6

10/01

Foreword _______________________________________________________________________________________________________________________________

1. FFOREWORD

11..11.. PPrreeccaauuttiioonnss

The control unit is connected to various AC voltage sources (alternator, mains, ...).

If work inside the control panel is required, it must be performed by staff authorised to work live.

These fuses must be replaced when the generating set is in complete shutdown. For any voltage measurement on these four fuses, please

use suitable equipment.

The generating set can be equipped with a remote start-up (simple contact) or with an automatic starting system [mains failure + ATS

(Mains/Stand-by changeover switch)] .

11..22.. PPoowweerr ccoonnnneeccttiioonn

For power connection, make sure that flexible cables of suitable cross section are used to avoid overheating and a major in-line voltage drop.

Depending on laying method, ambient temperature and proximity of other cables, the conductor's cross section may vary.

11..33.. EElleeccttrriicc ccoonnnneeccttiioonnss ((ccoonnttrrooll))

Generating sset wwith mmanual sstart oonly

(from the control unit keyboard)

No external connection to make.

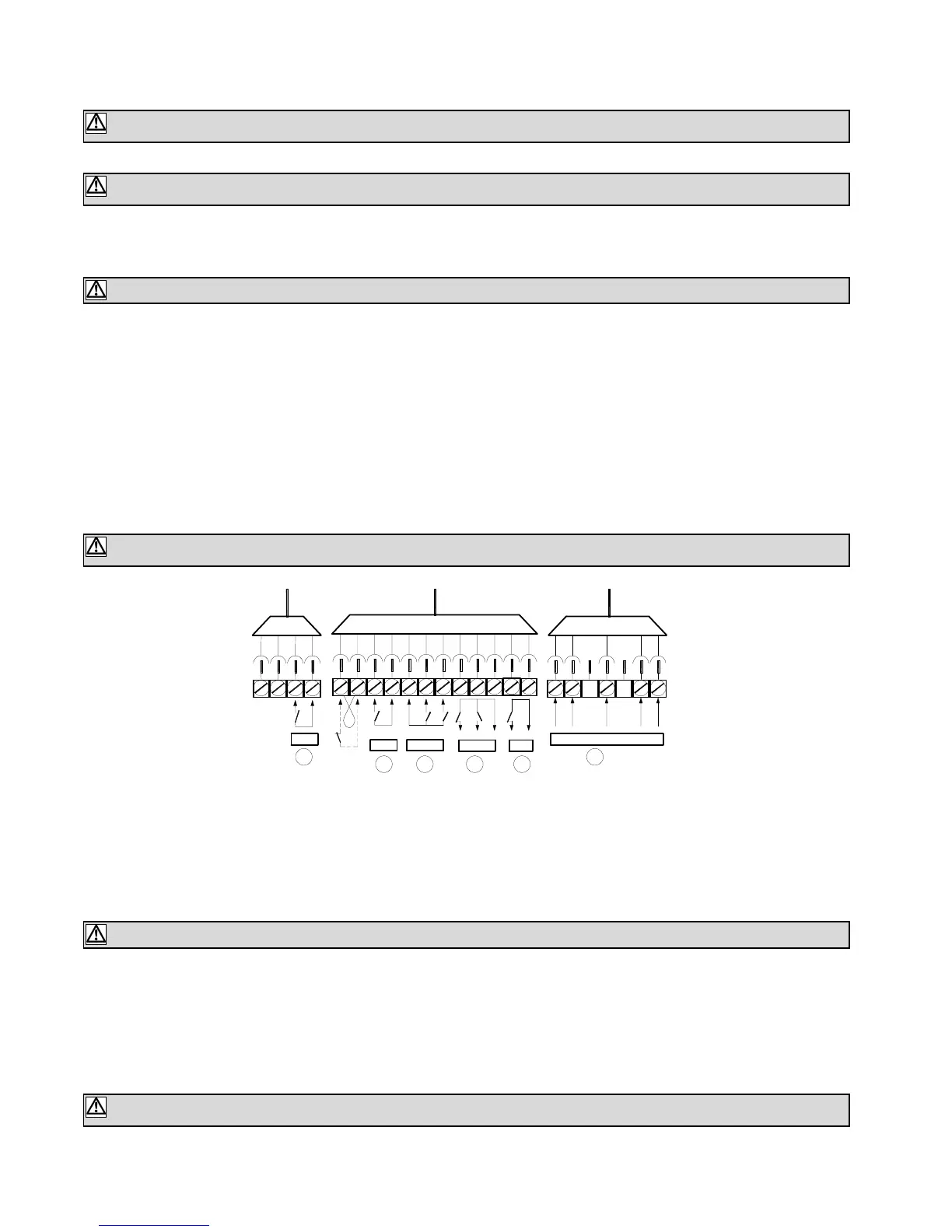

Generating sset wwith rremote ((without mmains) oor aautomatic ((with mmains) sstart-uup

For proper operation, make the connections on the user terminal block as per the diagram below.

For DC signals, we recommend the use of a 5-core (5x1.5mm²) flexible cable between the ATS and the user terminal block.

For AC signals, we recommend the use of a 12-core (12G1.5mm²) flexible cable between the ATS and the user terminal block.

(G means cable with a Green/Yellow conductor)

Note: for a remote start only, a 2x1.5mm² flexible cable is sufficient (see overleaf)

External command (mains sensing or client contact) Output C/B fault auxiliary signal contact

Mains and Stand-by contactors home position Stand-by contactor control

Mains contactor control 1 or 3 phase water heater

If the user does not connect an ATS from our range, it is imperative to observe the board relay characteristics given below and to check

that the coils power requirements are within these parameters.

Rated ccurrent=5A Rated vvoltage=250Vac

Maximum bbreaking ccapacity uunder aa 00.7 ccos ϕϕ: 11500VA

11..44.. BBaatttteerryy pprreelliimmiinnaarryy iinnssppeeccttiioonn aanndd ccoommmmiissssiioonniinngg

The battery must be connected for the control unit to operate and the generating set to start, hence the need to check its connection:

Red wire, positive polarity (

+

),

Black wire, negative polarity (

-

).

Some generating sets are equipped with a battery isolator enabling the electric circuit to be isolated. Check that it is in the position enabling

the operation.

Beware of possible electric shock by contact with any live part, during the generating set start up.

While the generating set is idle, any work inside the control equipment is strictly forbidden as some parts of the electric and elec-

tronic equipment stay live (mains voltage available).

When the generating set is running, the fuses marked

Fn

,

F1

,

F2

,

F3

are at a dangerous potential which can lead to electric shock

when touched.

The cross sections above are given as a guide as they can vary depending on the current to be drawn, length, temperature and

control cable laying method.

Not observing the above characteristics will damage or even destroy the board control relays.

The battery is supplied without electrolyte. Fill the battery with electrolyte at least 20 minutes before any start-up attempt (see main-

tenance manual).

Loading...

Loading...