31

Member of Exel group

DRT582221110

B - 2023/01

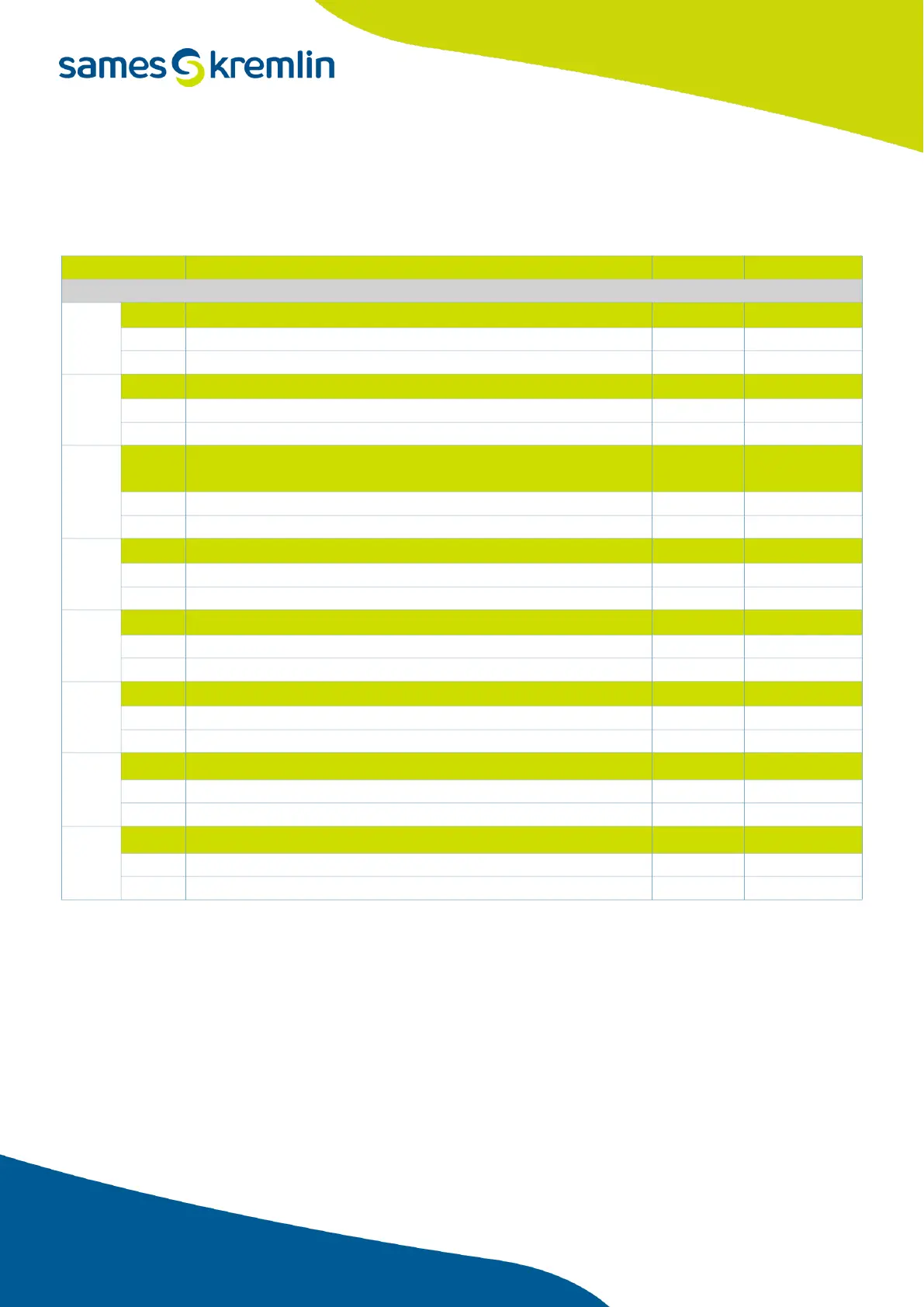

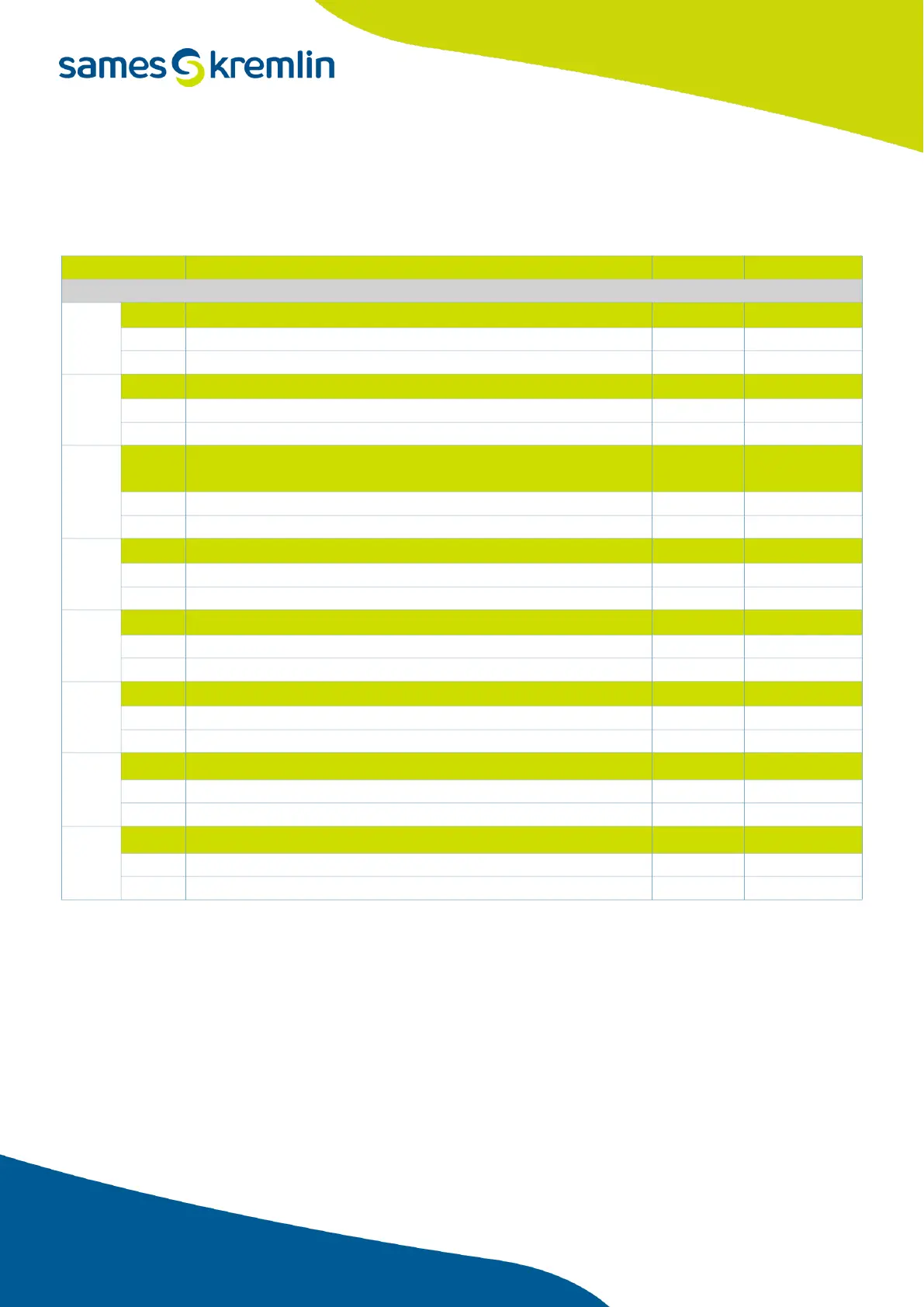

6.1. Maintenance summary table

The frequency of maintenance indicated in the procedures below is only indicative. The user will have to create his

own range of maintenance as he uses the Sames equipment.

(*)

Data for an average use of 8 hours per day.

ATTENTION: the values are given for use without leakage or poor condition of the parts.

Adapt the frequency of maintenance according to the use.

Procedure Detail Duration Frequency

Replacement

A

Maintenance of the aircap (2) and of the tip (3)

A1 Disassembly of the aircap (2) and of the tip (3) 15 s Daily

A2 Re-assembly of the aircap (2) and of the tip (3) 15 s Daily

B

Maintenance of the seat-holder assembly (4)

B1 Disassembly of the seat-holder assembly (4) 1 min 30 s Weekly

B2 Re-assembly of the seat-holder assembly (4) 1 min 15 s Weekly

C

Maintenance of the needle assembly (9) and of the air

valve (10)

C1 Disassembly of the needle assembly (9) and of the valve (10) 1 min 50 s Semestre

C2 Re-assembly of the needle assembly (9) and of the valve (10) 1 min 50 s Semestre

D

Maintenance of the fan adjustment valve (15)

D1 Disassembly of the fan adjustment valve (15) 15 s Semestre

D2 Re-assembly of the fan adjustment valve (15) 15 s Semestre

E

Maintenance of the trigger (5)

E1 Disassembly of the trigger (5) 30 s Annual

E2 Re-assembly of the trigger (5) 30 s Annual

F

Maintenance of the safety lever (5.5)

F1 Disassembly of the safety lever (5.5) 15 s Annual

F2 Re-assembly of the safety lever (5.5) 15 s Annual

G

Maintenance of the fluid tube assembly (21) (for Xcite

®

+)

G1 Disassembly of the fluid tube assembly (21) 1 min 50 s Semestre

G2 Re-assembly of the fluid tube assembly (21) 1 min 50 s Semestre

H

Maintenance of the fitting (16) (for Xcite

®

+ Light)

H1 Disassembly of the fitting (16) 20 s Semestre

H2 Re-assembly of the fitting (16) 20 s Semestre

Loading...

Loading...