8-14

Chapter 8 PERIODIC INSPECTION AND MAINTENANCE PROCEDURES

Inlet and exhaust systems

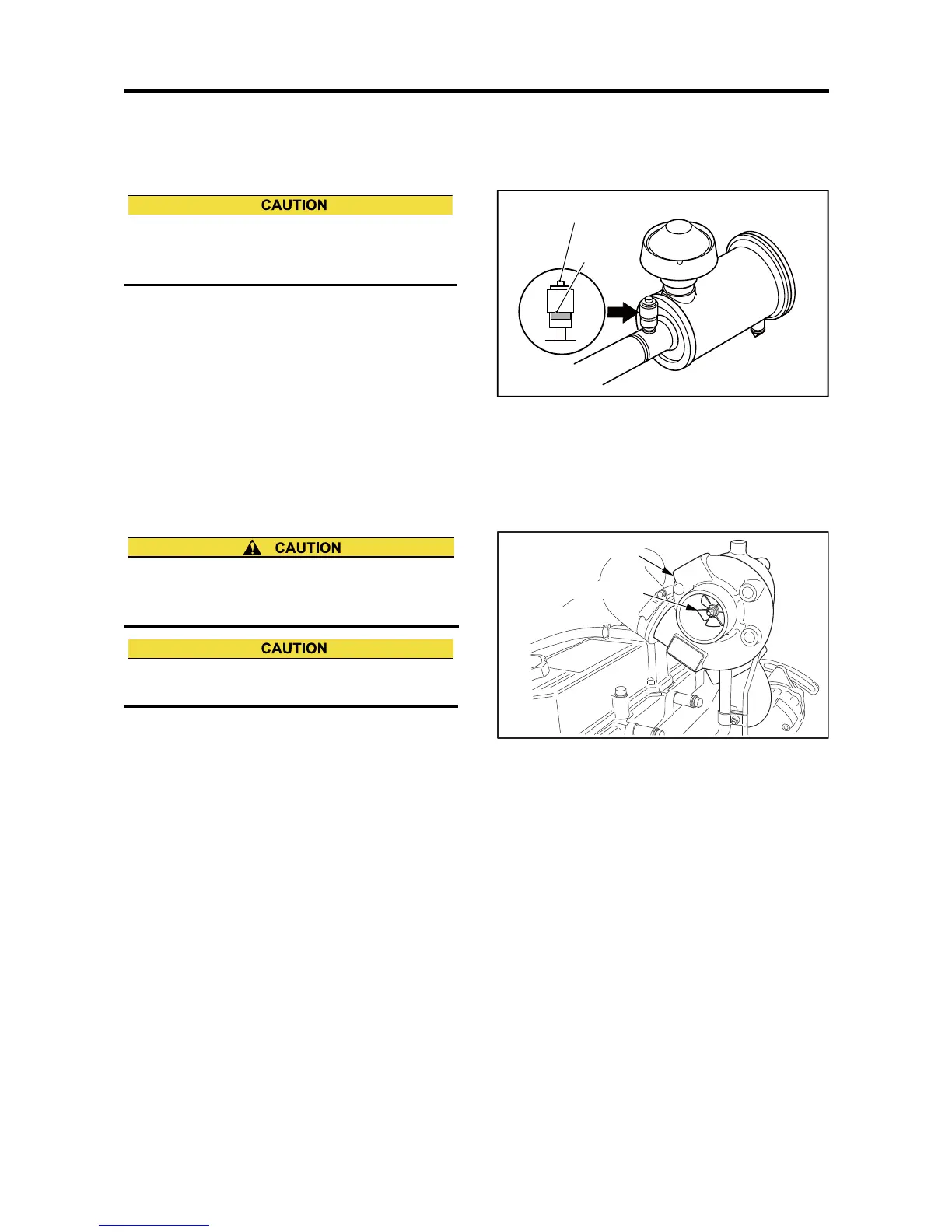

Air cleaner - Check

1. Check the air cleaner indicator for the element

clog.

2. If the element is clogged, the red signal mark is vis-

ible.

3. Immediately clean or replace the air cleaner ele-

ment when the signal turns red.

Note: For cleaning of the air cleaner element, refer to

"Air cleaner element - Clean, Check and Re-

place" (8-16).

Fig. 8-23 Air cleaner - Check

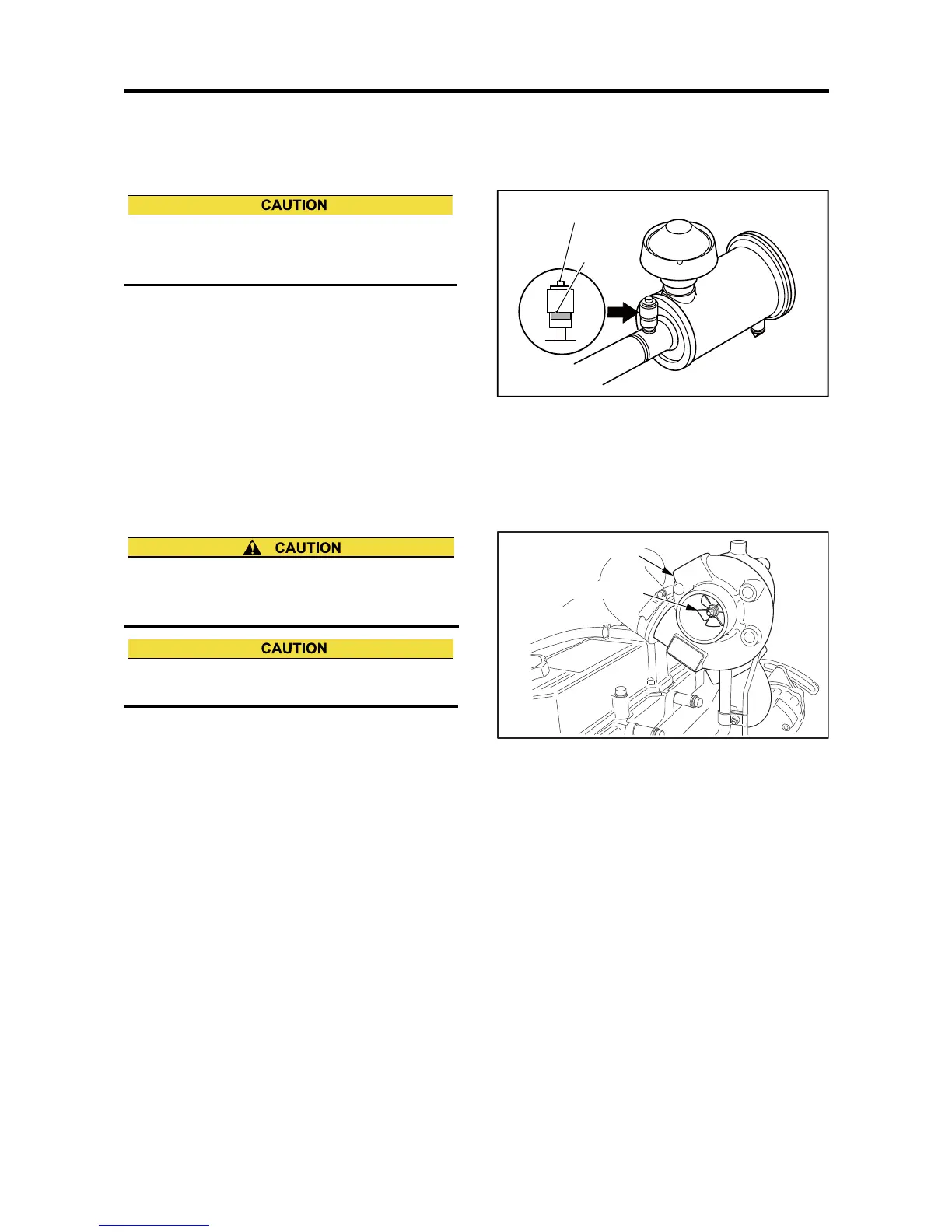

Turbocharger - Inspect

Disconnect the pipe from the air inlet side. Hold the

compressor wheel nut by hand and turn the wheel to

check for looseness or abnormal noise. Replace the

turbocharger if looseness or abnormal noise is found.

Note: When removing an

d inspecting turbocharger,

contact a dealer of Mitsubishi Heavy Industries,

Ltd.

Fig. 8-24 Turbocharger - Inspect

Checking procedure described below is a commonly

used procedure. Some application may be equipped

with different air cleaner.

Reset

button

Signal

(red)

Check the turbocharger when the engine is cold.

Also, make sure that the compressor wheel is not

rotating before inspecting the turbocharger.

If the color of the exhaust gas is abnormal, also

inspect the turbocharger.

Turbocharger

Compressor wheel

Loading...

Loading...