4

Rosco Maximizer 2B Asphalt Distributor 4-9

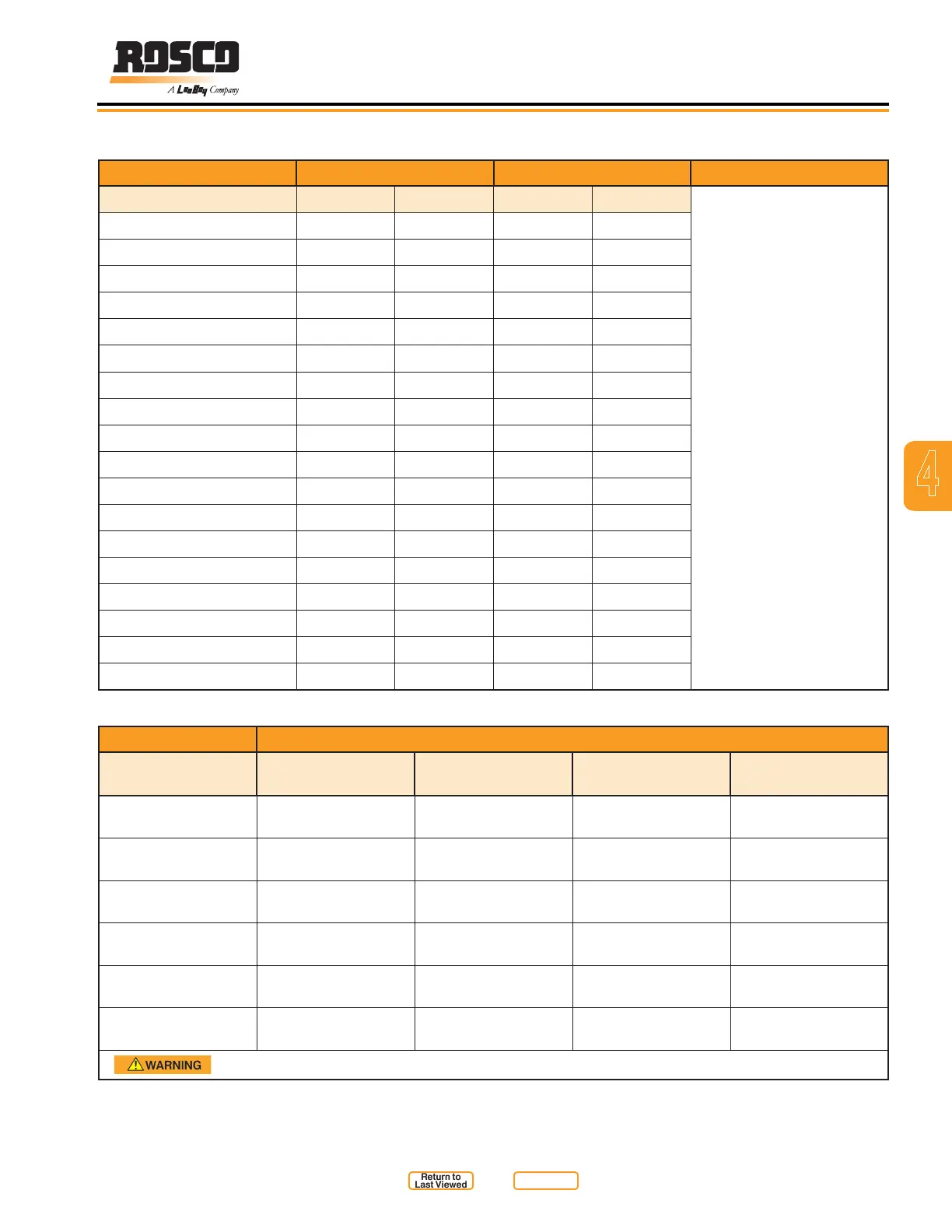

Specications

TYPE & GRADE SPRAY TEMP STORE TEMP MIN FLASH POINT

Emulsied Asphalts °C °F °C °F

RS-1 20 - 60 70 - 140 20 - 60 70 - 140

RS-2 50 - 85 125 - 185 50 - 85 125 - 185

HFRS-2 50 - 85 125 - 185 50 - 85 125 - 185

MS-1 20 - 70 70 - 160 10 - 60 50 - 140

MS-2 20 - 70 70 - 160 50 - 85 125 - 185

MS-2h 20 - 70 70 - 160 50 - 85 125 - 185

HFMS-1 20 - 70 70 - 160 10 - 60 50 - 140

HFMS-2 20 - 70 70 - 160 50 - 85 125 - 185

HFMS-2h 20 - 70 70 - 160 50 - 85 125 - 185

HFMS-2s 20 - 70 70 - 160 50 - 85 125 - 185

SS-1 20 - 70 70 - 160 10 - 60 50 - 140

SS-1h 20 - 70 70 - 160 10 - 60 50 - 140

CRS-1 50 - 85 125 - 185 50 - 85 125 - 185

CRS-2 50 - 85 125 - 185 50 - 85 125 - 185

CMS-2 20 - 70 70 - 160 50 - 85 125 - 185

CMS-2h 20 - 70 70 - 160 50 - 85 125 - 185

CSS-1 20 - 70 70 - 160 10 - 60 50 - 140

CSS-1h 20 - 70 70 - 160 10 - 60 50 - 140

Table 4-5. Guide For Loading Asphalt Products

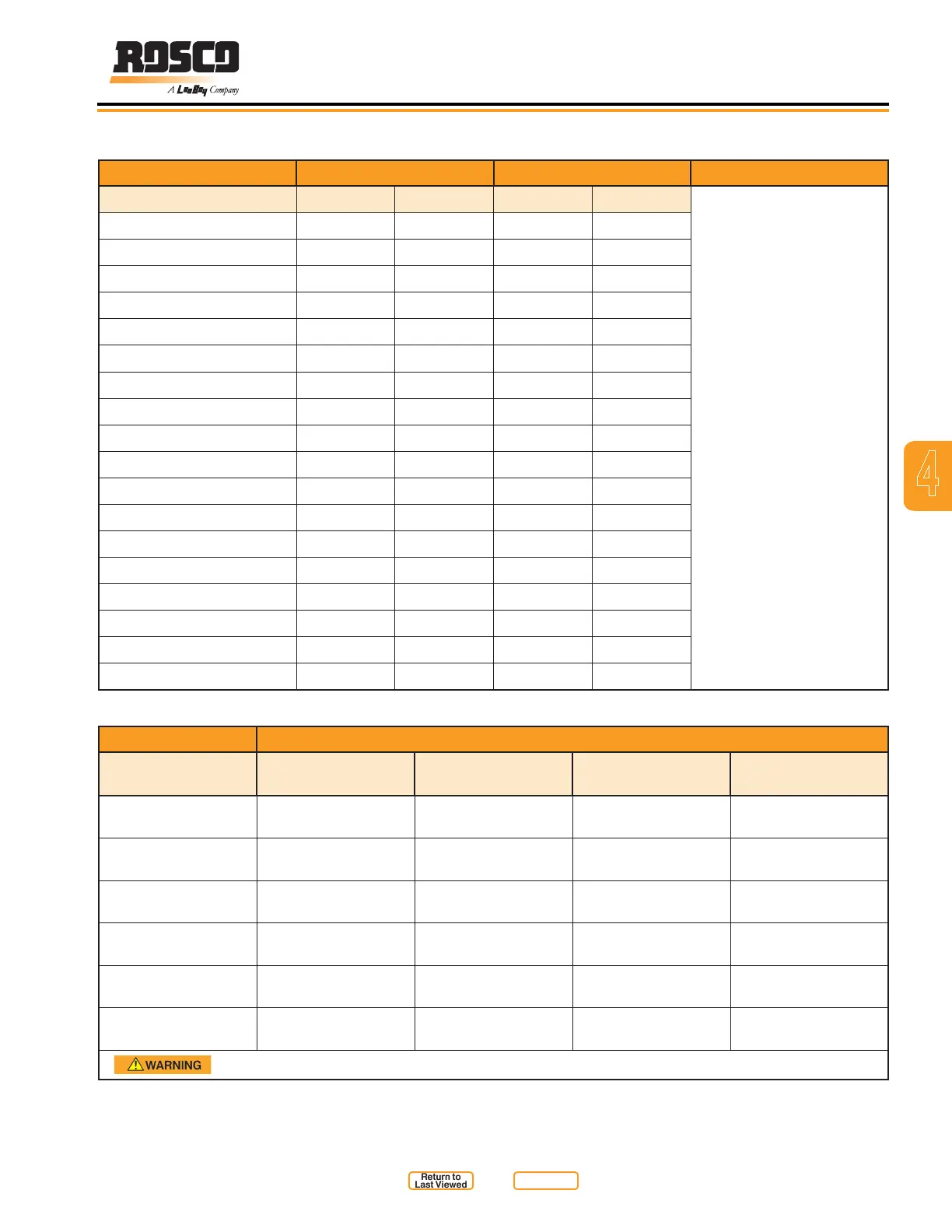

PRODUCT TO BE LOADED

LAST PRODUCT IN

TANK

ASPHALT CEMENT

CUTBACK

ASPHALT

CATIONIC

EMULSION

ANIONIC

EMULSION

Asphalt Cement OK to load Ok to load Empty to no

measurable quantity

Empty to no

measurable quantity

Cutaback Cement * Empty Tank Ok to load Empty to no

measurable quantity

Empty to no

measurable quantity

Cationic Emulsion * Empty Tank Empty to no

measurable quantity

Ok to load Empty to no

measurable quantity

Anionic Emulsion * Empty Tank Empty to no

measurable quantity

Empty to no

measurable quantity

Ok to load

Crude Petroleum and

Residual Fuel Oils

* Empty Tank Empty to no

measurable quantity

Empty to no

measurable quantity

Empty to no

measurable quantity

Any Product not

listed above

Tank must be

cleaned

Tank must be

cleaned

Tank must be

cleaned

Tank must be

cleaned

*

Any material remaining in tank will produce dangerous conditions.

Table 4-4. Guideline Temperatures For Liquid Asphalts (continued)

Return to

Last Viewed

Return to

Thumb Index

Loading...

Loading...