SINUS MINI High performance Vector Control Inverter User Manual

46

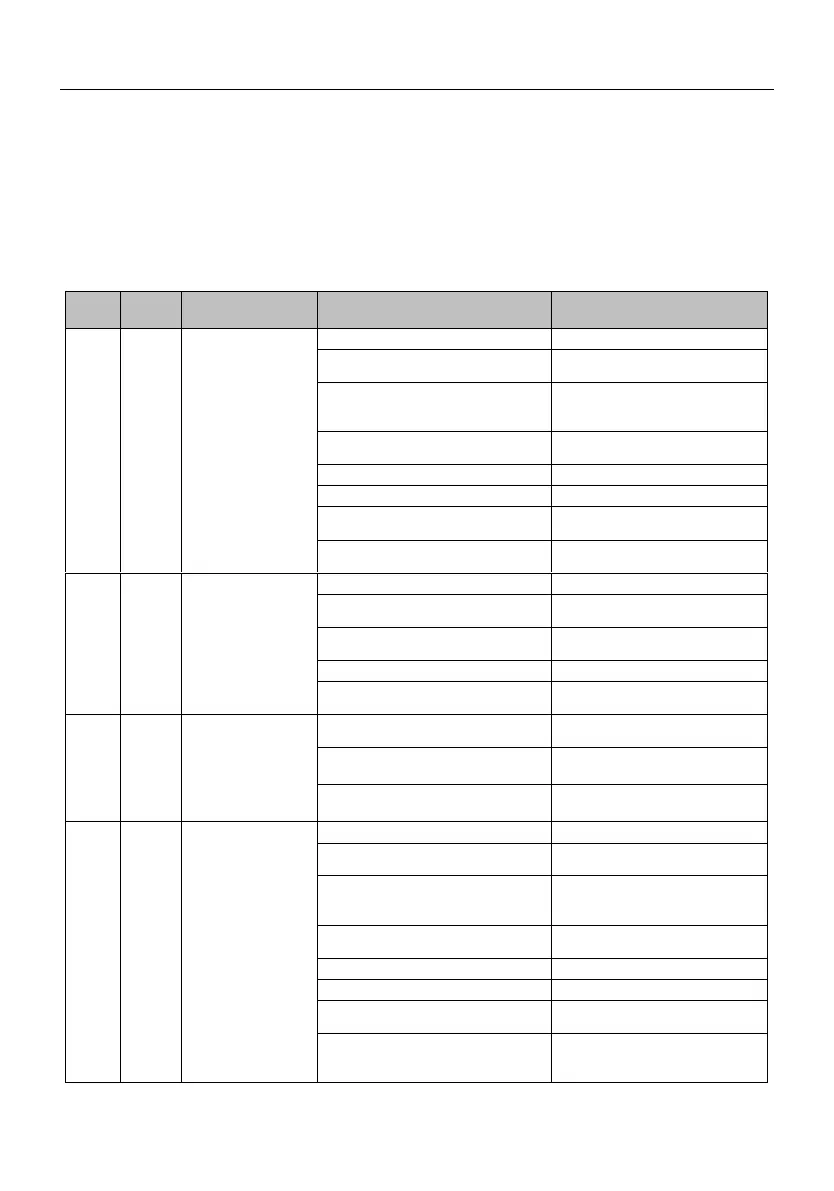

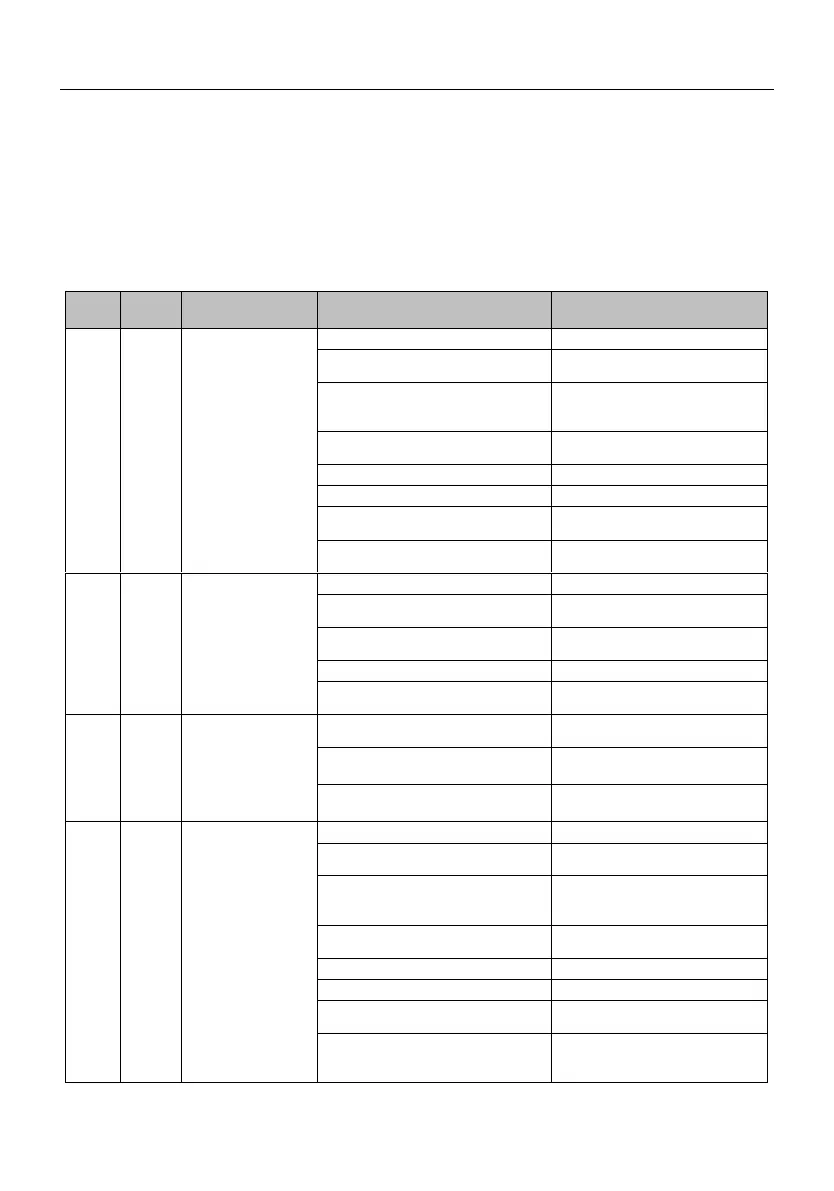

5.2 List of Fault and Alarm Information

SINUS MINI serial inverter is equipped with complete protection functions to provide efficient protection

while utilizing its performance sufficiently. Some failure instructions may be displayed during operation.

compare the instructions with the following table and analyze, decide the causes and solve failures.

For damages on units or questions that can’t be resolved, please contact with local distributors/agents,

service centers or manufacturer for solutions.

Over current

protection when

acceleration

operation

Start-up too fast during motor

operation

Restart after the motor stops

rotating

Rotating inertial of load is very large

and shock load is very heavy

Increase the acceleration time

and reduce the occurrences of

sudden change of load

Improper setting of motor

parameters

Set motor parameters properly

Set start-up frequency too high

Decrease start-up frequency

Acceleration time is too short

Lengthen acceleration time

Set V/F curve ratio too large

Adjust V/F curve setting and

torque boost

Power level of inverter is small

Replace with inverter with proper

model

Over current

protection when

deceleration

operation

Rotating inertial of load is too large

Choose appropriate energy

braking components

Improper setting of motor

parameters

Set motor parameters properly

Deceleration time is too short

Lengthen deceleration time

Power level of inverter is small

Replace to inverter with proper

model

Over current

protection when

operation with

constant speed

Sudden change of load during

operation

Decrease load’s abrupt frequency

change and amplitude

Improper setting of motor

parameters

Set motor parameters properly

Power level of inverter is small

Replace to inverter with proper

model

IGBT module

protection in Acc

process

Start-up too fast during motor

operation

Restart after the motor stops

rotating

Rotating inertial of load is very large

and shock load is very heavy

Increase the acceleration time

and reduce the occurrences of

sudden change of load

Improper setting of motor

parameters

Set motor parameters properly

Set start-up frequency too high

Decrease start-up frequency

Acceleration time is too short

Lengthen acceleration time

Set V/F curve ratio too large

Adjust V/F curve setting and

torque boost

Power level of inverter is small

Replace with inverter with proper

model

Loading...

Loading...