122 EB 8389 EN

Appendix

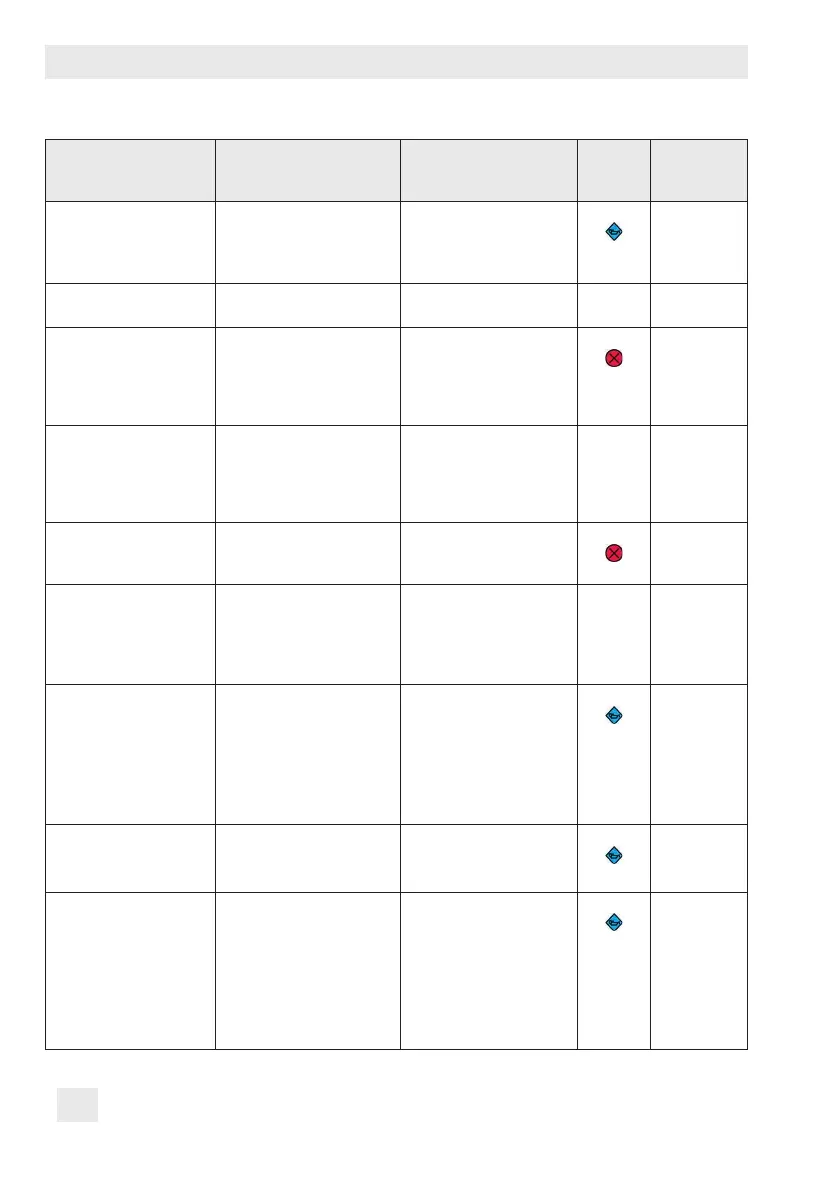

Message Possible reasons Recommended action

Status

classica-

tion Single reset

x signal (Code 62) − Actuator's measured value

recording failed.

− Conductive plastic element

defective.

Return positioner to

SAMSON for repair.

•

[

]

–

i/p converter (Code 64) Current circuit of i/p converter

interrupted.

Return positioner to

SAMSON for repair.

– –

Hardware (Code 65) − Hardware error

The valve is moved to fail-safe

position.

Conrm error and select

'Automatic' operating mode.

If not successful, reset

initialization and re-initialize

the positioner.

•

[

]

•

Data memory (Code 66) − No more data can be writ-

ten to the data memory.

The valve is moved to fail-safe

position.

Conrm error and select

'Automatic' operating mode.

If not successful, reset

initialization and re-initialize

the positioner.

– –

Control calculation

(Code67)

Hardware error has occurred. Conrm error. If this is not

possible, return positioner to

SAMSON for repair.

•

[

]

•

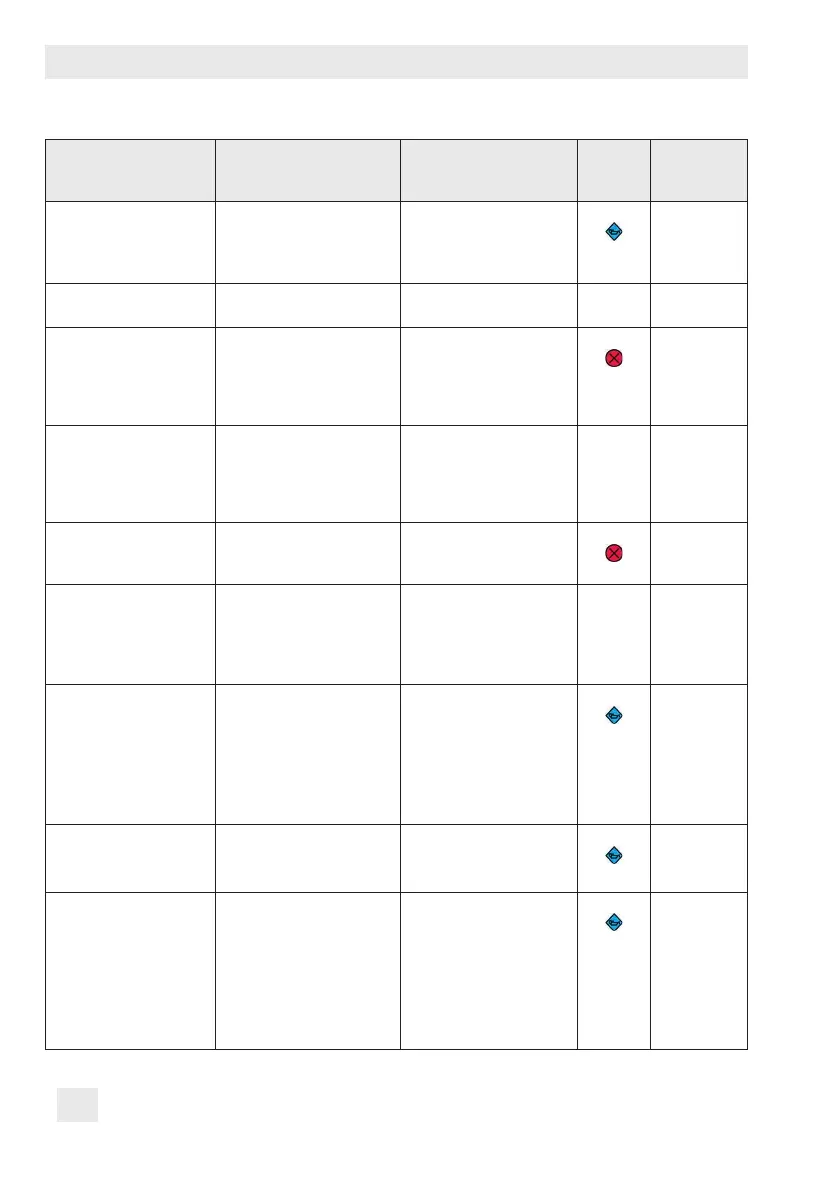

Program load error

(Code77)

− A program has been

loaded that does match the

positioner.

The valve is moved to fail-safe

position.

Interrupt current signal and

restart the positioner. If this is

not possible, return positioner

to SAMSON for repair.

– –

x > range (Code 50) − Pin not mounted properly.

− NAMUR attachment:

bracket slipped or follower

pin not properly seated on

the follower plate's slot.

− Follower plate not mounted

properly.

− Check attachment and

pin position.

− Re-initialize positioner.

•

[

]

•

Delta x < range (Code 51) − Pin not mounted properly.

− Wrong lever mounted.

− Pressure limit set too low.

− Check attachment and

pressure limit.

− Re-initialize positioner.

•

[

]

•

Attachment (Code 52) − Wrong lever mounted.

− Supply pressure too low;

valve cannot be moved to

desired position.

− Nominal range could not

be reached during nominal

range initialization

(NOM).

− Check attachment and

supply pressure.

− Re-initialize positioner.

•

[

]

•

Loading...

Loading...