4

Rosco Maximizer 2B Asphalt Distributor 4-15

Specications

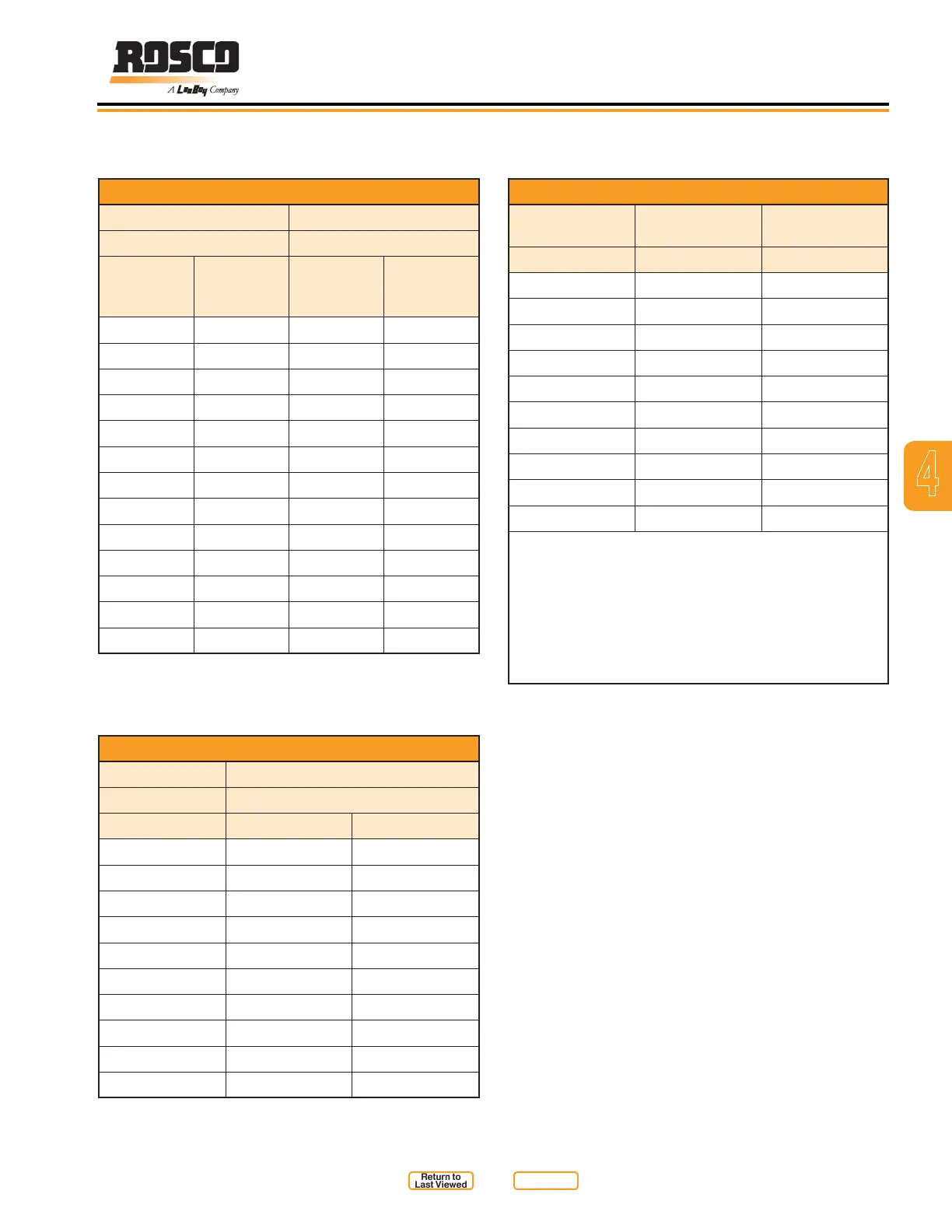

Table 4-15. Flats Method Values For Selected

Terminations

Flats Method Values

Termination

Type

Dash Size Flats

1/16 Inch

JIC 4

1.5 - 1.75

JIC 6 1.0 - 1.5

JIC 8 1.5 - 1.75

JIC 10 1.0 - 1.5

JIC 12 1.0 - 1.5

JIC 16 .75 - 1.0

JIC 20 .75 - 1.0

JIC 24 .75 - 1.0

JIC 32 .75 - 1.0

JIS 4 .5 - 1.5

1. Seal faces must be in contact and the tting fully

hand tightened before marking ats.

2. Flats method is most accurate for the rst

assembly cycle, for multiple disassembly/

assembly cycles torque values are more reliable.

3. Tightening 2 ats or more is analogous to severe

over torque and may damage seal faces.

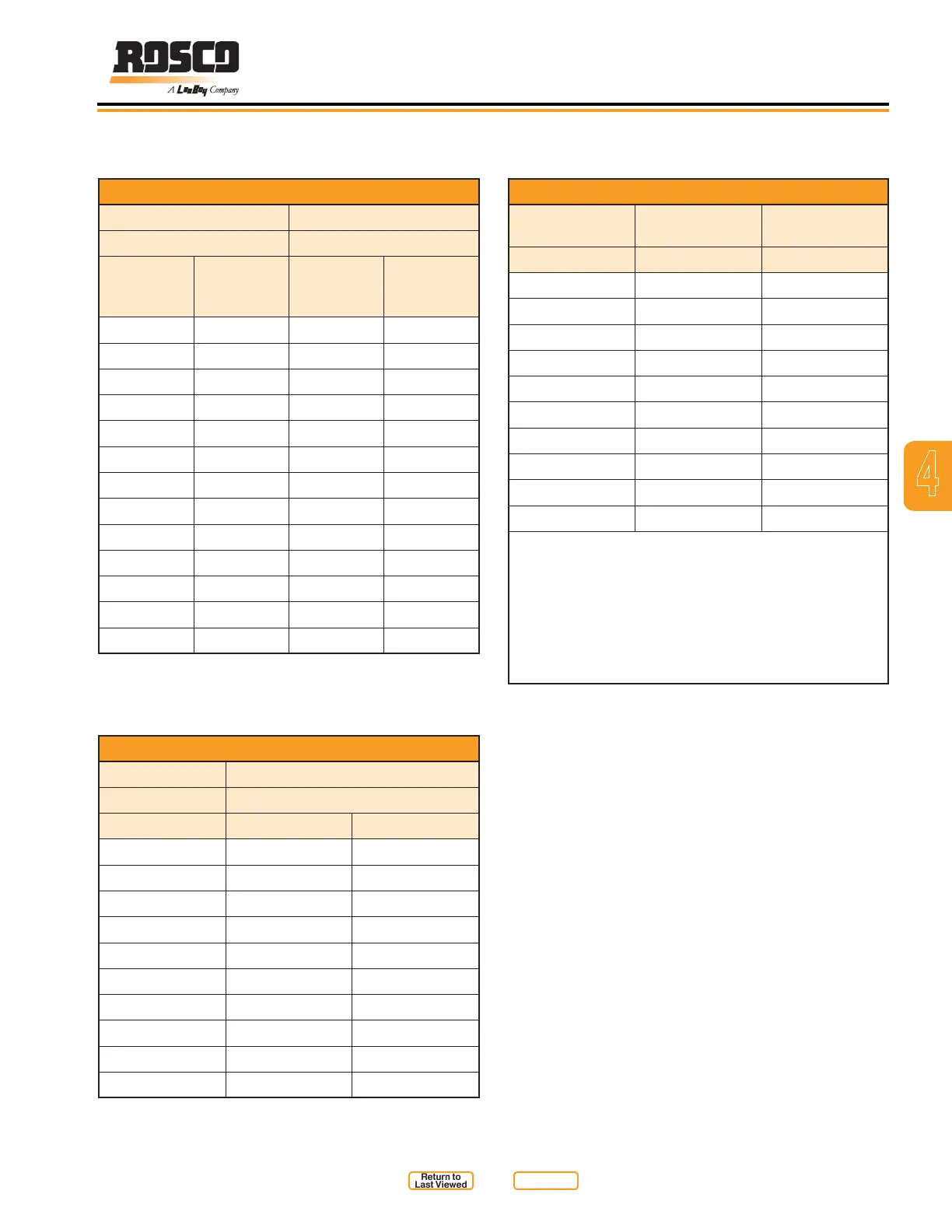

Table 4-13. Torque Specications For DIN 24, DIN

60, and Inverted Cone Style Coupling Terminations

DIN 24, DIN 60, and Inverted Cone

Size Torque

mm ft-Lb

Light Series

Tube OD

Heavy

Series

Tube OD

Min Max

6 7 15

8 15 26

10 8 18 30

12 10 22 33

14 12 26 37

15 14 30 52

16 30 52

18 20 44 74

22 25 59 89

28 30 74 111

38 74 162

35 133 184

42 148 221

Table 4-14. Torque Specications For BSP 30°

Inverted Cone and JIS Coupling Terminations

BSP 30° Inverted Cone and JIS

Dash Size Torque

mm ft-Lb

1/16 Inch Min Max

-2 7 9

-4 11 18

-6 19 28

-8 30 36

-10 37 44

-12 50 60

-16 79 95

-20 127 152

-24 167 190

-32 262 314

Return to

Last Viewed

Return to

Thumb Index

Loading...

Loading...