3.2.2 - Mechanical checks

Before starting the machine for the rst time, check that:

- the xing bolts on the feet are tight,

- the cooling air is drawn in freely,

- the protective grilles and housing are correctly in place,

- the standard direction of rotation is clockwise as seen from

the shaft end (phase rotation in order 1-2-3). For anti-clockwise

rotation, swap 2 and 3.

- the winding connection corresponds to the site operating

voltage (see section 3.3).

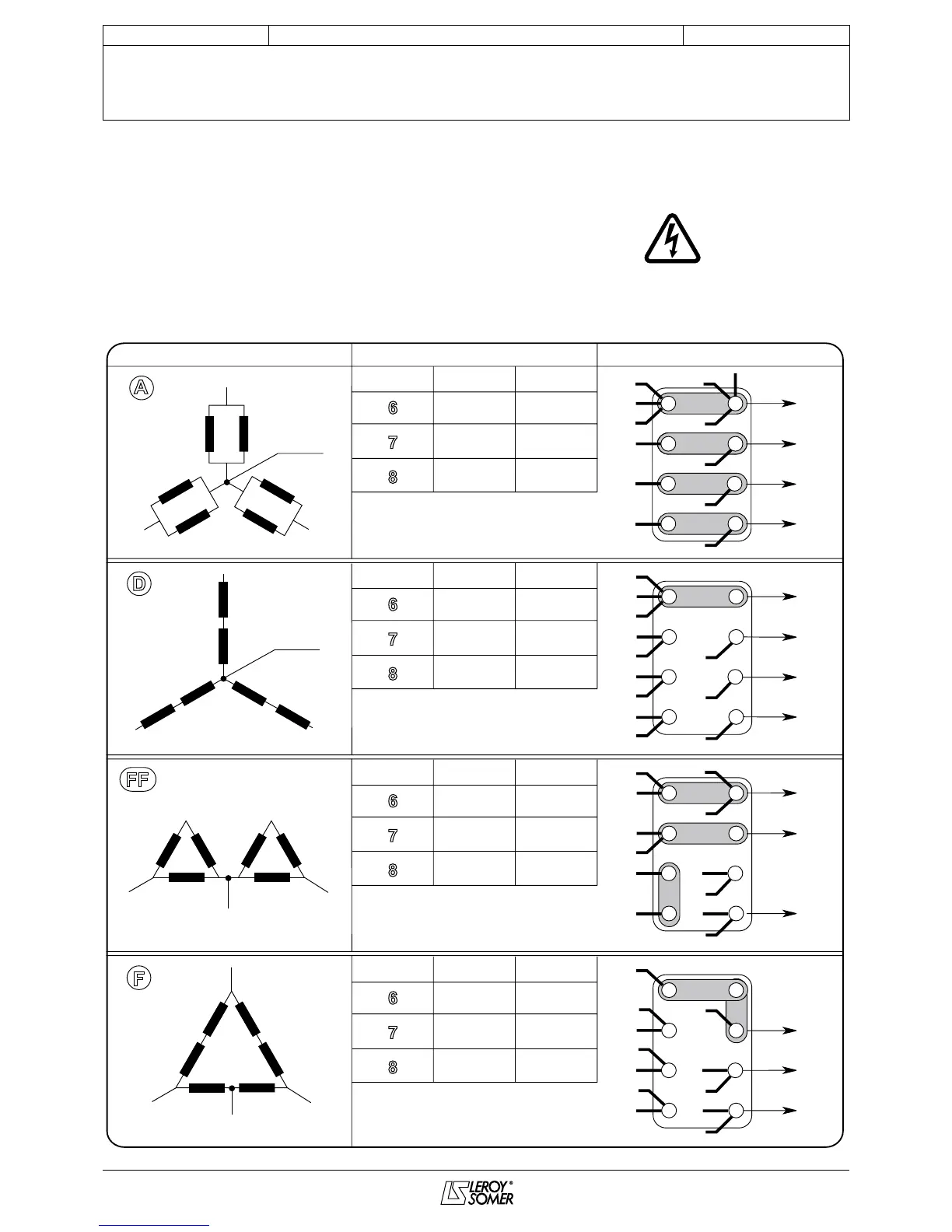

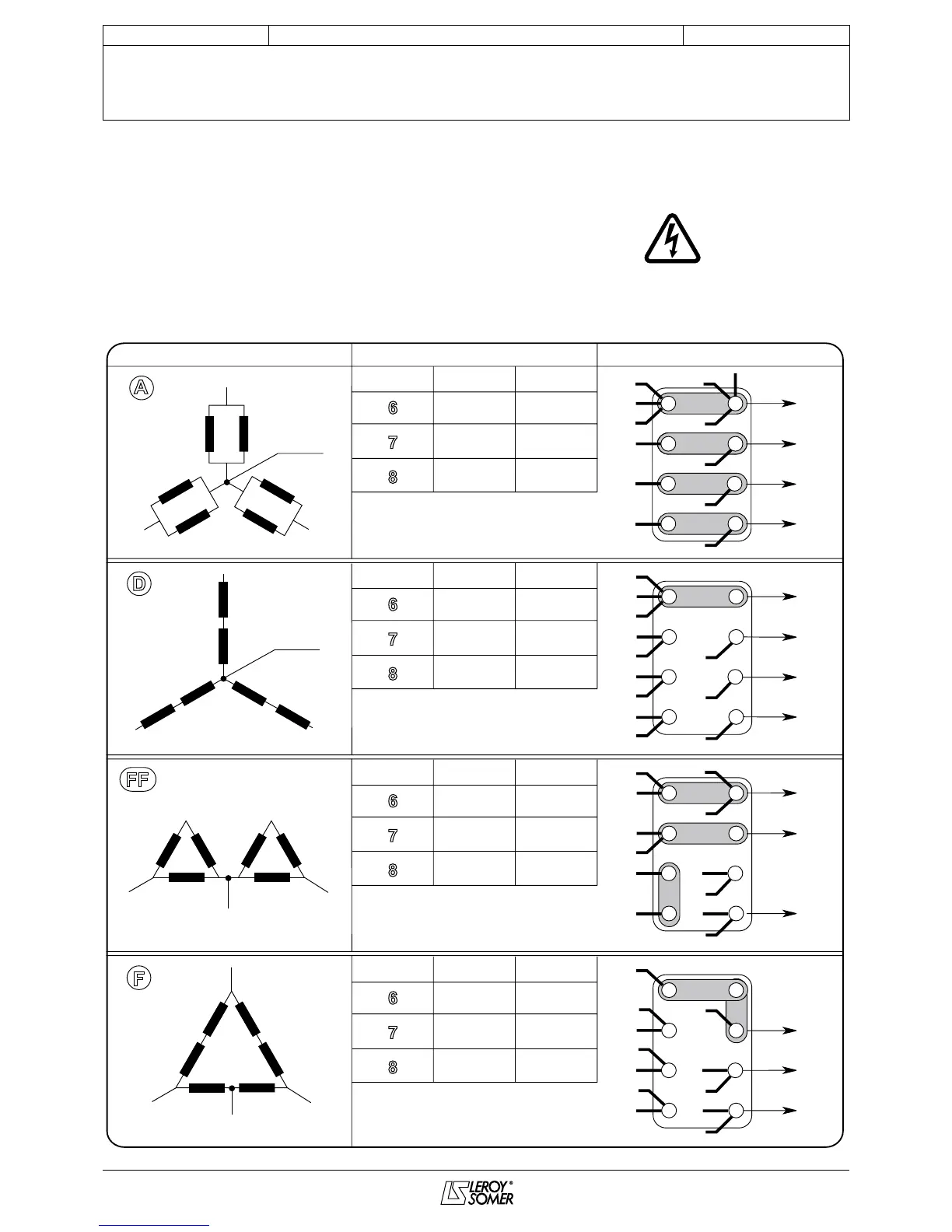

3.3 - Terminal connection diagrams

To modify the connection, change the position of the terminal

cables. The winding code is specied on the nameplate.

Any intervention on the alternator terminals during

reconnection or checks should be performed with the

machine stopped.

R 250 voltage sensing:

0 => (T8) / 110 V => (T11)

R 438 voltage sensing:

0 => (T3) / 220 V => (T2)

Connections codes

L.L voltage

Winding

Winding

Winding

Winding

3 phases

3 phases

1 phase

1 phase

or

3 phases

Factory connection

R 250 voltage sensing:

0 => (T8) / 110 V => (T11)

R 438 voltage sensing:

0 => (T3) / 380 V => (T2)

R 250 voltage sensing:

0 => (T1) / 110 V => (T4)

R 438 voltage sensing:

0 => (T10) / 220 V => (T1)

LM voltage = 1/2 LL voltage

LM voltage = 1/2 LL voltage

R 250 voltage sensing:

0 => (T8) / 110 V => (T11)

R 438 voltage sensing:

0 => (T3) / 220 V => (T2)

AR

AR

AR

AR

INSTALLATION AND MAINTENANCE

LSA 43.2 / 44.2 - 4-poLe

ALTeRNAToRS

3434 en -

Loading...

Loading...