Configuration

2.4 Procedure when engineering

1FT7 Synchronous Motors

50 Configuration Manual, (PFT7S) 01/2009, 6SN1197-0AD13-0BP2

J

M

Motor moment of inertia

J

G

Gearbox moment of inertia

J

load

Load moment of inertia

n

Load

Load speed

i Gear ratio

η

G

Gearbox efficiency

M

load

Load torque

M

R

Frictional torque

T Cycle time, clock cycle time

A; E Initial value, final value in time slice Δ

t

i

t

e

ON period

∆t

i

Time interval

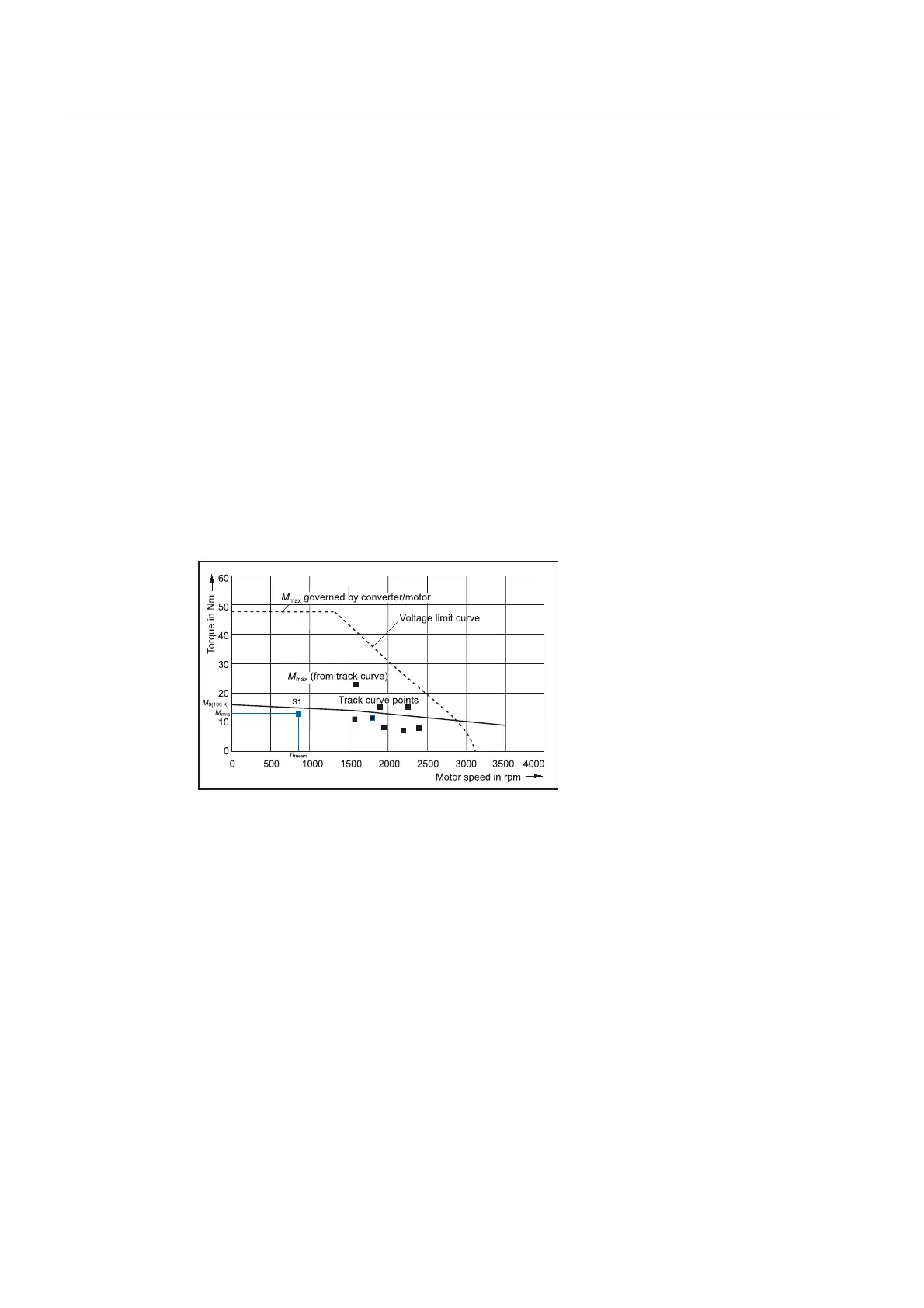

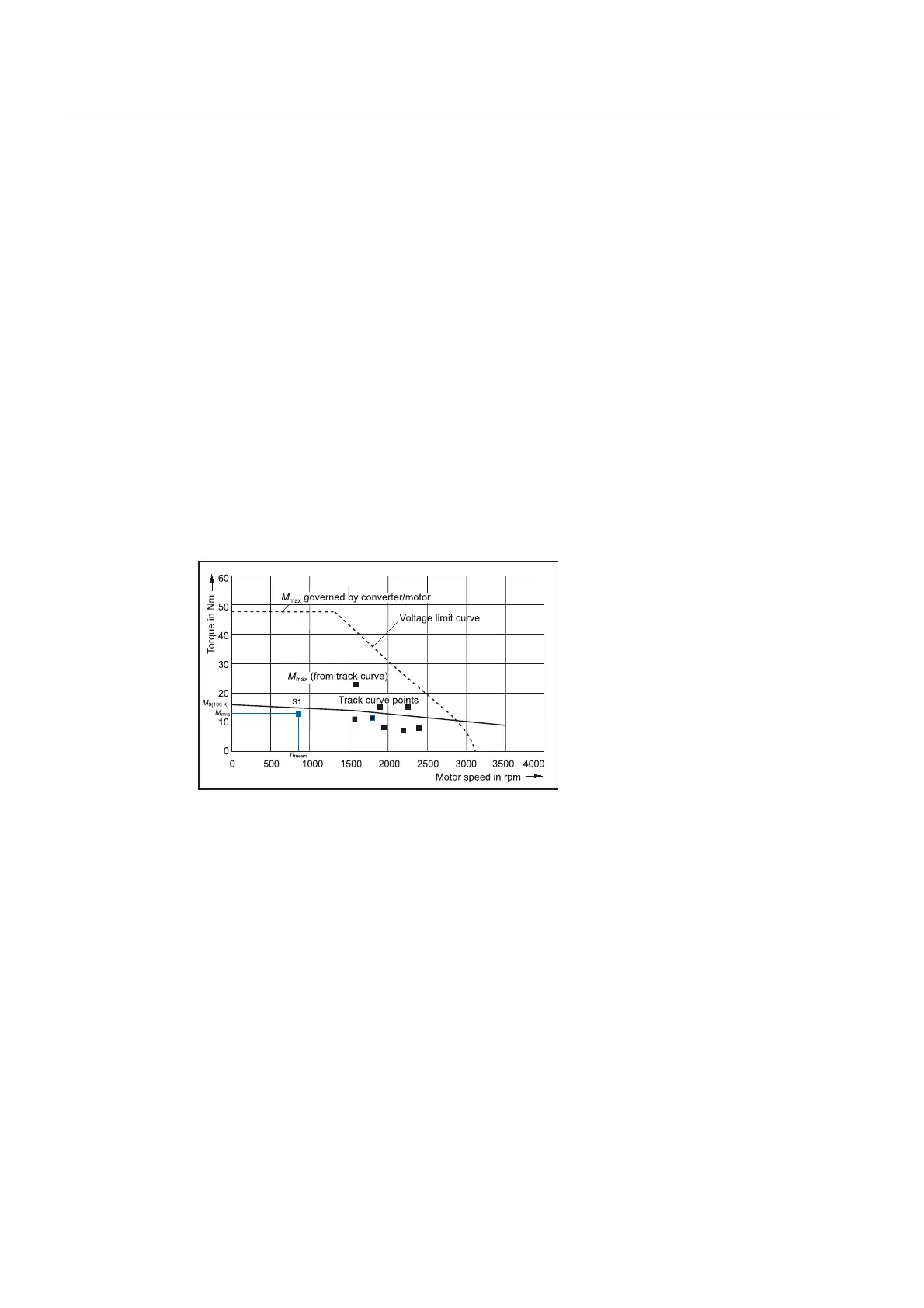

The RMS torque M

rms

must lie below the S1 curve.

The maximum torque M

max

is produced during the acceleration operation. M

max

must lie

below the voltage limiting characteristic curve. In summary, the motor is selected as follows:

Figure 2-7 Selecting motors depending on the load duty cycle (example)

Specification of the motor

Through variation, it is now possible to identify a motor which meets the requirements of the

application (duty cycle).

In a second step, a check is made as to whether the thermal limits are maintained. To do

this, the motor current at the base load must be calculated. The calculation depends on the

type of motor used (synchronous motor, induction motor) and the particular application (duty

cycle). When configuring according to duty cycle with constant ON period with overload, the

overload current must be calculated relative to the required overload torque.

Finally, the other motor features must be defined by configuring the motor options.

Loading...

Loading...