EB 2512 EN 8-1

Malfunctions

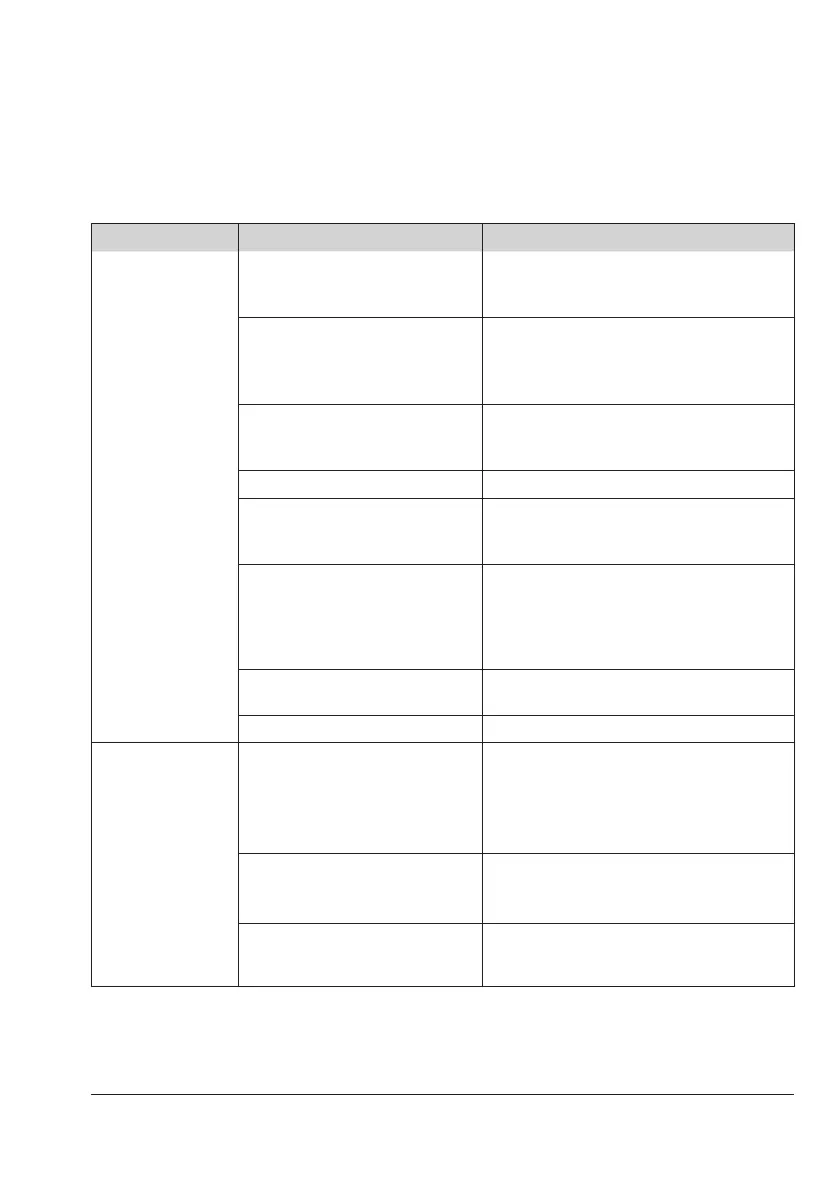

8 Malfunctions

8.1 Troubleshooting

Malfunction Possible reasons Recommended action

Downstream pressure

exceedstheadjusted

set point.

Insufcientpressurepulsesonthe

operating diaphragm

Î Connect the control line on site for regulators

withexternalcontrolline.

Î Cleanthecontrollineandscrewttings.

Foreign particles blocking the plug

Î Remove foreign particles.

Î When parts are damaged, contact SAMSON's

After-sales Service.

Seat and plug are worn or leak.

Î When parts are damaged, contact SAMSON’s

After-sales Service.

Control line blocked Î Cleanthecontrollineandscrewttings.

Pressure tapped at the wrong place

(regulatorwithexternalcontrolline)

Î Reconnect the control line at another point.

Î Do not connect the control line at pipe bends or

necks.

Regulator or K

VS

/C

V

coefcienttoo

large

Î Checkthesizing.

Î Change K

VS

/C

V

coefcient,ifnecessaryor

installadifferentsizedregulator.

Î Contact SAMSON's After-sales Service.

Compensation chamber in the wrong

position or too small (with steam)

Î Reconnect compensation chamber at a different

placeorreplaceit(seeAnnex).

Defective operating diaphragm Î Replace damaged diaphragm.

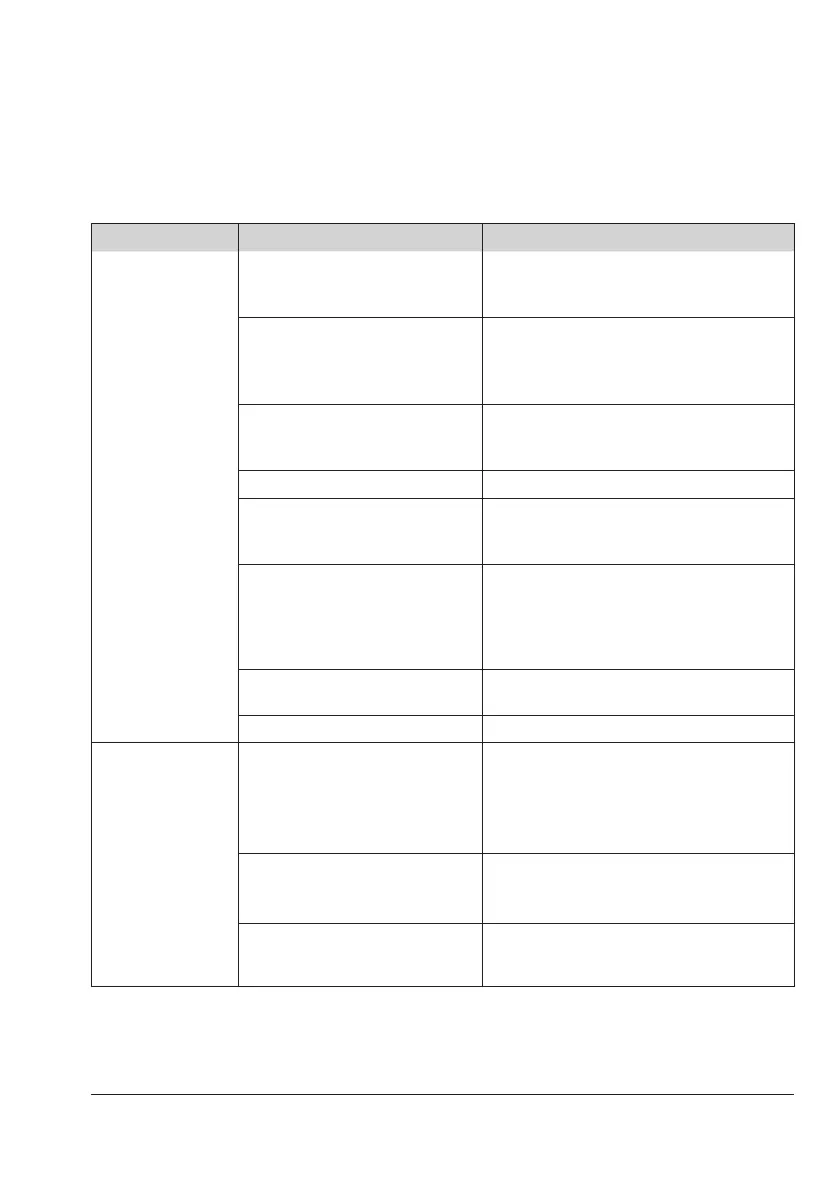

Downstream pressure

hunts

Regulator or K

VS

/C

V

coefcienttoo

large

Î Checkthesizing.

Î Change K

VS

/C

V

coefcient,ifnecessaryor

installadifferentsizedregulator.

Î Contact SAMSON's After-sales Service.

Pressure tapped at the wrong place

(regulatorwithexternalcontrolline)

Î Reconnect the control line at another point.

Î Do not connect the control line at pipe bends or

necks.

The restriction in the control line for

pressure tapping is too large or

missing.

Î Install a restriction.

Î Install a smaller restriction.

Loading...

Loading...