144 Rockwell Automation Publication 2198-UM001D-EN-P - May 2014

Chapter 7 Troubleshooting the Kinetix 5500 Drive System

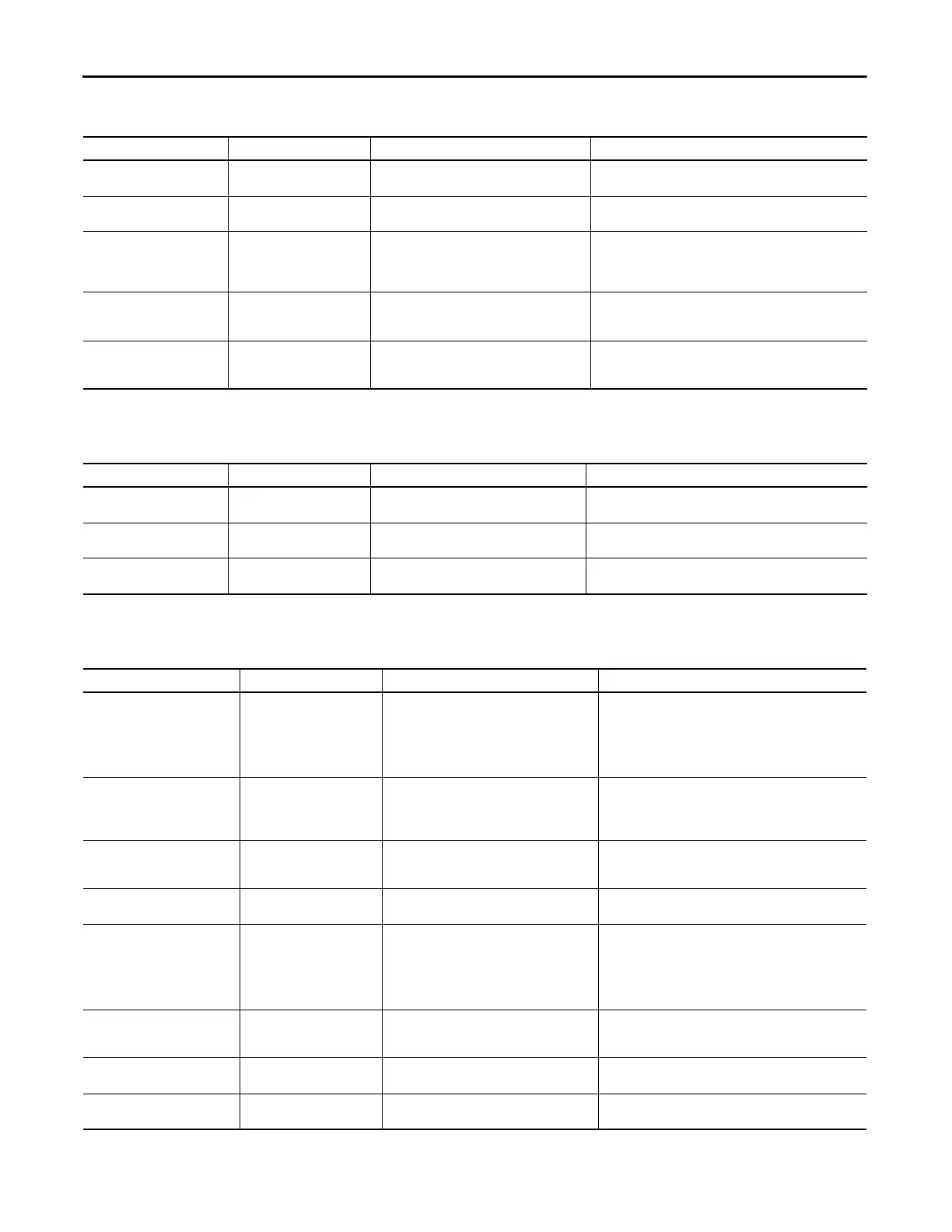

Table 58 - INIT FLT Fault Codes

Exception Code on Display Exception Text Problem Possible Solutions

INIT FLT M01 – ENCODER DATA Smart Encoder Data Corruption The data stored in the encoder has a checksum error.

•Cycle control power

• Return motor for repair if fault continues

INIT FLT M02 – MTR DATA RANGE Motor Data Range Error

A motor data attribute stored in the encoder is out of

range.

•Cycle control power

• Return motor for repair if fault continues

INIT FLT M03 – MTR ENC STARTUP

Motor Feedback Communication

Startup

Communication with the encoder could not be

established.

•Cycle control power

• Check motor feedback connector

• Check motor power and feedback shield terminations on the drive

• Return motor for repair if fault continues

INIT FLT M14 – SAFETY FIRMWARE Safety Firmware

The loaded Safety firmware is not compatible with the

drive firmware.

•Cycle control power

• Update the drive firmware

• Return drive for repair if fault continues

INIT FLT M20 – UNKNOWN

MODULE

Unknown Module The product code of the power board is invalid.

•Cycle control power

• Reset the drive

• Return drive for repair if fault continues

Table 59 - INHIBIT Fault Codes

Exception Code on Display Exception Text Problem Possible Solutions

INHIBIT S02 – MOTOR NOT

CONFIGURED

Motor Not Configured The motor has not been properly configured for use. Verify motor configuration in the Logix Designer application.

INHIBIT S03 – FEEDBACK NOT

CONFIGURED

Feedback Not Configured

The feedback has not been properly configured for

use.

Verify feedback configuration in the Logix Designer application.

INHIBIT M05 – SAFE TORQUE OFF Start Inhibit – Safe Torque Off The safety function has disabled the power structure.

• Check safety input wiring

•Check state of safety devices

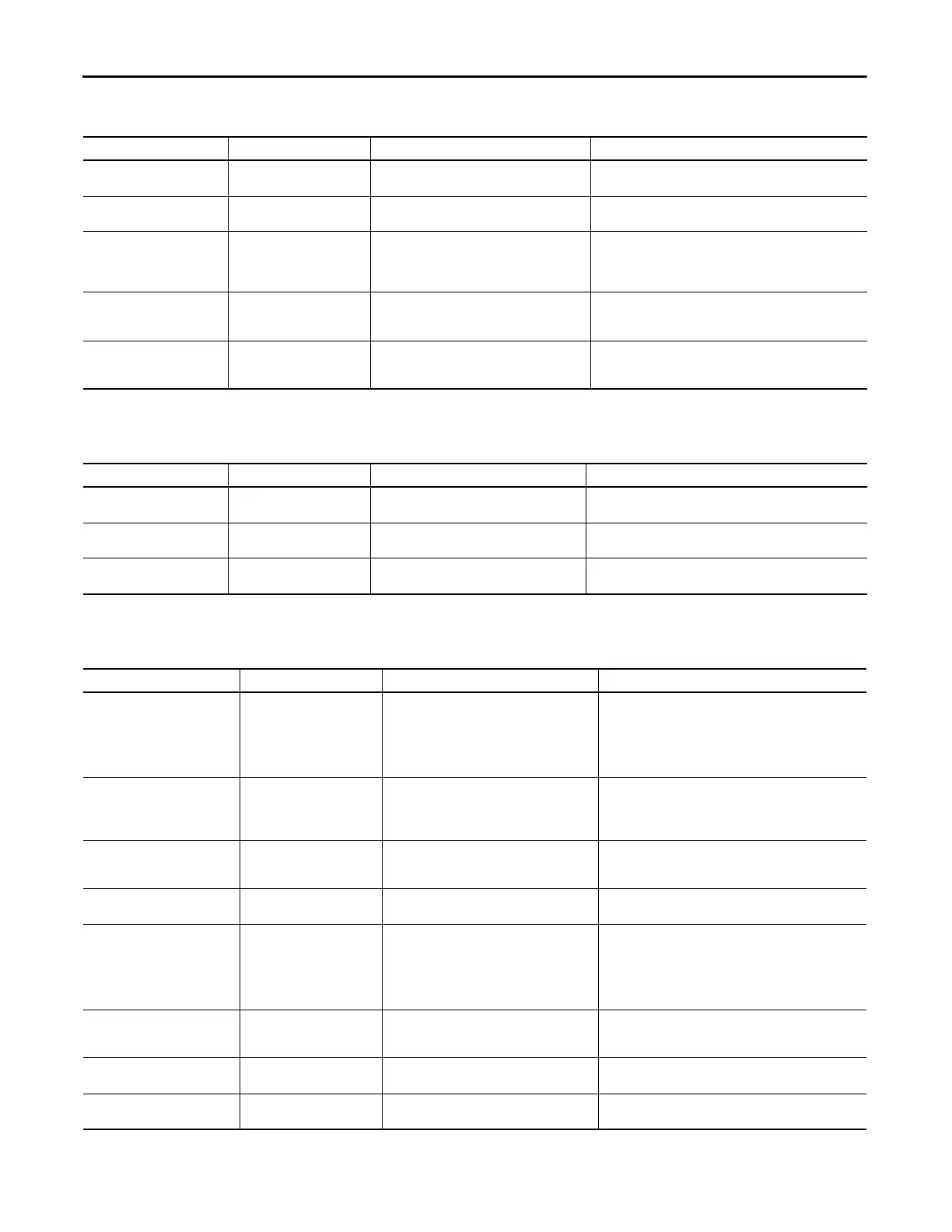

Table 60 - NODE FLT Fault Codes

Exception Code on Display Exception Text Problem Possible Solutions

NODE FLT 01 – LATE CTRL UPDATE Control Connection Update Fault

Several consecutive updates from the controller have

been lost.

• Remove unnecessary network devices from the motion network

• Change network topology so that fewer devices share common

paths

• Use high performance network equipment

• Use shielded cables

• Separate signal wiring from power wiring

NODE FLT 02 – PROC WATCHDOG nn Processor Watchdog Fault

The processor on the power board or control board

failed to update in a certain amount of time.

The nn sub-codes 00…06 are internal and result in

the same possible solution.

• Cycle control power

• Update the drive firmware

• Return drive for repair if fault continues

NODE FLT 03 – HARDWARE 00 Hardware Fault -PwrIF

Communication with the power board could not be

established.

• Cycle control power

• Update the drive firmware

• Return drive for repair if fault continues

NODE FLT 03 – HARDWARE 01 Hardware Fault - Power Board DSP chip on the power board failure.

• Cycle control power

• Return motor for repair if fault continues

NODE FLT 03 – HARDWARE 02 Hardware Fault - DSL

Communication with the encoder could not be

established.

• DSL feedback wiring is incorrect (check against wiring diagram)

• DSL feedback wiring is shorted or open

• DSL feedback cable is defective

• Kinetix VP motor feedback device is defective

•Cycle power

• Return drive for repair if fault continues

NODE FLT 03 – HARDWARE 03 DSL Internal Hardware Fault

A DSL hardware error internal to the drive was

detected.

• Check DSL feedback device, wiring, and cable

•Cycle power

• Return drive for repair if fault continues

NODE FLT 03 – HARDWARE 04

Hardware Fault - Board

Compatibility

The control and power boards are incompatible. Return drive for repair if fault continues

NODE FLT 05 – CLOCK SKEW FLT Clock Skew Fault

The controller time and the drive's system time are

not the same.

• Cycle control power

• Check controller and Ethernet switch operation

Loading...

Loading...