6-4

Chapter 6 COOLANT

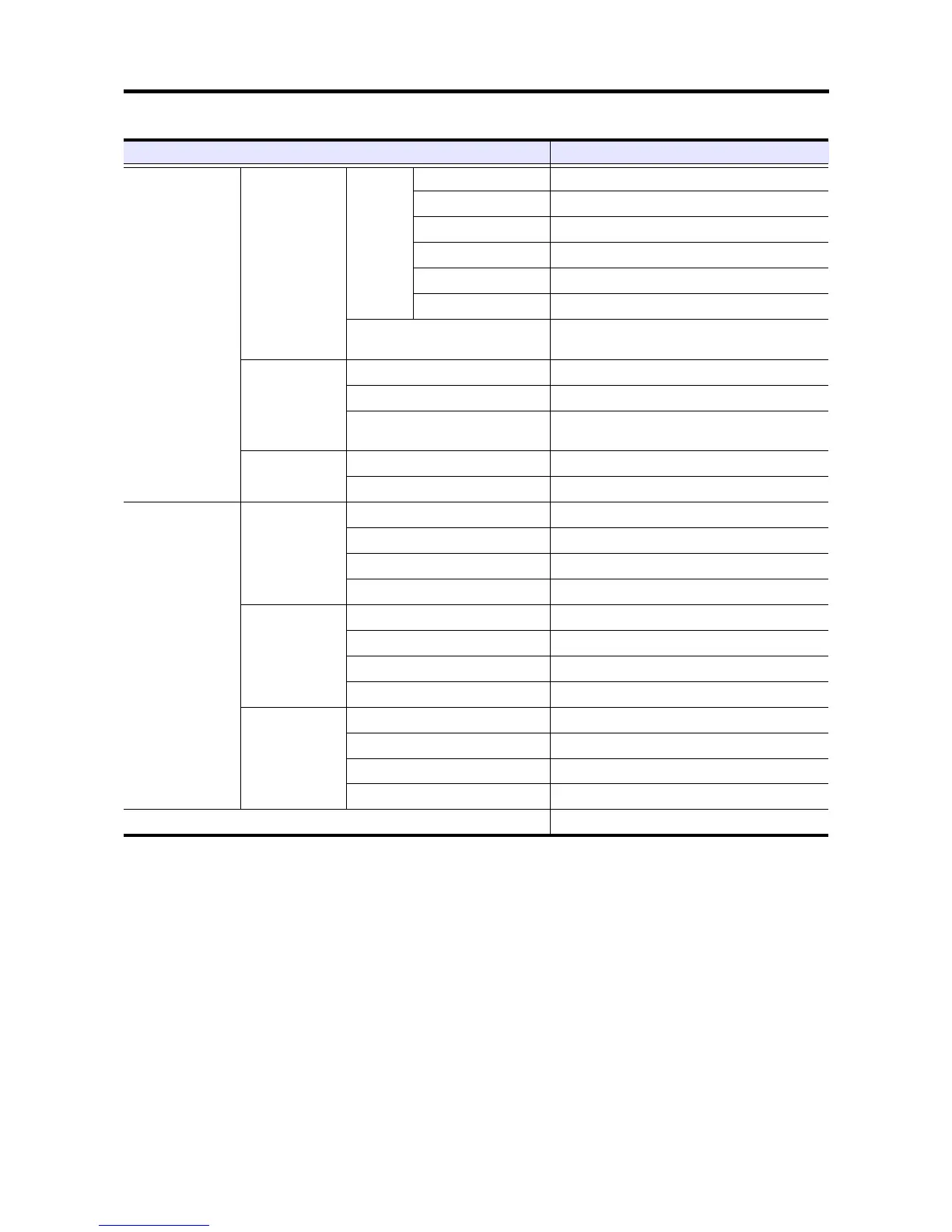

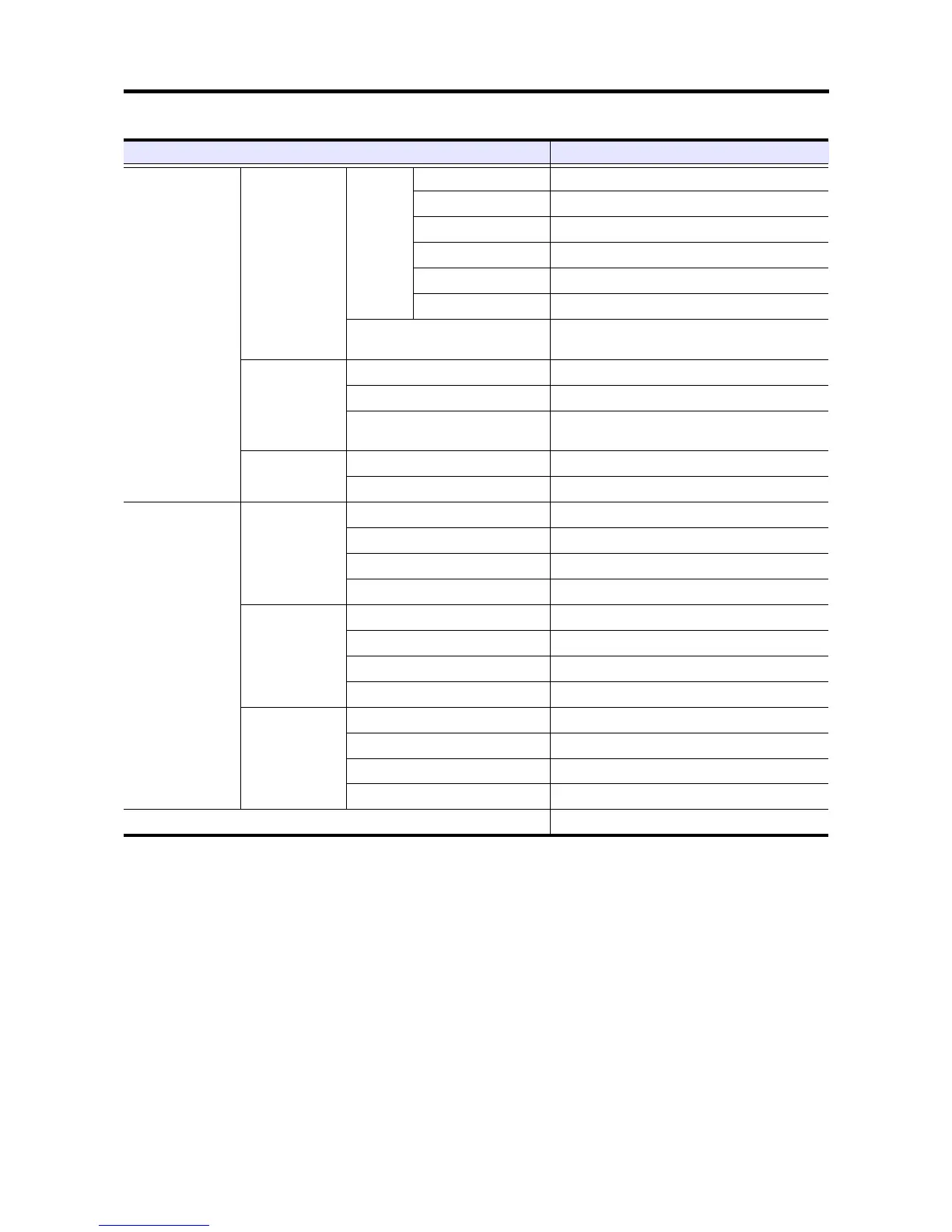

Circulation

metallic causticity

(88±3°C

[190±37°F],

1000±2 Hr,

30 vol % (E.G))

Test piece

Mass

change

Aluminum ±0.60 mg/cm

2

Cast iron ±0.30 mg/cm

2

Steel ±0.30 mg/cm

2

Brass ±0.30 mg/cm

2

Solder ±0.60 mg/cm

2

Copper ±0.30 mg/cm

2

External of test piece after the

examination

Not corrosion on surface excluding between

test piece and spacer. Discoloration is OK.

Properties of

liquid after the

examination

pH 6.5 to 11.0

pH change Maximum ±1.0

External of liquid

Not remarkable discoloration, separation

and gel.

Condition of

parts

Pump seal Not trouble while the examination

Inside of pump case and blade Not remarkable corrosion

Rubber

adaptability

(30 vol %,

115°C [239°F],

360 Hr)

Silicon

Tensile strength change -60 to 0 %

Elongation change -40 to +20 %

Volume change 0 to +40 %

Hardness change -20 to +10 %

Acrylonitrile

butadiene

rubber

Tensile strength change 0 to +10 %

Elongation change -15 to +15 %

Volume change 0 to +40 %

Hardness change -10 to 0 %

Ethylene

propylene

diene monomer

Tensile strength change 0 to +10 %

Elongation change -30 to 0 %

Volume change 0 to +10 %

Hardness change -10 to 0 %

Storage stability vol % (30 vol %, room temperature, 6 Hr) Maximum 0.3

Table 6-2 LLC specification

Property Standard

Loading...

Loading...