Chapter 6: Programming Features

Firmware – S2011 and S3012

Revision: 1 (9/98) 60 © Saftronics, Inc.

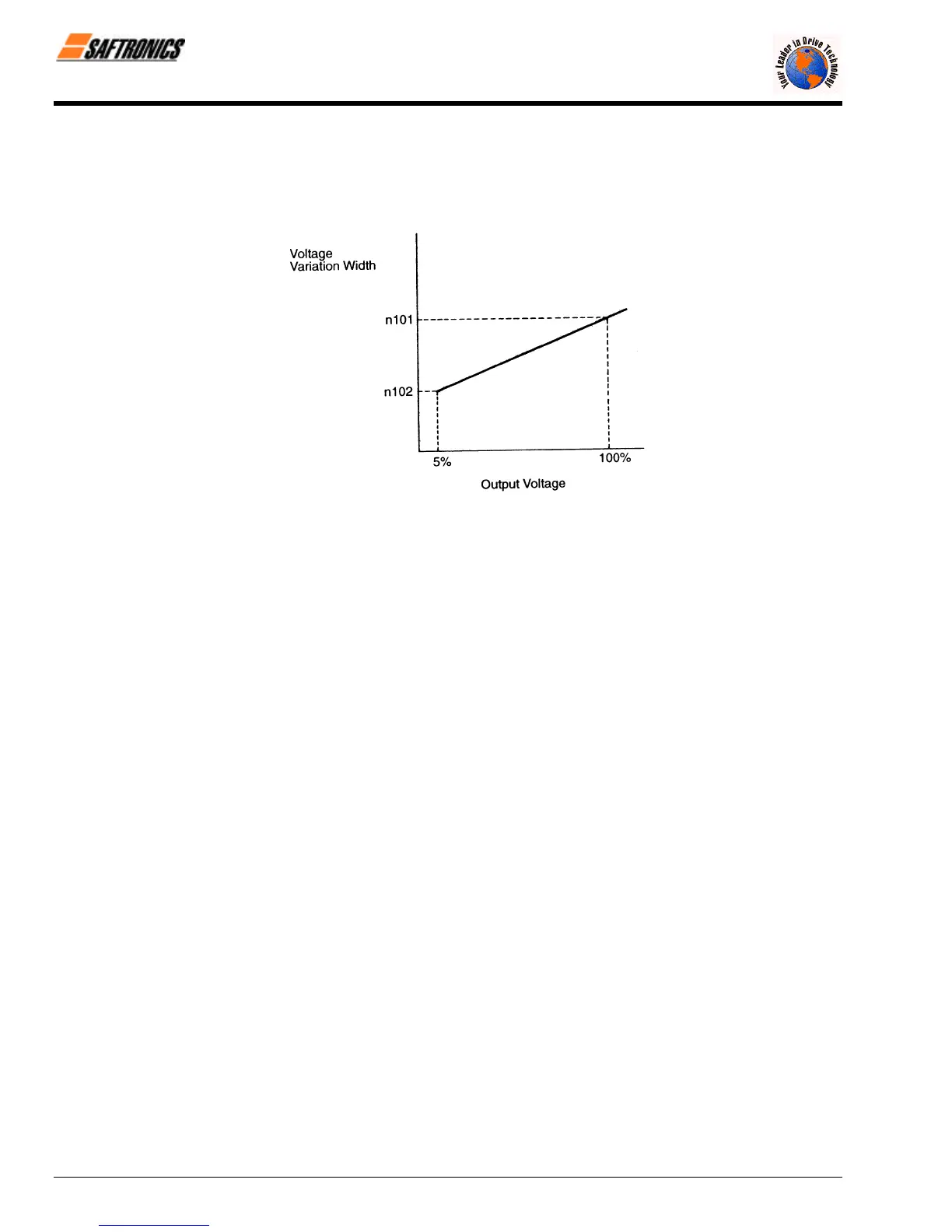

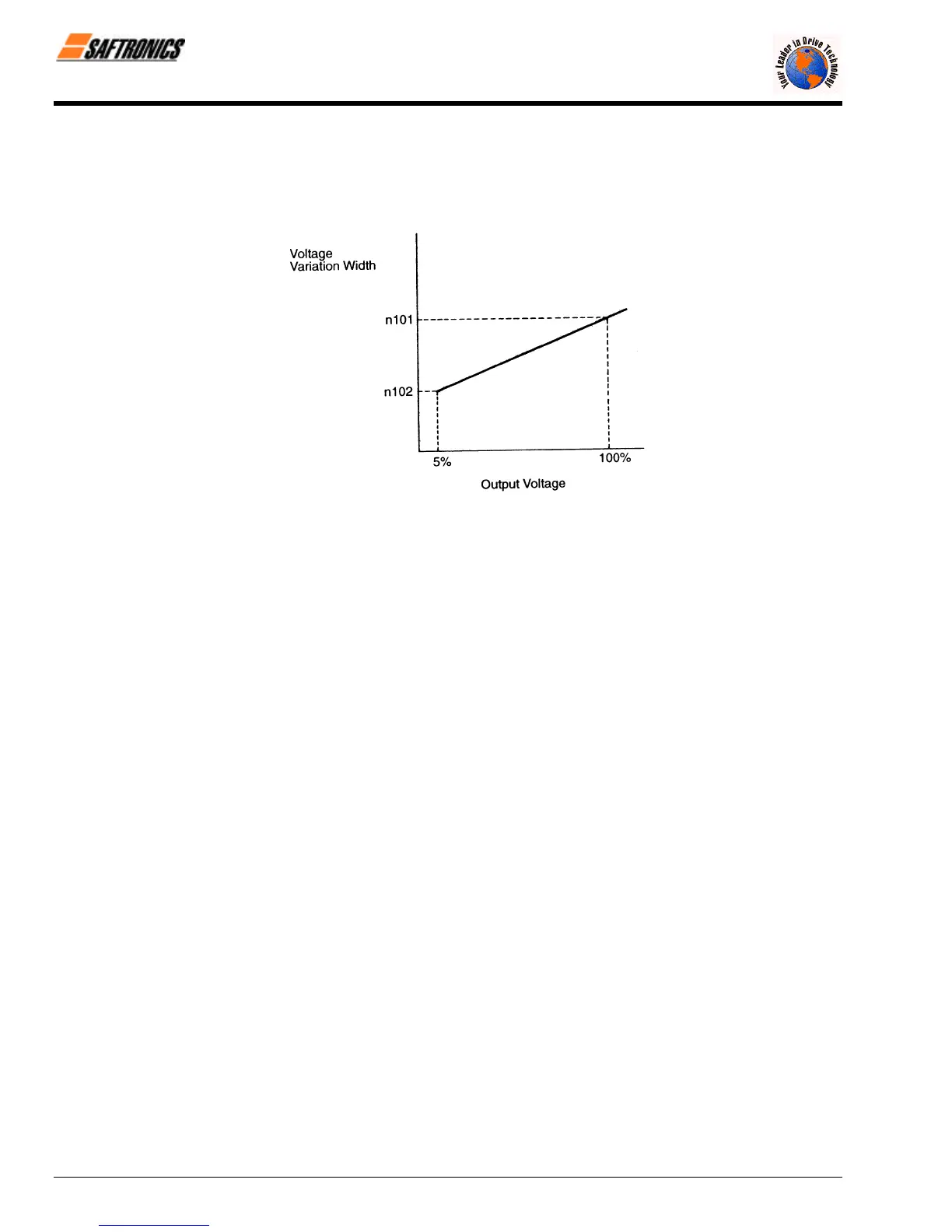

§ Step Voltage of Tuning (n100, n101)

Sets voltage variation width of one tuning cycle. Setting is made in a percentage of motor rated voltage. By

increasing this value, the rotating speed variation becomes larger. This voltage variation width is set when starting

tuning voltage is 100% and motor rated voltage is 5%. Values obtained by linear interpolation are set to any voltage

values other than these values.

Figure 51 Energy Saving Voltage Variation Width

6.10 MEMOBUS Control

FP5/GP5 can perform serial transmission by using a Programmable Controller (PLC) and MEMOBUS communication. MEMOBUS

is composed of one master PLC and 1 to 31 (maximum) slave units (FP5/GP5). In signal transmission (serial transmission)

between the master and slaves, the master always starts transmission and the slaves respond to it.

The master performs signal transmission with one slave at a time. Therefore, address numbers are assigned to each slave in

advance and the master specifies a number to perform signal transmission. The slave which receives the command from the

master executes the function and returns the response to the master.

6.10.1. Communication Specifications

• Interface

: RS-485 (Communication interface card SI-K2/P must be mounted.)

• Synchronization

: Asynchronous

• Transmission parameter

:

• Baud rate

: Selectable from 2400, 4800, 9600 BPS (Constant n107)

• Data length

: Fixed to 8 bits

• Parity

: Parity / no-parity, even / odd selectable (Constant n108)

• Stop bit

: Fixed to 1 bit

• Protocol

: In accordance with MEMOBUS

• Maximum number of units

to be connected

: 31 units (when RS-485 is used)

6.10.2. Data to be Sent/Received by Communication

Data to be sent/received by communication are RUN commands, frequency reference, fault contents, Inverter status and

constant setting/reading.

§ Operation Mode Selection (n002)

Select the RUN command and frequency reference input method in constant n002. To provide a RUN command

and frequency reference by communication, set this constant to settings 4 to 8. Also, without regard to this selection,

monitoring of running status, constant setting/reading, fault reset and multi-function input command from the PLC are

enabled. The multi-function input command becomes OR with the command input from control circuit Terminals S2

to S6.

efesotomasyon.com - Control Techniques,emerson,saftronics -ac drive-servo motor

Loading...

Loading...