Mark VII Restored Manual - V1.02 – Donated without cost to the world-wide Shopsmith Community - Everett L. Davis 2016 11

8. Adjust tilt-up stops. Unlock Trunnion on one end and tilt

machine unit to vertical on opposite end. Safety latch handles

should be pointing up.

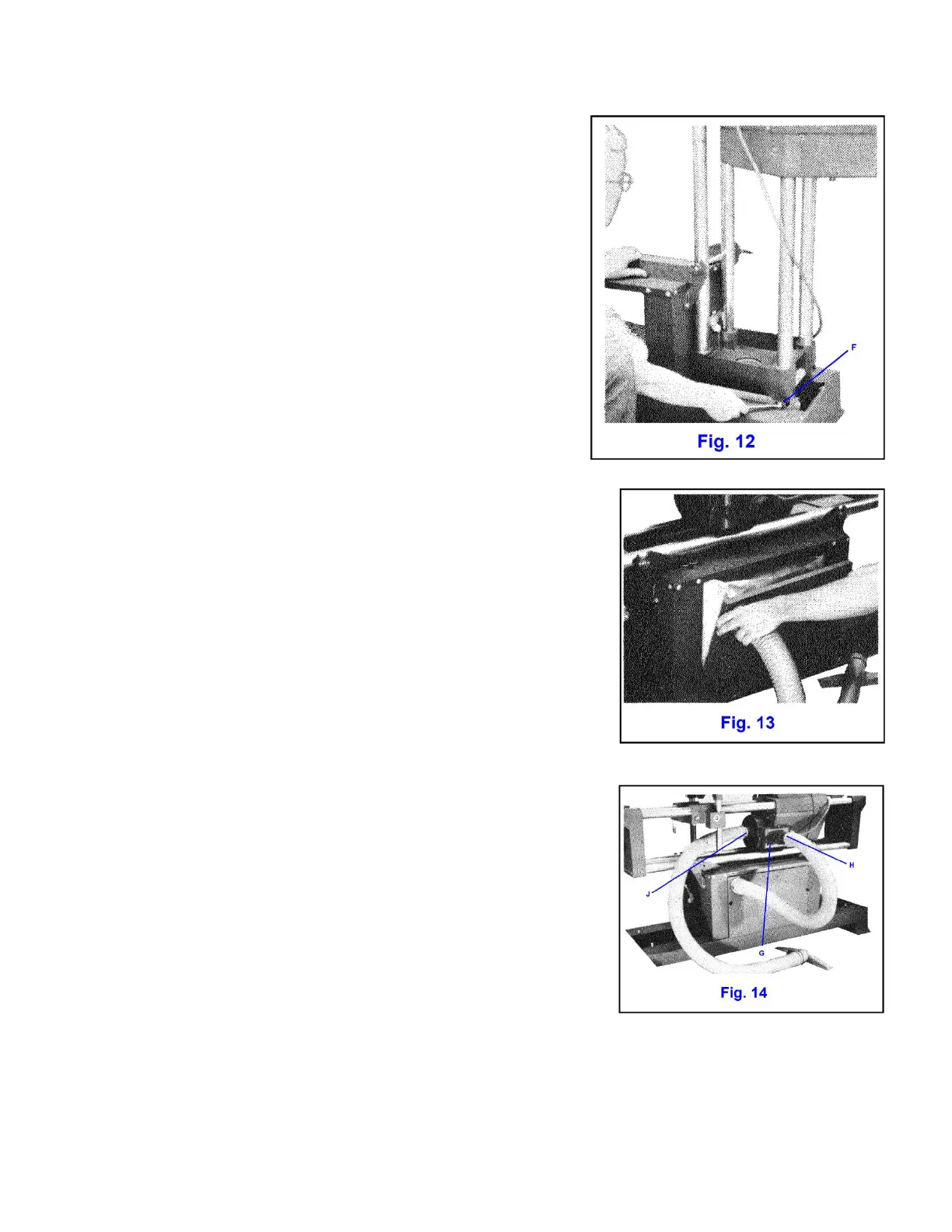

Adjust stop screws on top of rails ("F", Fig. 12) until bed tubes are

square with stand top. Use carpenter square and sight across

tubes. Tighten stop screw jam nuts. Safety latch should now

engage lower lip of end cap. Some springing of the end frame is

normal when engaging safety latch.

Return machine to horizontal and lock trunnion. Adjust stop

screws for other end in same manner.

9. Install front panel. Return machine to horizontal and install

front panel using #6 - 32 x 1 truss head screws and Tinnerman

nuts, one each in middle on each side.

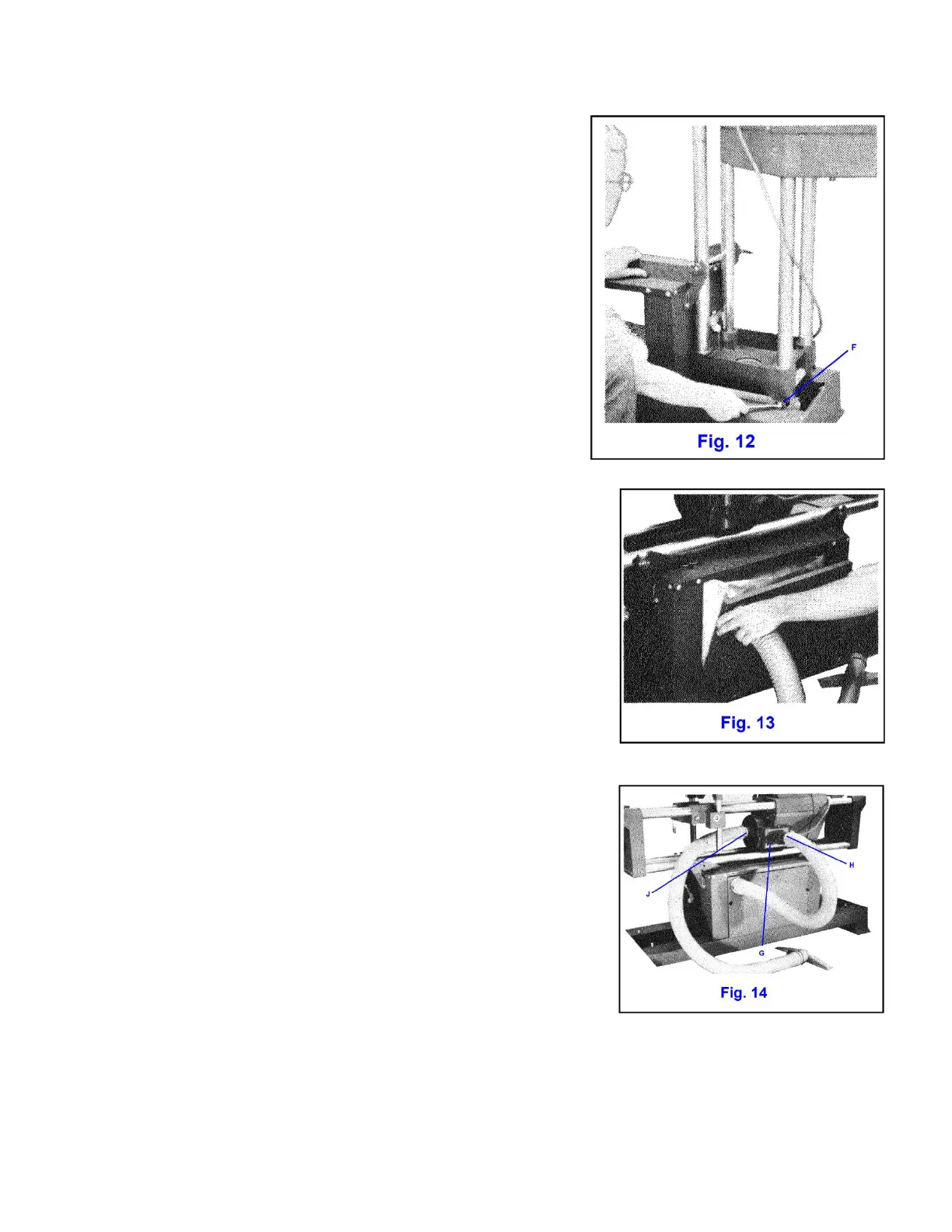

10. Install rear panel. Unfold sawdust vacuum bag and lay it on inside

of rear panel so that bag matches panel and inlet tube of bag lines up

with large flanged hole in panel. Tuck tube about one inch through

hole and spread it so that one end of the short hose can be inserted.

Make sure bag is still square with panel and secure it by pushing hose

adapter into panel hole, thereby sealing hose to bag tube. Mount rear

panel with hose at upper left corner, (Fig. 13) using the two #6 plastic

head thumb screws and Tinnerman nuts. Rest bottom of bag on rear

rail.

11. Connect discharge hose. Plug other end of hose into impeller

outlet duct opening ("G", Fig. 14). On some units the duct has two

outlets, one direct and one offset ("H"). The offset opening allows

vacuum to be used when carriage is next to headstock. Plug unused

hole with push-in plastic cap provided.

12. Connect vacuum hose. Plug long hose into impeller housing inlet

("J", Fig. 14) and your machine is ready to run.

BEFORE OPERATING YOUR SHOPSMITH MAKE THE ACCURACY CHECKS

WHICH FOLLOW IMMEDIATELY ON NEXT PAGE

Loading...

Loading...