Mechanical properties of the motors

3.2 Liquid cooling

1FT7 Synchronous Motors

Configuration Manual, (PFT7S) 01/2009, 6SN1197-0AD13-0BP2

53

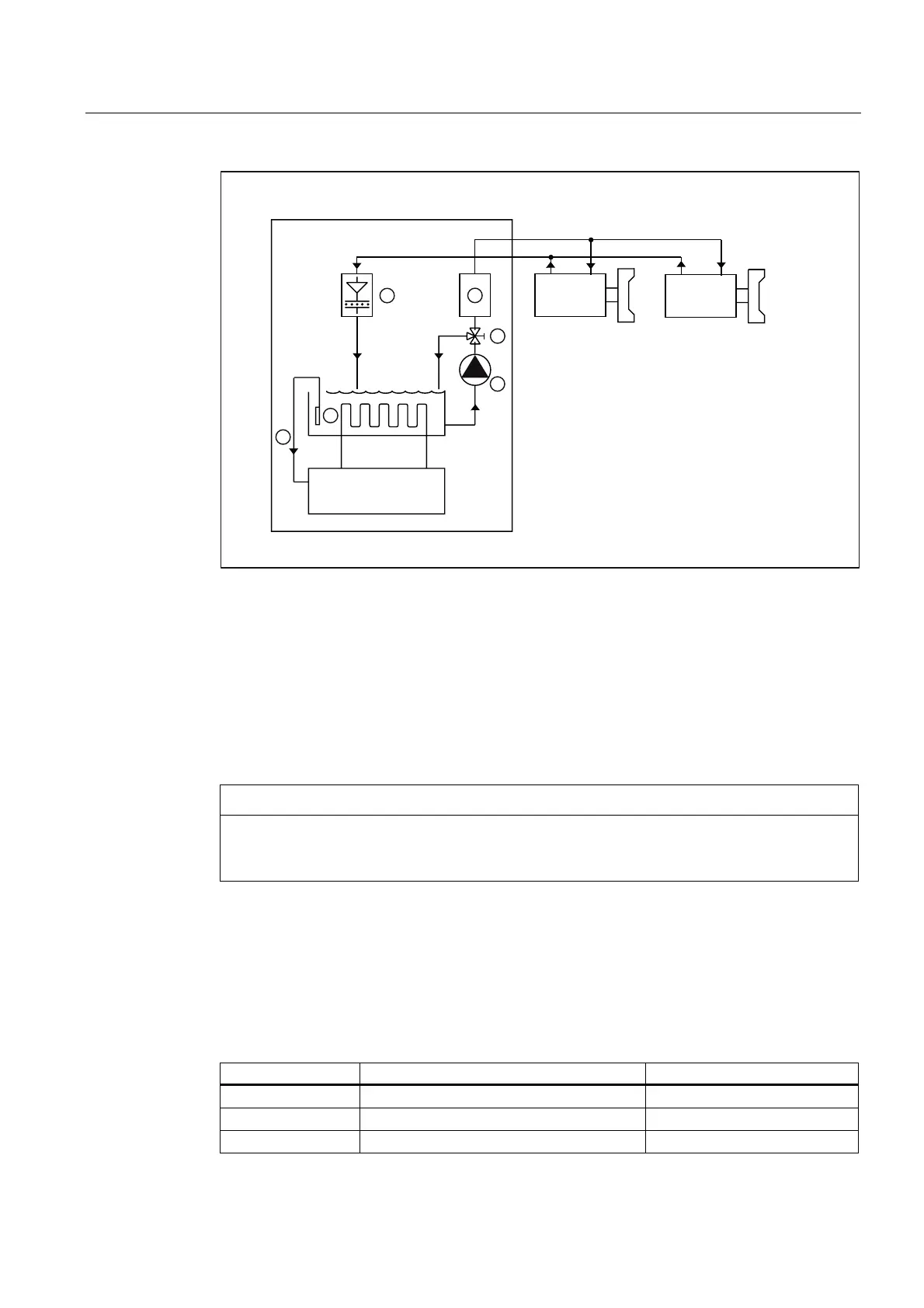

&RPSUHVVRUF

RROLQJXQLW

0RWRU

)LOWHU

)ORZPHWHU

3UHVVXUHUHOLHIYDOYHVHWWLQJYDOYHIORZTXDQWLW\

3XPS

&RROLQJZDWHUWDQN

7HPSHUDWXUHVHQVLQJFRROLQJZDWHU

7KHVHFRPSRQHQWVDUHQRWDEVROXWHO\QHFHVVDU\

&RROLQJXQLW

0RWRU

Figure 3-1 Example of a semi-open cooling circuit

Equipotential bonding

All components in the cooling system (motor, heat exchanger, piping system, pump,

pressure equalization tank, etc.) must be connected to an equipotential bonding system. This

is implemented using a copper bar or finely stranded copper cable with the appropriate cable

cross-sections.

NOTICE

Under no circumstances may the coolant pipes come into contact with live components.

There must always be an isolating clearance of > 13 mm! The pipes must be securely

mounted and checked for leaks.

Materials used in the motor cooling circuit

The materials used in the cooling circuit must be coordinated with the materials in the motor.

Table 3- 2 Materials used in the motor cooling circuit

Shaft height Bearing shield Pipes in the stator

1FT706x Cast iron (EN-GJL-200) Stainless steel

1FT708x Cast iron (EN-GJL-200) Stainless steel

1FT710x Cast iron (EN-GJL-200) Stainless steel

Loading...

Loading...