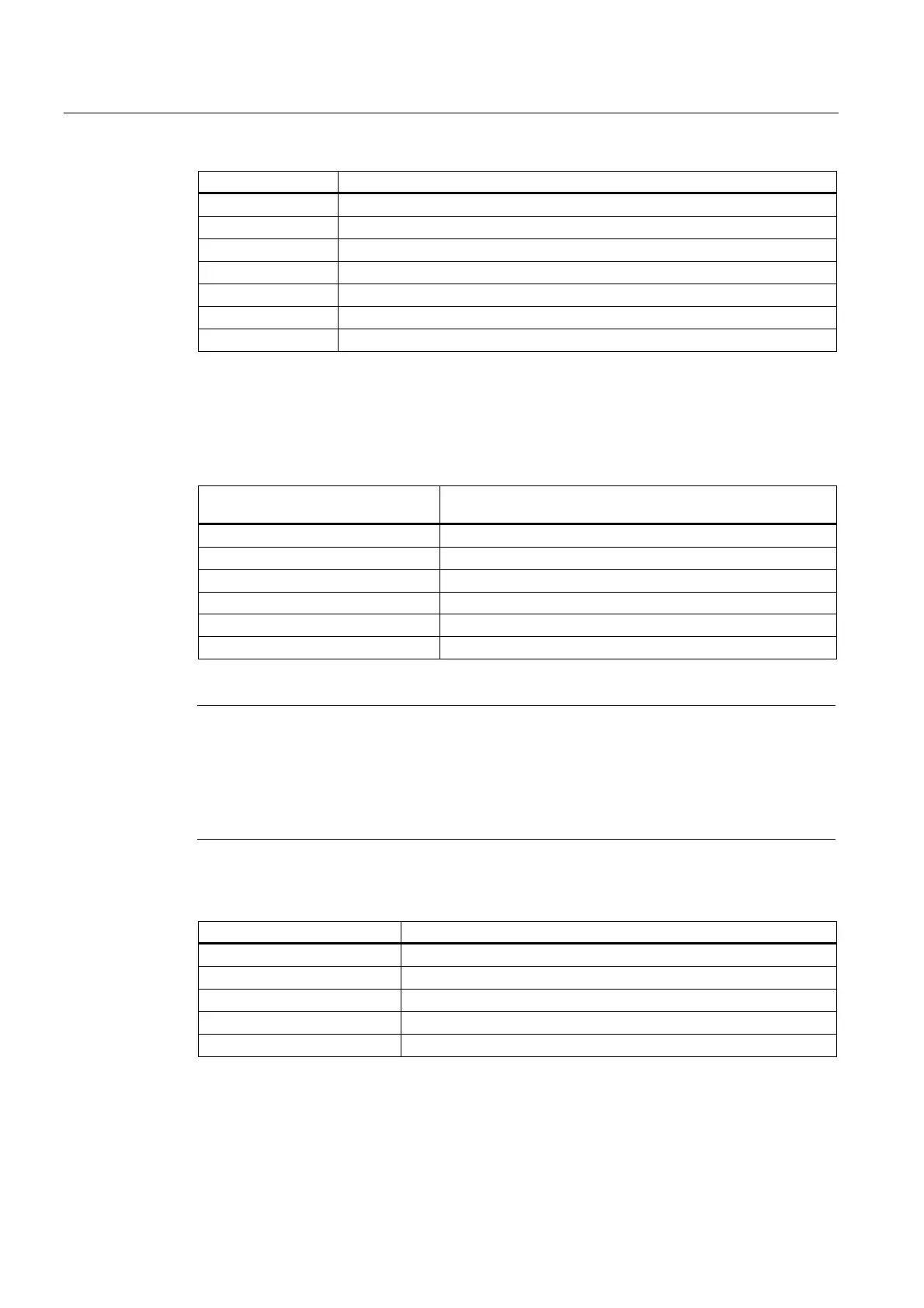

Mechanical properties of the motors

3.2 Liquid cooling

1FT7 Synchronous Motors

58 Configuration Manual, (PFT7S) 01/2009, 6SN1197-0AD13-0BP2

Motor type Cooling power to be dissipated [W]

1FT7102-5WH7 1400

1FT7105-5WC7 1200

1FT7105-5WF7 1600

1FT7105-5WH7 1900

1FT7108-5WC7 1500

1FT7108-5WF7 1800

1FT7108-5WH7 1900

3.2.3 Coolant

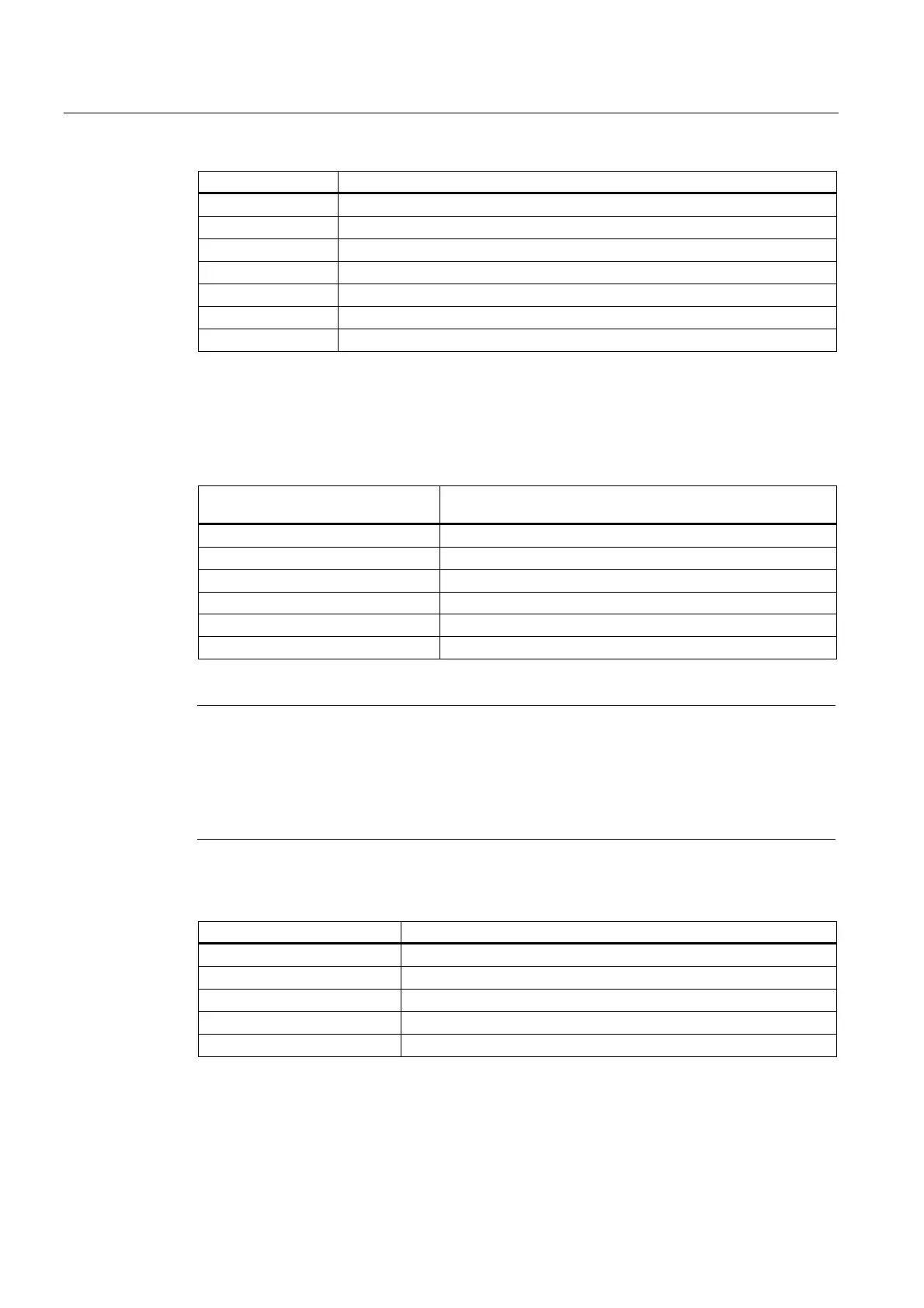

Table 3- 7 Water specifications for coolant

Quality of the water used as coolant for motors with

aluminum, stainless steel tubes + cast iron or steel jacket

Chloride ions < 40 ppm, can be achieved by adding deionized water.

Sulfate ions < 50 ppm

Nitrate ions < 50 ppm

pH value 6 ... 9 (for aluminum 6 ... 8)

Electrical conductivity < 500 μS/cm

Total hardness < 170 ppm

Note

It is recommended to use deionized water with reduced conductivity (5 ... 10 µS/cm) (if

required, ask the water utility for the values). According to 98/83/EC, drinking water may

contain up to 2500 ppm of chloride!

Manufacturers of chemical additives can provide support when analyzing the water that is

available on the plant side.

Table 3- 8 Coolant quality

Coolant quality

Cooling water According to the table "Water specifications for cooling water"

Corrosion protection 0.2 to 0.25 % inhibitor, Nalco TRAC100 (previously 0GE056)

Anti-freeze protection When required, 20 - 30 % Antifrogen N (from the Clariant Company)

Dissolved solids < 340 ppm

Size of particles in the coolant < 100 μm

Loading...

Loading...