32 / 44

5 OPERATION

5.1 Preliminary controls

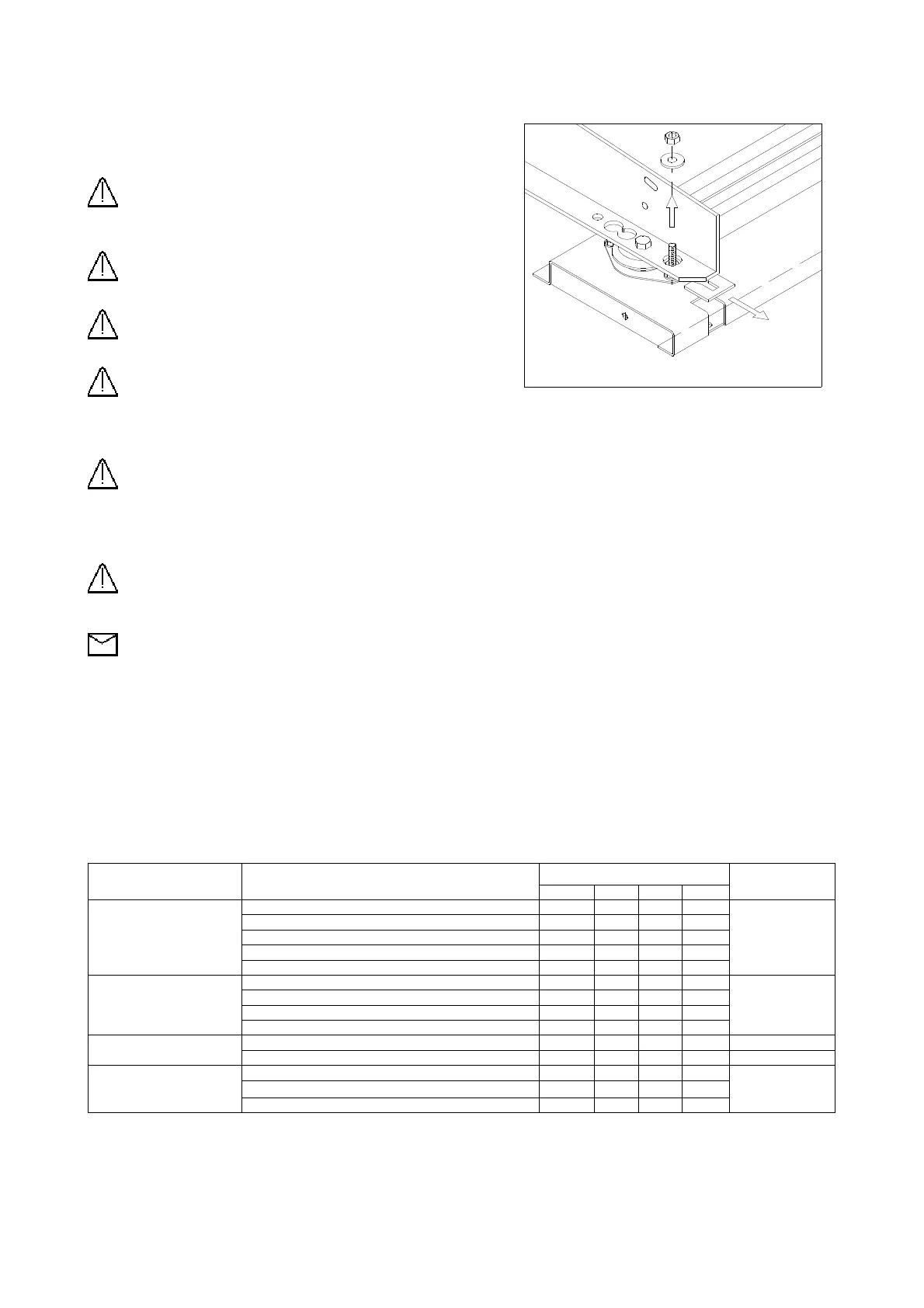

Remove the transport safety devices of the elastic feet (see Fig. 10)

and conserve them for future handling.

Warning

: Check the correspondence between the

process data and the ROBOX DV characteristic

indicated in the nameplate.

Warning : Check the correct position of the V-belt

and their correct tensioning (see paragrph 6.3)

Warning : Fill both blower sumps with lubricating

oil (par. 6.1), grease the motor bearings

Warning : Check the efficiency of safety devices.

Fig. 10

5.2 First start up

Warning : The personnel must wear the noise protection devices.

Open the shut-off valve on the discharge pipe or on the suction pipe.

Remove the front panel of noise hood and remove the V-belt (see paragraph 6.4)

Check the direction of rotation of the motor by means of a short current pulse, it must be counter clockwise viewed from the shaft.

Warning : Do not rotate the blower in the wrong direction for more than a few revolutions.

Reinstall the V-belts (see paragraph 6.4) and remove the motor transport safety device

Nota : Conserve the motor safty transoprt device for the following service operations (see par. 6.4)

Check the direction of rotation of the fan, it must be counterclockwise seen from the motor.

Open the valve of the cooling circuit (only for -RF)

Start-up ROBOX DV.

Check the operation of the relief valve (see paragraph 5.5)

Increase the operating pressure gradually until the rated value is reached.

During the first 8 hours of operation check that there are no strange noises, vibrations, oil leakage or overheating, if such problems are found

stop ROBOX DV immediately and contact ROBUSCHI or an authorized distributor.

5.3 Operation

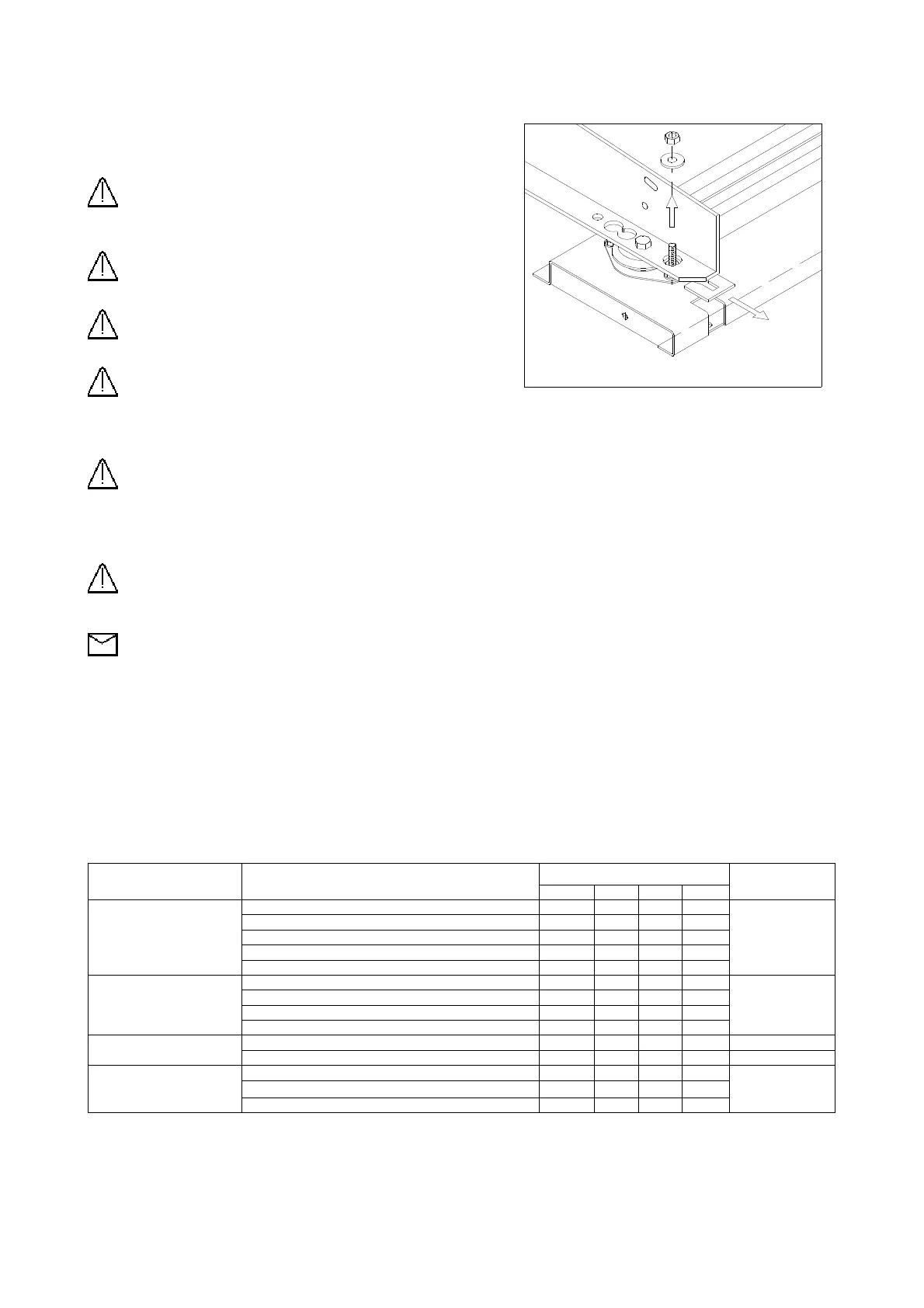

CHECK PARAMETER

FREQUENCY

NOTE

h G S M

VISUAL

Pressure 1

ROBOX DV

In

operation

Temperature 1

Absorbed power 1

Cooling liquid flow 1

Noise 1

LUBRIFICATION

Oil level 500

ROBOX DV

out of operation

Oil Leakage 1

Viscosity 500

Oil change 4000 6

FILTER

Vacuum 1 < 35 mbar

Clogging 2 > 60 mbar

TRANSMISSION

Wear 2000

ROBOX DV

out of operation

Belt tension 2000

Belt change 15000 24

h operation hours S weeks

G days M months

Note : in case of double indication follow the most limiting one for the application

Loading...

Loading...