24

FA ROTEX Solaris RPS4 - 06/2015

6 x Control

6.2.9 Speed regulation of the solar operating

pump P

S

After reaching the switch-on conditions, the SOlaris R4 controller

leaves:

– the actuation of the solar operating pump P

S

at full output for

filling the solar system. This takes place dependent on the set

parameter value "Time P2" in [secs].

Î If the correctly adjusted FlowSensor detects a steady flow

before this time has expired, the solar system is com-

pletely filled with water.

– the actuation of the solar operating pump P

S

at full output up

to possible maximum flow rate of the system.

– the stepless output reduction of the solar operating pump P

S

,

until the calculated target spread "DT" maintains the set value

in accordance with fig. 6-2, or until the flow rate falls below the

minimum flow rate V2 (fig. 6-3 and tab. 6-1).

– the stepless increase in output of the solar operating pump P

S

after a safety period "t

2

" (fig. 6-3).

If the pump output is too low, the flow in the solar circuit can col-

lapse as a result of system and temperature influences. If the flow

rate falls below the value "V2" (fig. 6-3 and tab. 6-1), the con-

troller detects a flow rate breakaway, the last valid output stage

is saved as the minimum pump output value. Lower pump output

stages are automatically blocked.

The temperature-dependent output regulation of the solar oper-

ating pump P

S

then takes place between the determined

minimum and maximum outputs. The spread of "T

V

" and "T

R

"

(=T

V

– T

R

) is measured continuously and compared with the

target spread "DT". If the temperature spread between "T

V

" and

"T

R

" is too great, the pump output (max. 10 stages) and thus also

the flow rate through the solar panel is increased until the target

spread is achieved. If the spread is too small, the pump output is

reduced (fig. 6-2). The current pump output is displayed during its

active running time in the operating display "Throughput", next to

the throughput measured value in percent. A typical operating se-

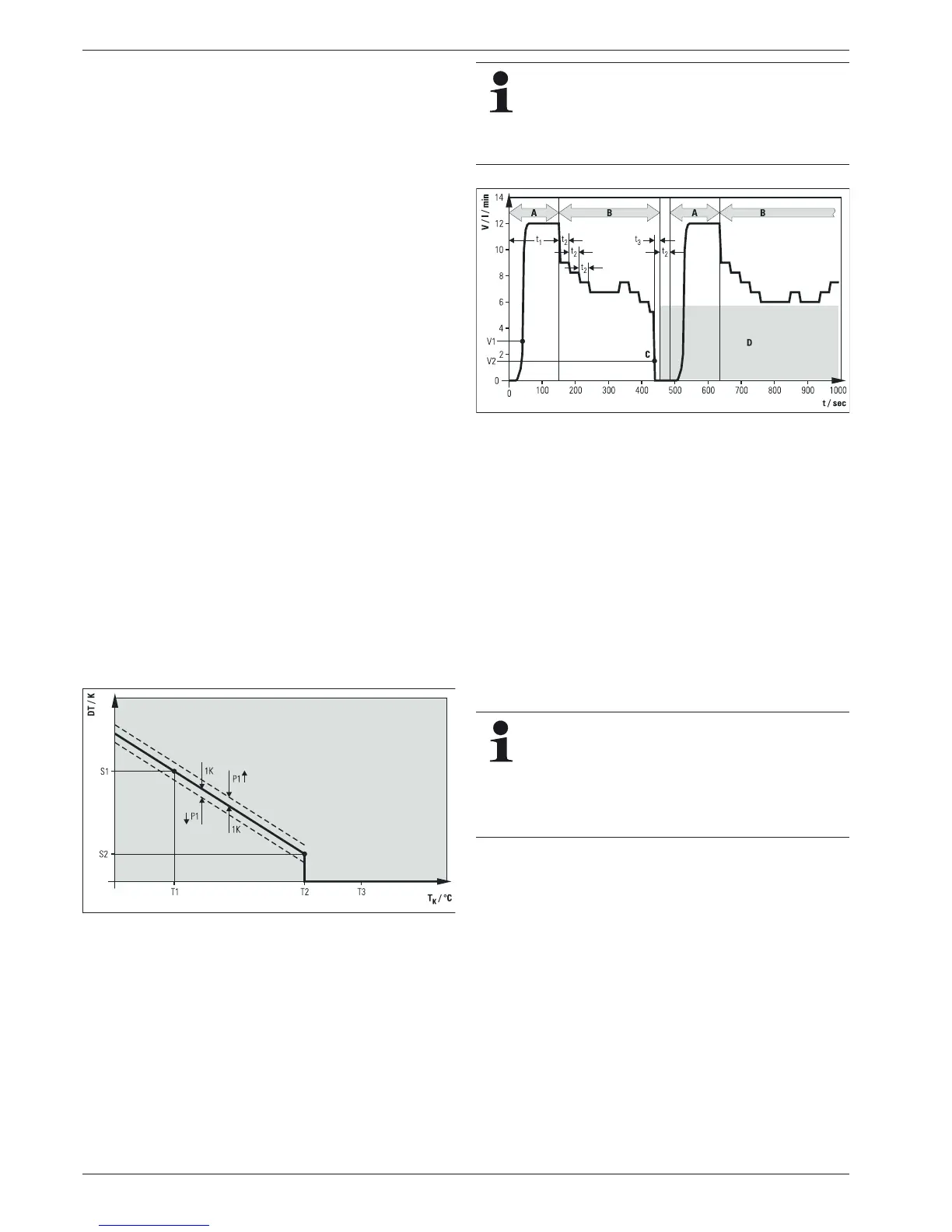

quence of a modulating solar system is shown in fig. 6-3.

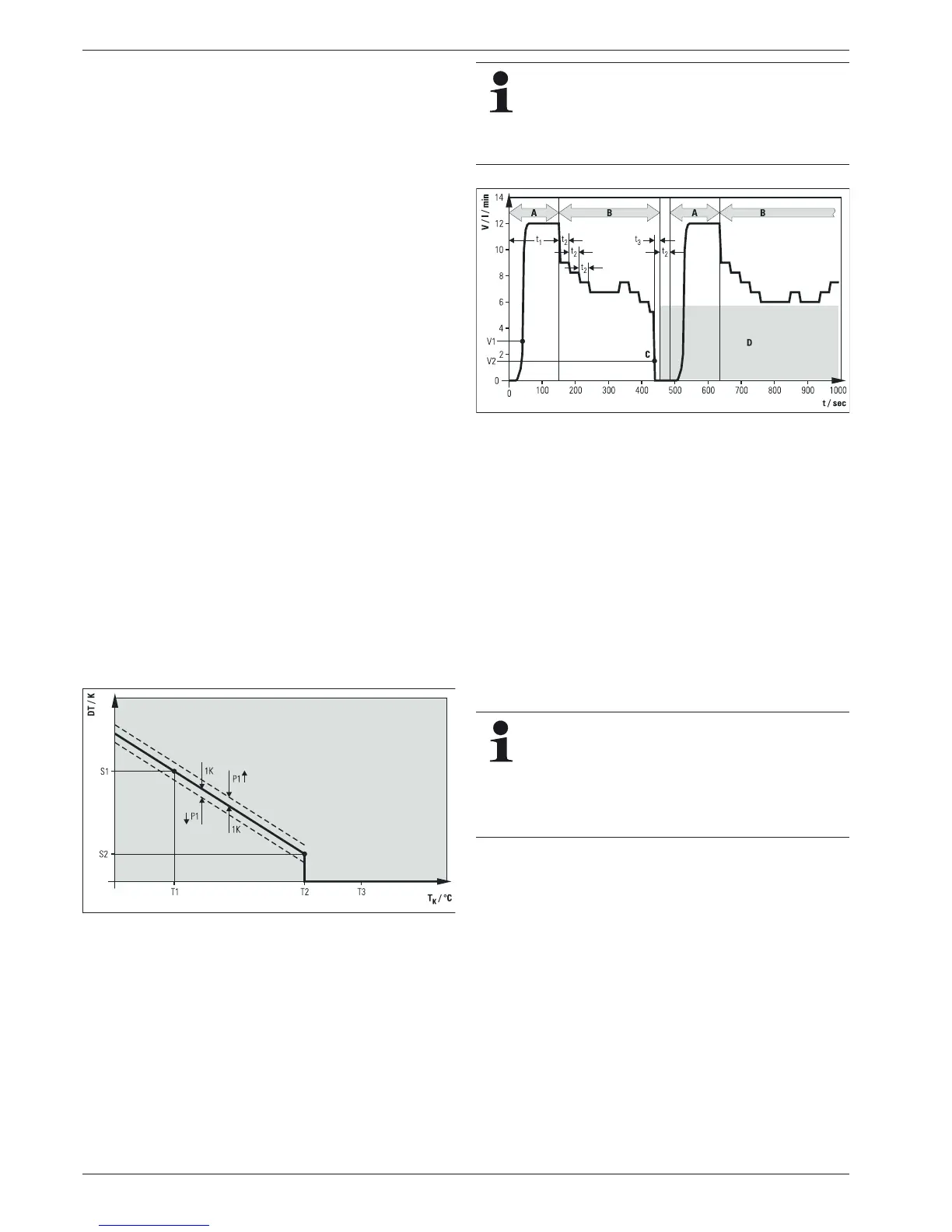

Fig. 6-2 Pump output control as a function of temperature difference

Fig. 6-3 Example for modulation operation with flow-caused block of

low pump stages on systems with FlowSensor

6.2.10 Total Reset Function

The device reacts to a total reset with a new start (self-test), all

parameters are reset to the factory settings and then all the

blocked pump output stages are released. The reset takes place:

Ɣ Via menu path: Activation by heating expert in the "System"

setting menu.

Ɣ By quick access: Simultaneous pushing of the OK and arrow

keys.

DT Target spread (calculated for the operating point)

P

S

Solar operating pump

S1 Top target spread ("Spread 1")

S2 Bottom target spread ("Spread 2")

T

K

Collector temperature

T1 Frost protection temperature ("T frost")

T2 Booster temperature ("T

K

max")

T3 Restart protection temperature ("T

K

perm")

— Target spread

- - Switching limits for pump modulation

n Pump output is increased

p Pump output is reduced

Controller is switched off and back on again:

– automatically blocked pump stages are released

again.

– the system is automatically regulated again.

– manually blocked pump stages (see chapter 6.3.8)

remain blocked.

A Start phase

B Operating phase (modulation)

C Interrupted flow

D Low pump output stages are automatically blocked after a flow

breakaway

P

S

Solar operating pump

t Time

t

1

Minimum running time of solar operating pump P

S

at maximum

output ("Time P2")

t

2

Stabilisation time

t

3

Interruption detection period (10 s)

V Solar circuit flow

V1 Minimal flow rate in the start phase

V2 Minimal flow rate in the operating phase

A total reset deletes all individual settings and the event

memory is deleted. All calculated values (info parame-

ters) are set to zero.

If this total reset function is triggered via the menu path,

the total thermal yield remains. This value is also

deleted using the quick access via the button combina-

tions.

Loading...

Loading...