6

Rosco Maximizer 2B Asphalt Distributor 6-9

Operation

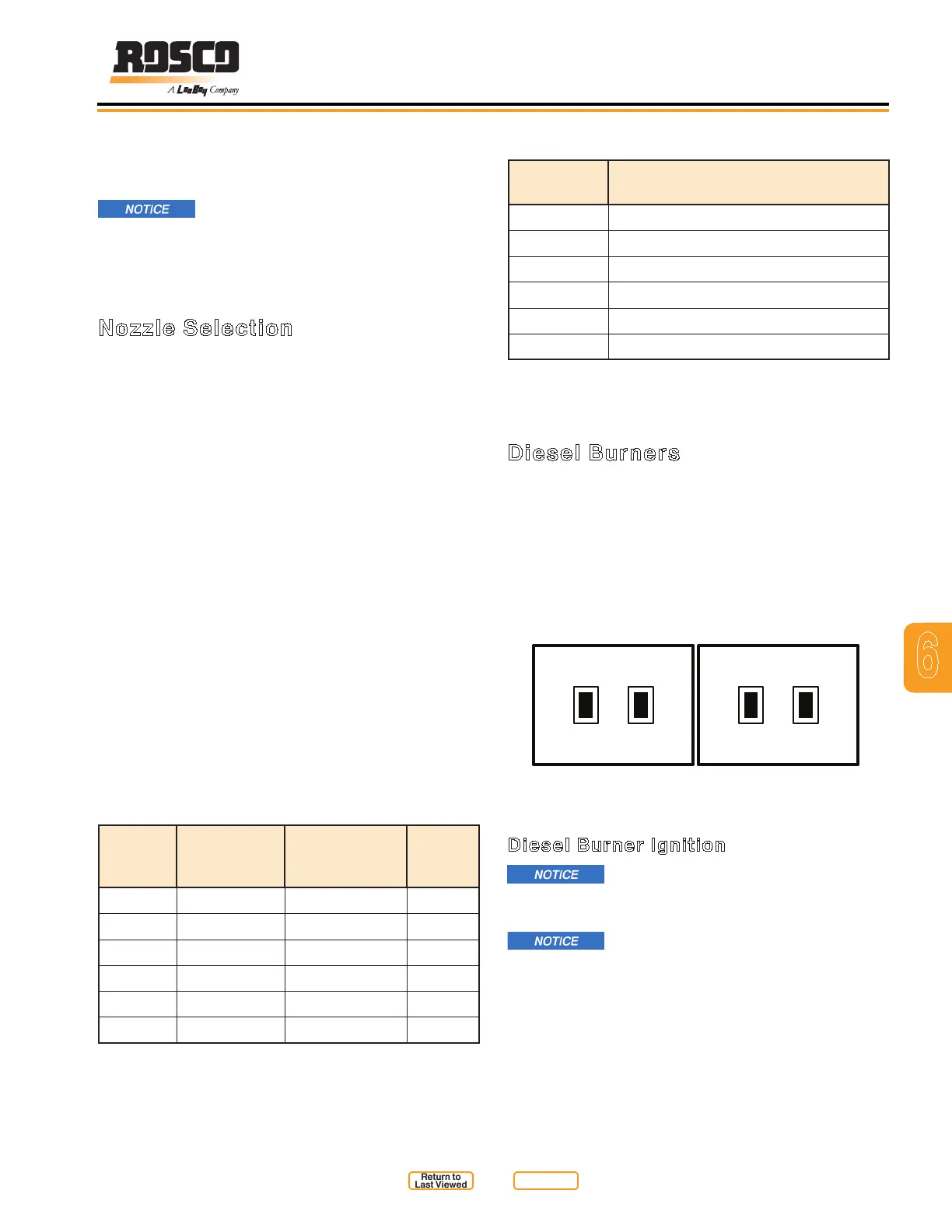

Table 6-2. Nozzle Size to Application Rate

NOZZLE

SIZE

APPLICATION RATE (GPM)

00

Extremely Light (1.5)

0 Light (4.0)

1 General (5.0)

1.5 Intermediate w/ certain emulsions (6.0)

2 Heavy (10.0)

3 Extra Heavy (15.0)

Burners & Torch

Operation

Diesel Burners

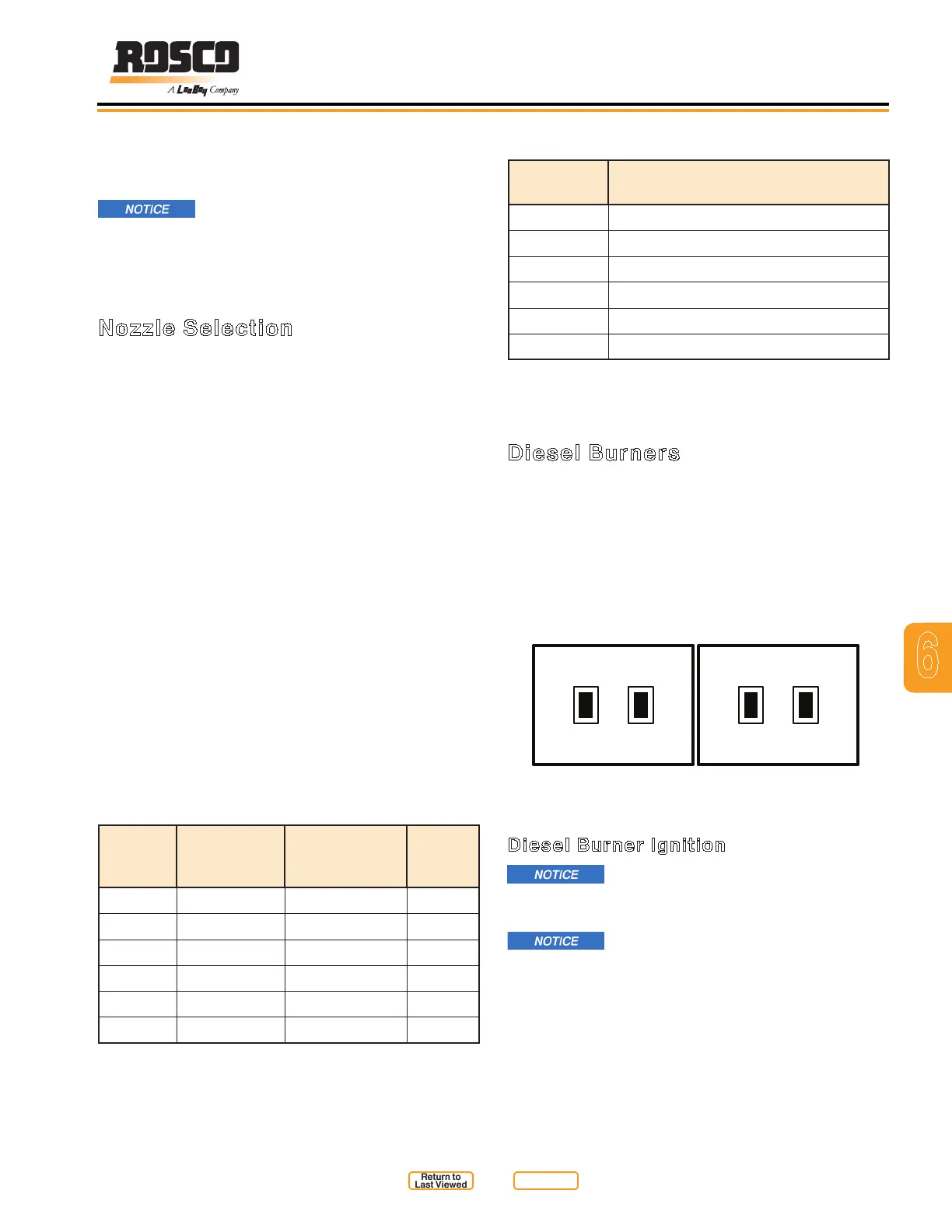

Control switches for the electronic ignited diesel

burners are mounted on the driver side rear fender,

(Figure 6-6).

1. Fuel Switch: Activates burner fuel solenoid and

ignites burner. Turn off to extinguish burner.

2. Blower Switch: Activates blower and fuel pump.

UPPER BURNER

FUEL BLOWER

READ SAFETY INSTRUCTIONS

PRIOR TO USE

READ SAFETY INSTRUCTIONS

PRIOR TO USE

FUEL BLOWER

LOWER BURNER

Fender Diesel Burner Switches

Figure 6-6

Diesel Burner Ignition

Before heating asphalt material, refer

to Systems Overview, Burner System, earlier in this

section for further information and precautions.

Run the burners for short periods

of time (15 minutes ON, 15 minutes OFF) to allow

the heat to dissipate through the material. This will

prevent damage to the ue liner.

NOTE: The valve on top of each cylinder must be placed

in the proper direction for correct function of the

spray system.

Always check the function of the valve

after servicing and before starting a job. Be sure

there is a proper connection and no leakage.

For a further breakdown of the spraybar valve assembly,

(see Illustrated Parts List (IPL) in Section 10).

Nozzle Selection

The correct nozzle selection depends on:

1. the application rate setting

2. the truck speed

3. the type of material being sprayed.

The standard Rosco nozzle size is a NO. 1. However,

other factors will determine efciency and the quality

of the spray pattern. Exceeding nozzle maximum ow

rate may cause fogging and inconsistent application

rates. Using a nozzle that is too large will cause a poor

spray pattern, (Table 6-1. Nozzle Size to Flow Rate and

Table 6-2. Nozzle Size to Application Rate).

The recommended nozzle angle is 20° and is set

to that specication at the factory. After changing

nozzles, or when adjustments need to be made, use

the Nozzle Alignment Wrench (Leeboy #8695) and the

Valve Alignment Tool (Leeboy #18981) for accurate

positioning. Tools are provided with each unit, (Figure

6-4).

NOTE: For additional information about nozzle selection

and adjustment, see applicable troubleshooting

topics (see Maintenance in Section 7).

Table 6-1. Nozzle Size to Flow Rate

NOZZLE

SIZE

RECOMM-

ENDED

FLOW - GPM

APPLICATION

RATE - GAL /

SQ. YD.

ROSCO

PN

00 1.2 .03 - .08 35565

0

3.0 .05 - .20 32917

1

4.0 .10 - .30 32918

1.5 6.0 .15 - .40 36299

2

8.5 .25 - .55 32919

3

13.5 .35 - 1.00 32920

Return to

Last Viewed

Return to

Thumb Index

Loading...

Loading...