.

DO NOT use substute parts that

are not authorized for this boiler.

DO NOT install the boiler on

carpeng.

DO NOT

Gather the recommended tools and parts

before starng installaon.

Items Needed

• Pressure relief valve for domesc

hot water (150 PSI / 1,034 kPa)

• Pressure/Temperature Gauge

Note: When aaching the pressure/

temperature gauge, please comply

with applicable codes and the ASME

standard.

• Low loss header or closely spaced

tee

• Expansion tank for a closed heang

system

• Isolaon valve kit or equivalent

components (for quick isolaon of

the boiler for service and/or

maintenance)

• Air separator

• Standard tools for central heang,

gas ng, plumbing and electrical

wiring.

• Digital manometer capable of

reading both posive and negave

pressure

• Digital mulmeter capable of

reading microamps

• pH digital meter or test strips

• For wall mounng bracket

installaon:

− Level

− Screws (use appropriate screws

for type of wall construcon)

Other Items You May Need

• Combuson analyzer (intended for

use with condensing boilers)

• Hand truck with fastening belt

• Ensure the wall is of sucient

strength to support the weight of the

boiler, piping and any other

components needed for installaon;

if it is not, please reinforce the wall as

appropriate.

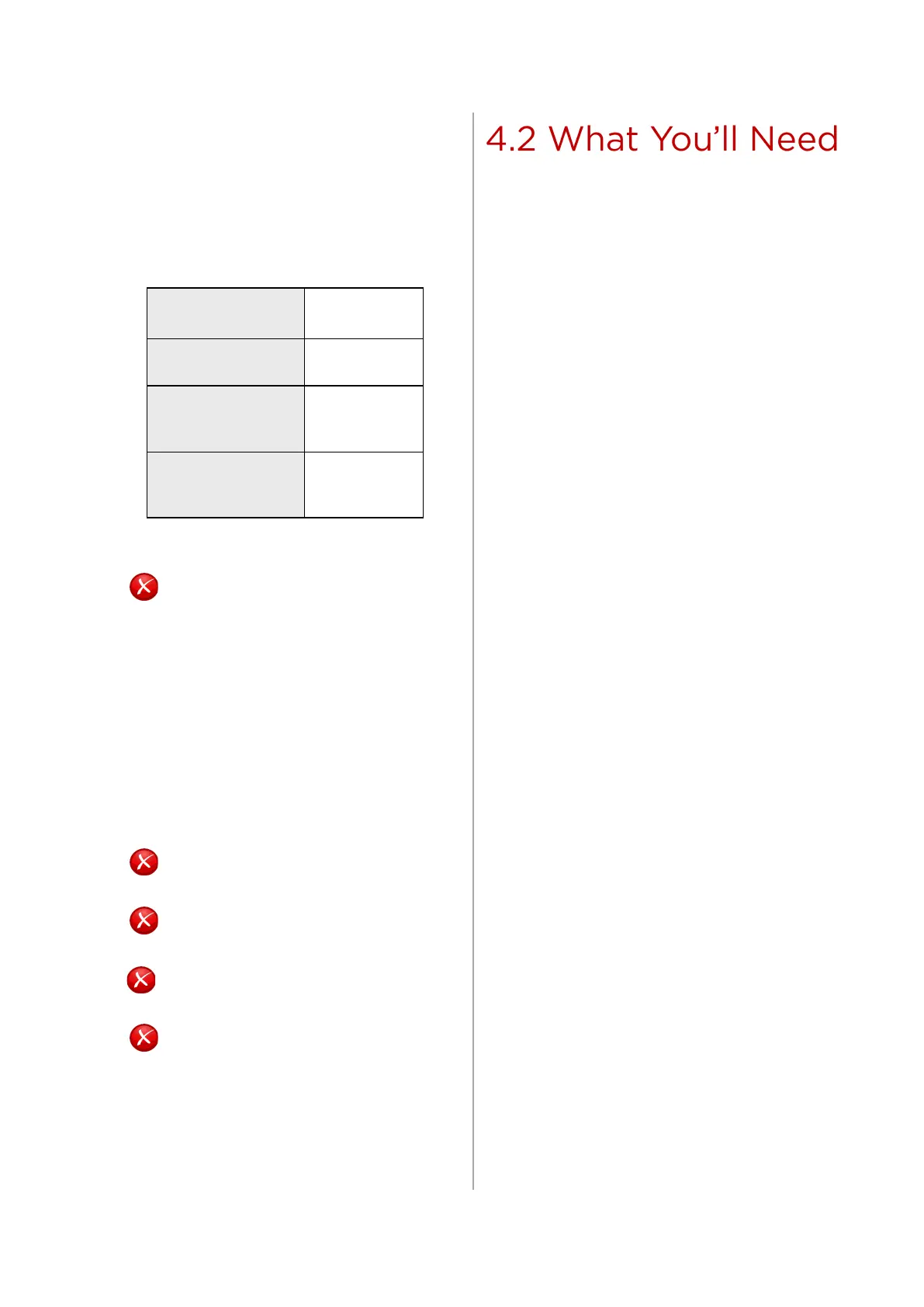

• Operang limits of the boiler:

Maximum boiler set

point temperature:

180°F (82 °C)

Maximum operang

pressure:

45 psi (3.1 bar)

Maximum allowable

working

temperature ASME:

210°F (99°C)

Maximum allowable

working pressure

ASME:

45 psi (3.1 bar)

Loading...

Loading...