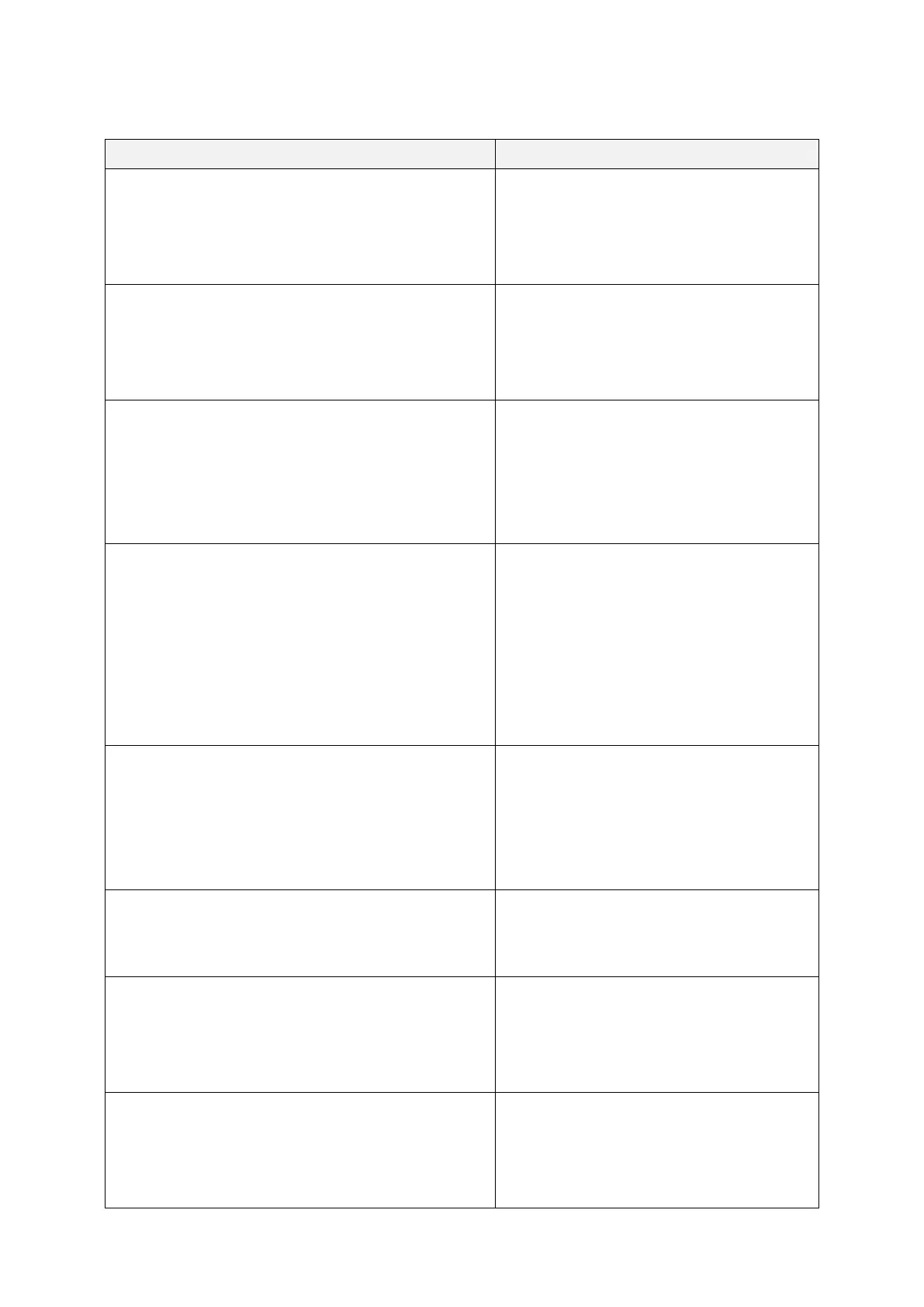

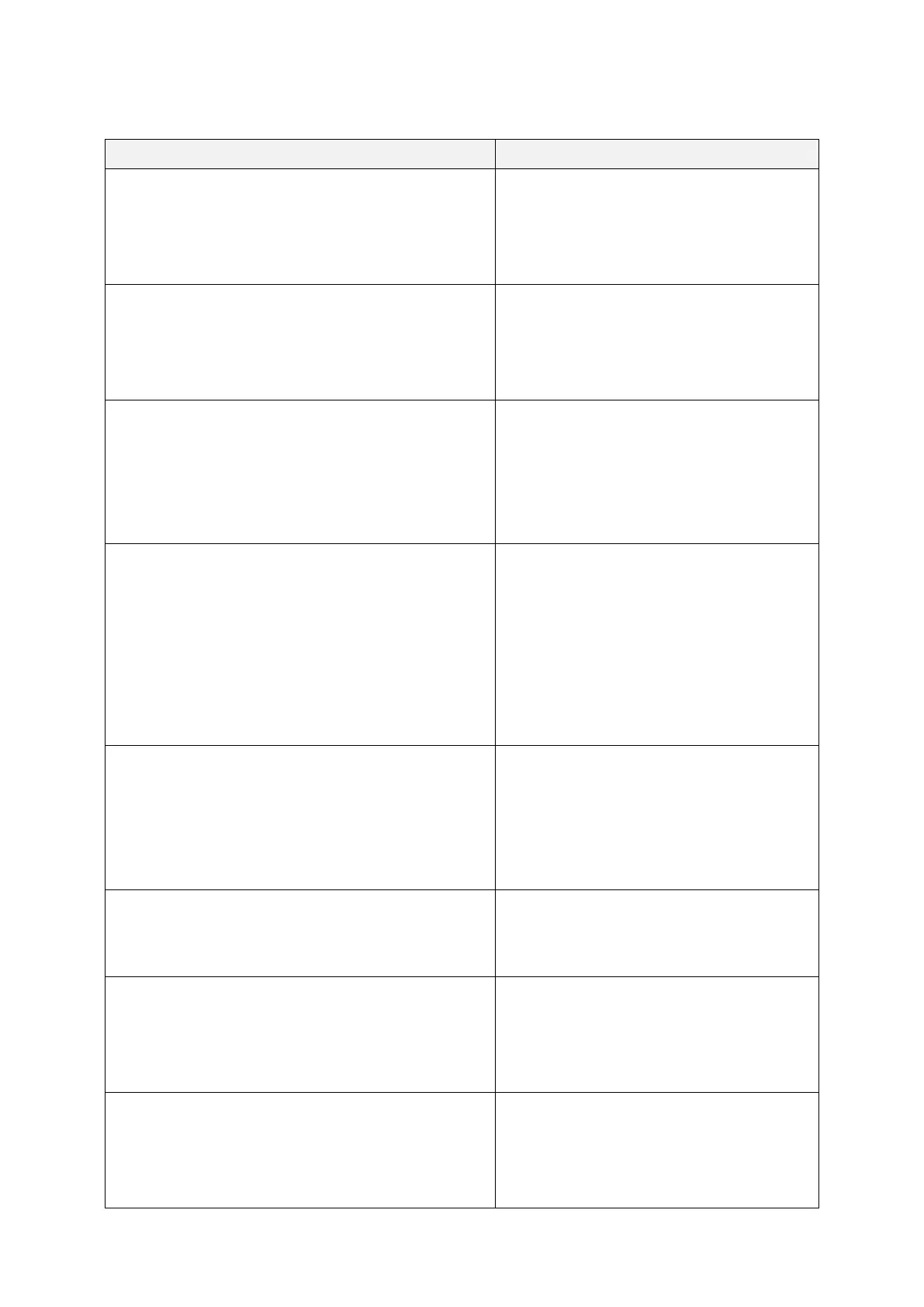

29

Electric circuit overheated.

Wait for cooling down to 70°C. Please contact

technical support if the problem persists after

Wait for the system to be cooled

down to 70 °C;

2) If the alarm is not removed, Please

contact our after-sales personnel

Stop using puller.

Wait for jaw to be cooled down to 90°C

Wait for the jaw to be cooled down to

90 °C;

2) If the alarm is not removed, please

contact our after-sales personnel

May be due to air leakage or other problems. Go to

[System Diagnosis] to explore.

Please contact technical support if problem

1) Enter [System Diagnosis] interface;

2) If the alarm is not removed, please

contact our after-sales personnel

Heating electric circuit abnormal. Please confirm

the heating filament has been installed and not

been burned out, and the temperature sensor

works properly, then restart. Or go to [System

Diagnosis] to determine heat value.

Please contact technical support if this problem

1) Restart or enter [System Diagnosis]

interface;

2) Replace a new filament;

3) If the alarm is not removed, please

contact our after-sales personnel

Failed to melt capillary glass. Heating filament may

be damaged or the Heat value may be too low

(please test Softening Point and turn on Safe Heat

mode)

Perform Softening Point test and turn

on Safe Heat mode;

2) Replace a new filament;

3) If the alarm is not removed, please

contact our after-sales personnel

Unable to check Heat. Please set softening point or

turn off safe heat mode (not recommended).

Set softening point or turn off safe heat

mode

Heat value should be in range of min-max, or turn

off safe heat mode (not recommended).

Reset softening point or turn off safe

heat mode;

2) If the alarm is not removed, please

contact our after-sales personnel

Jaw preheat time overlong. Softening point value

may be improper or heating assembly may have

been damaged. “Preheat jaws to 70°C” has been

Reset the softening point value;

2) Replace a new filament;

3) If the alarm is not removed, please

contact our after-sales personnel

Loading...

Loading...