7-4 Rosco Maximizer 2B Asphalt Distributor

Maintenance

Fluids And Lubricants

Asphalt Pump Lubrication

Use only Rosco high-temperature, Teon impregnated

grease (part # 33384) at all times. Any other grease will

be liqueed in the high operating temperature and will

run out of the bearings. With no lubrication, the bearings

will seize in a short time.

Use only a hand held grease gun for all greasing. Wipe

grease ttings with clean cloth before greasing, to

avoid injecting dirt and grit. Replace and repair broken

grease ttings immediately. If a tting will not take

grease, remove and clean thoroughly. Clean lubricant

passageway.

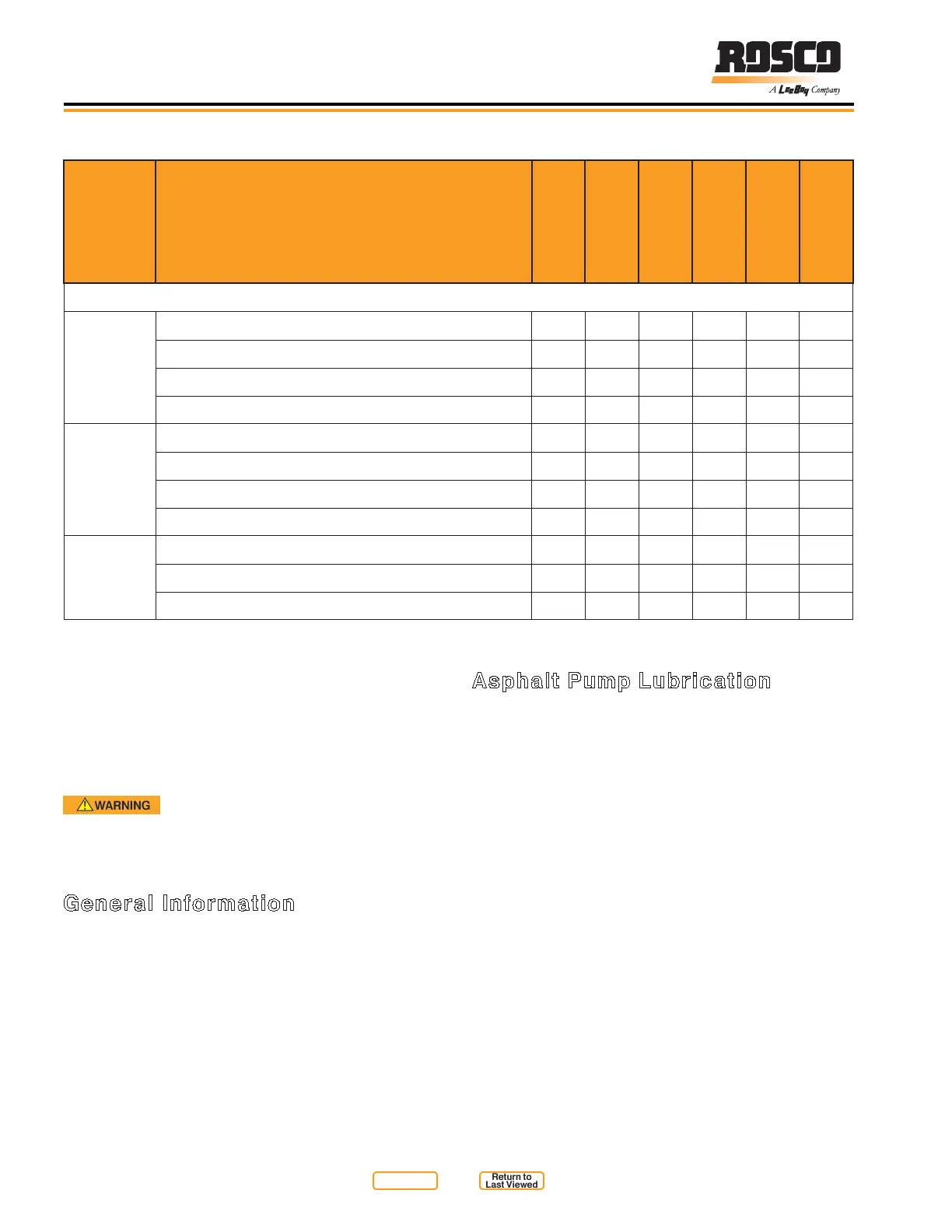

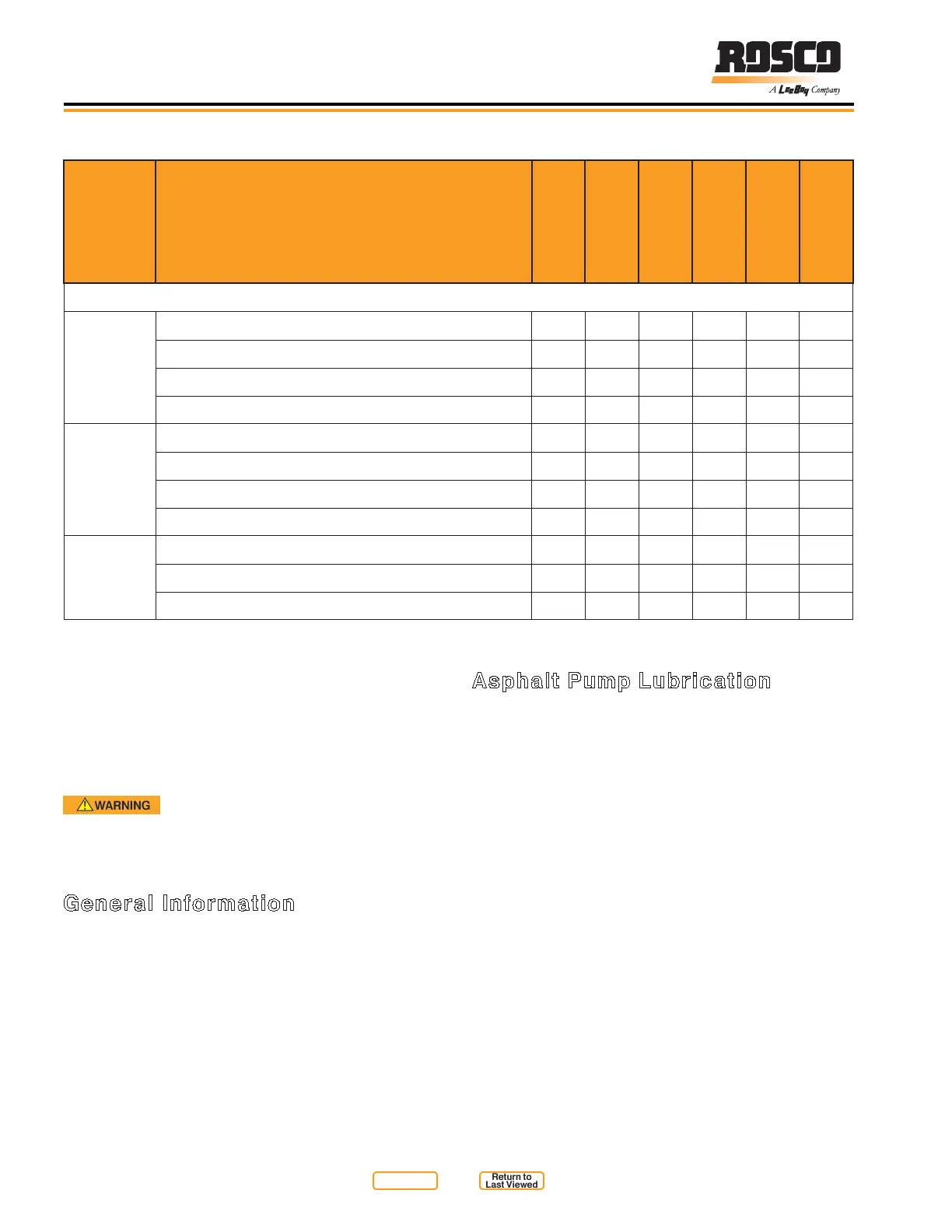

SYSTEM ITEM

3 Hours

Twice Daily

8 Hours

Daily

20 Hours

Weekly

80 Hours

Monthly

250 Hours

Semi-annually

400 Hours

Annually

C = Check, CL = Clean, L = Lubricate, R = Replace, T = Tighten

Spraybar

Hydraulic Cylinders CL

Nozzles, adjust alignment if necessary C

Hardware, tighten if necessary C

Spraybar, Extension & Pivot Point Gaskets & Washers R

Truck

Truck, service per Truck Operator’s Manual C

Wash Machine CL

Radar Horn Face Cover CL

Air System C

Engine

Coolant Level C

Engine Oil Level C

Fuel Level C

General Information

This section gives the necessary procedures for routine

and general maintenance on the Rosco Maximizer 2B

Asphalt Distributor.

NOTE: By following a careful service and maintenance

program for your Asphalt Distributor, you will

insure many years of trouble free operation.

Follow all safety precautions in this

manual.

Routine Maintenance

General Information

Maintenance must be a planned program that

includes periodic machine inspection and lubrication

procedures, (Table 7-1. Maintenance Intervals Chart).

The maintenance program must be done based on

the machine’s “Operating Hours” recorded on the

hourmeter, or on a “Periodic Schedule” which is done at

daily, weekly, monthly or yearly intervals.

Table 7-1. Maintenance Intervals Chart (continued)

Return to

Last Viewed

Return to

Thumb Index

Loading...

Loading...