63

English

loadmanagementsystemtothenextWallbox.

Pleasenote:

• Two conductors per bus line are used.

• Connectthebususingtwoseparatebuslines

eachbetweentheWallboxes(Lineinand

Lineout).

• Connectonlyonebuslineeachtotherst

(Lineout)andlast(Linein)devices.

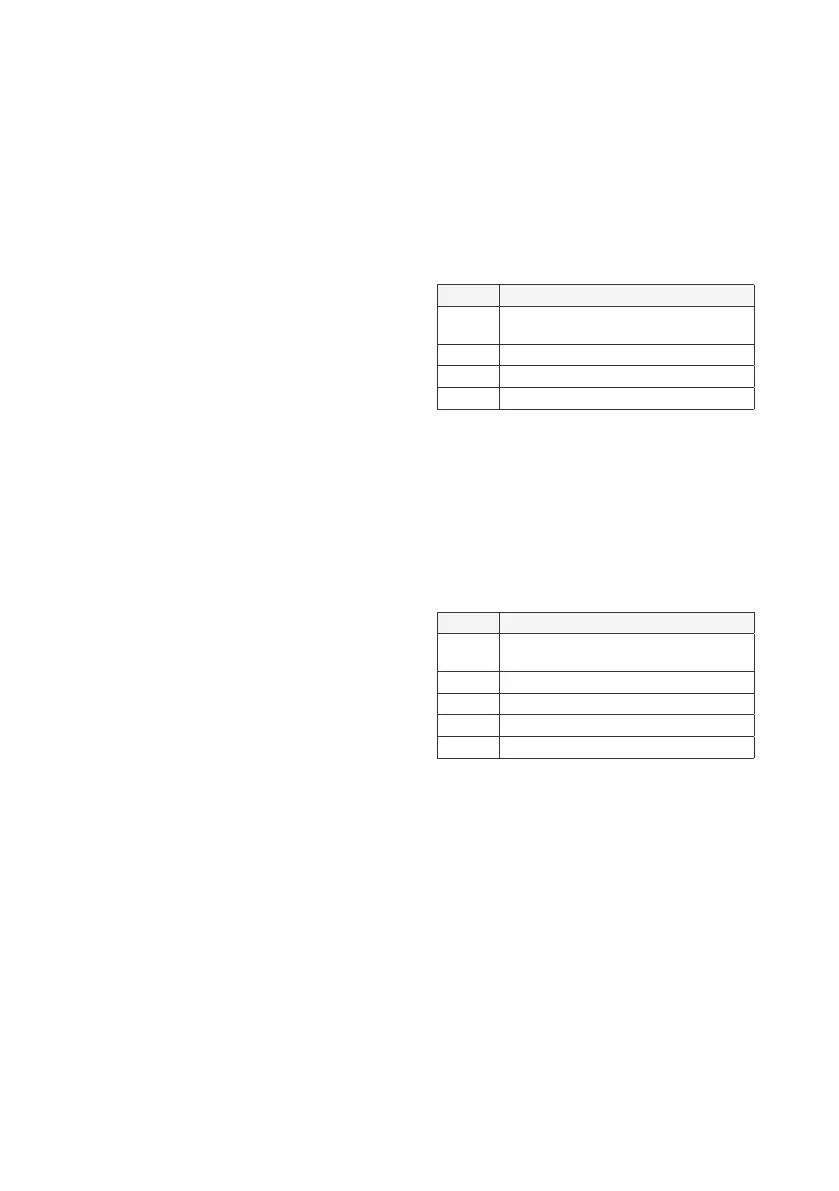

Figs. IX and Xareexplainedbelow

Item Designation

1

FirstWallboxorexternalload

management on the bus

2 SecondWallboxonthebus

3 WallboxXonthebus

4 LastWallboxonthebus

2.3 Bus system with central wiring

indistributor

Centralwiring(Figs. XI, XII and XIII)differsasfollows:

• Four conductors per bus line are used.

• Onlytwoconductorseachareneededontherst

and last devices.

• Connectthescreensoftheindividualbuslinesin

the central distributor.

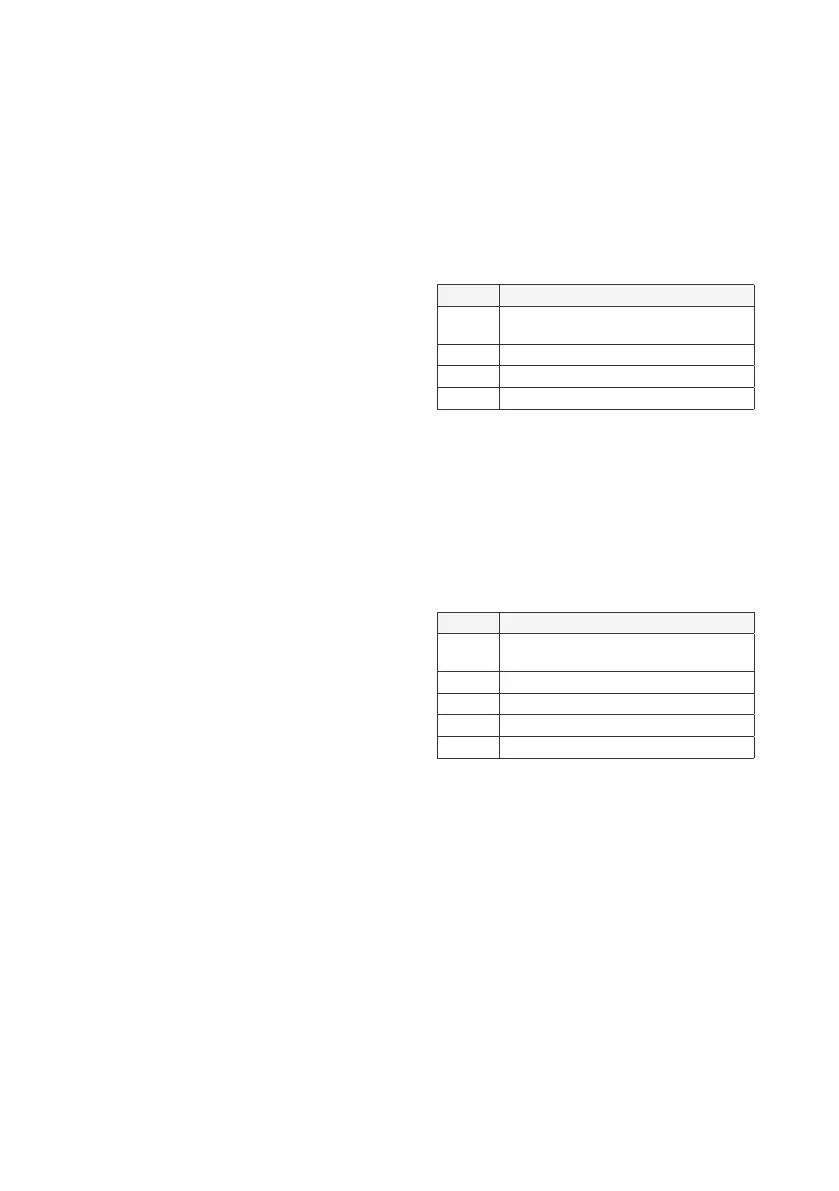

Figs. XII and XIIIareexplainedbelow

Item Designation

1

FirstWallboxorexternalload

management on the bus

2 SecondWallboxonthebus

3 WallboxXonthebus

4 LastWallboxonthebus

5 Centraldistributor

3. Local and external load management

Inlocalloadmanagementmode,severalWallboxes

arenetworkedviaanRS485bus.TheseWall-

boxessharetheavailabletotalcurrentequally.An

externalcontrolsystemisnotnecessaryinthiscase.

Activatingthismodedoesnotrequiremakingany

communicationsettings.Pleaseobservetheinfor-

mationonconguringandinstallingtheWallboxes.

Inexternalload/energymanagementmode,the

Wallboxesarenetworkedwithanexternalcontrol

system(e.g.HEMS–HomeEnergyManagement

System)viaanRS485bus.

Theexternalcontrolsystem(leader)managesthe

system and communicates with all connected

Wallboxes(followers).Theexternalcontrolsystem

controls the energy distribution. This approach

enables solar energy or an energy storage system

1. Introduction

TheSENEC.Wallboxprosisusedtocharge

plug-inhybridorelectricvehicles.SeveralSENEC.

Wallboxprosunitscanbeoperatedinanintegrated

network.Thisenablesthepowerdistributiontobe

monitoredforupto16Wallboxes.Intheinterestof

simplicity,the‘SENEC.Wallboxpros’willbeshort-

enedto‘Wallbox’below.Theintegratednetworkcan

beimplementedintheformoflocalorexternalload

management.

Fig. V showsanintegratednetworkcomprisingve

Wallboxesasanexample.Inanintegratednetwork

ofveWallboxes,theenergysupplyprovidesup

to32Aofcurrent.TheWallboxesarepre-setwith

I

max

16AandI

min

6A.Thetotalchargingcurrent

(32A)isdistributedequally.Ifavehiclehasended

its charging process but remains connected to the

Wallbox,thisvehiclewillcontinuetobeprovided

with6Aofcontinuouscurrent(fortheauxiliary

heater,forexample),insomecasesalternatelywith

other vehicles which have already been charged.

2. Installation of the bus system

Installation of the bus system is described below.

Thewiringisimplementedaslinewiring(see2.2)

orascentralwiring(see2.3).

2.1 General requirements

Fig. VIII: Illustration of line wiring and

Fig. XI: Central wiring

1. Shieldconnectionforthebuslines

2. Powersupplyconnection

3. Conductorsofthechargingcable

4. Connectionterminalsforbusconductors

5. Bus insulation

The following requirements must be met for any

typeofwiring:

• Alwaysuseascreenedbusline(e.g.CAT6a)for

the cabling.

• Donotexceedthetotalpermissibleeldbus

length of 500 m.

• PreparethebuscableandtheWallboxforinstal-

lation (Figs. VI and VII).

• Ensurethatthereissufcientdistancebetween

theconductors,thepowersupply(2),the

chargingcable(3)andthebuslines(5).

• Securelyconnectthebuslinestothedesignated

screen connections.

• Cutoffunusedindividualconductorsattheend

of the insulation.

2.2 Bus system in line wiring

Withlinewiring(Figs. VIII, IX and X), the bus

lineisrouteddirectlyfromaWallboxorexternal

Loading...

Loading...