Mechanical properties of the motors

3.2 Liquid cooling

1FT7 Synchronous Motors

56 Configuration Manual, (PFT7S) 01/2009, 6SN1197-0AD13-0BP2

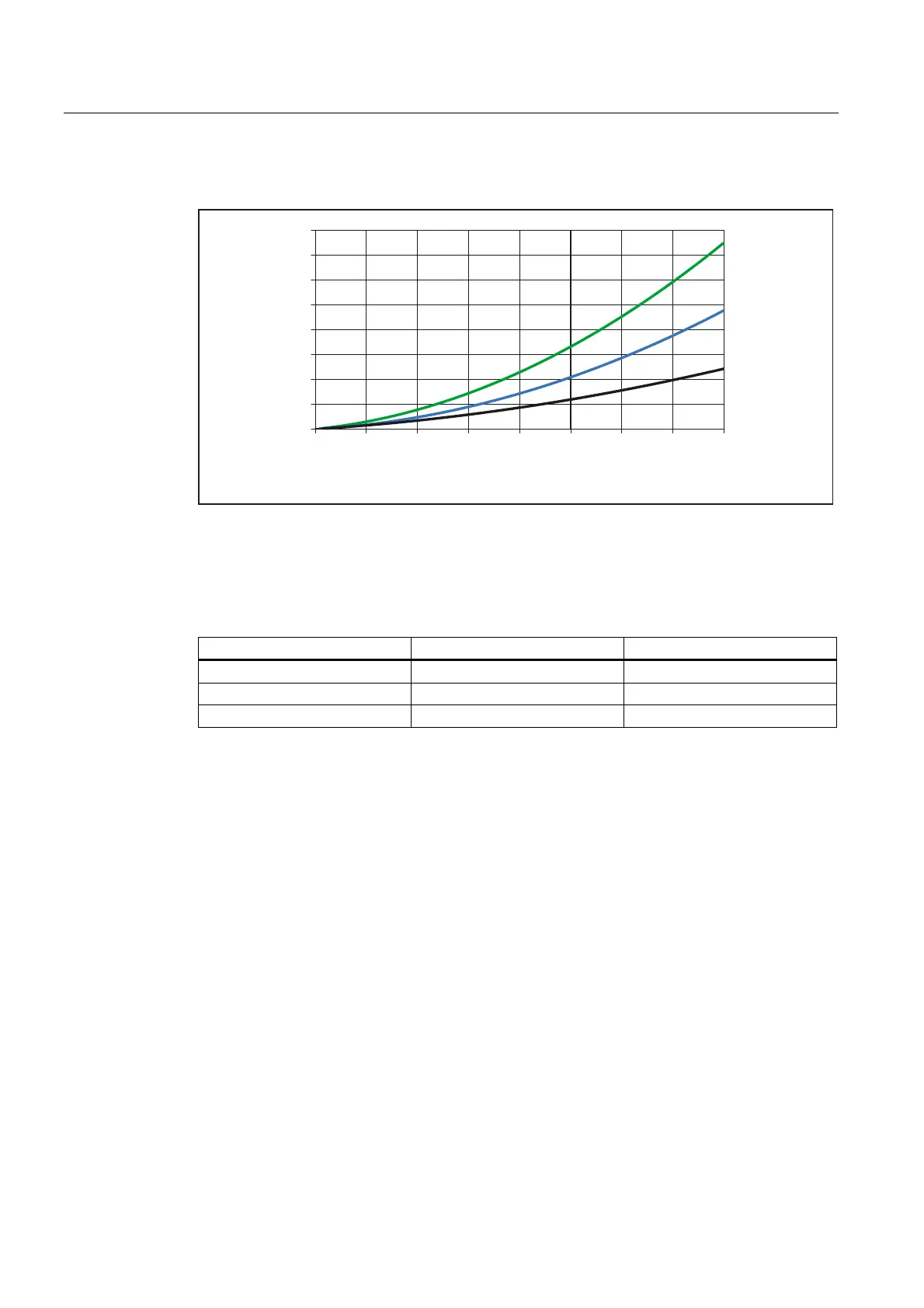

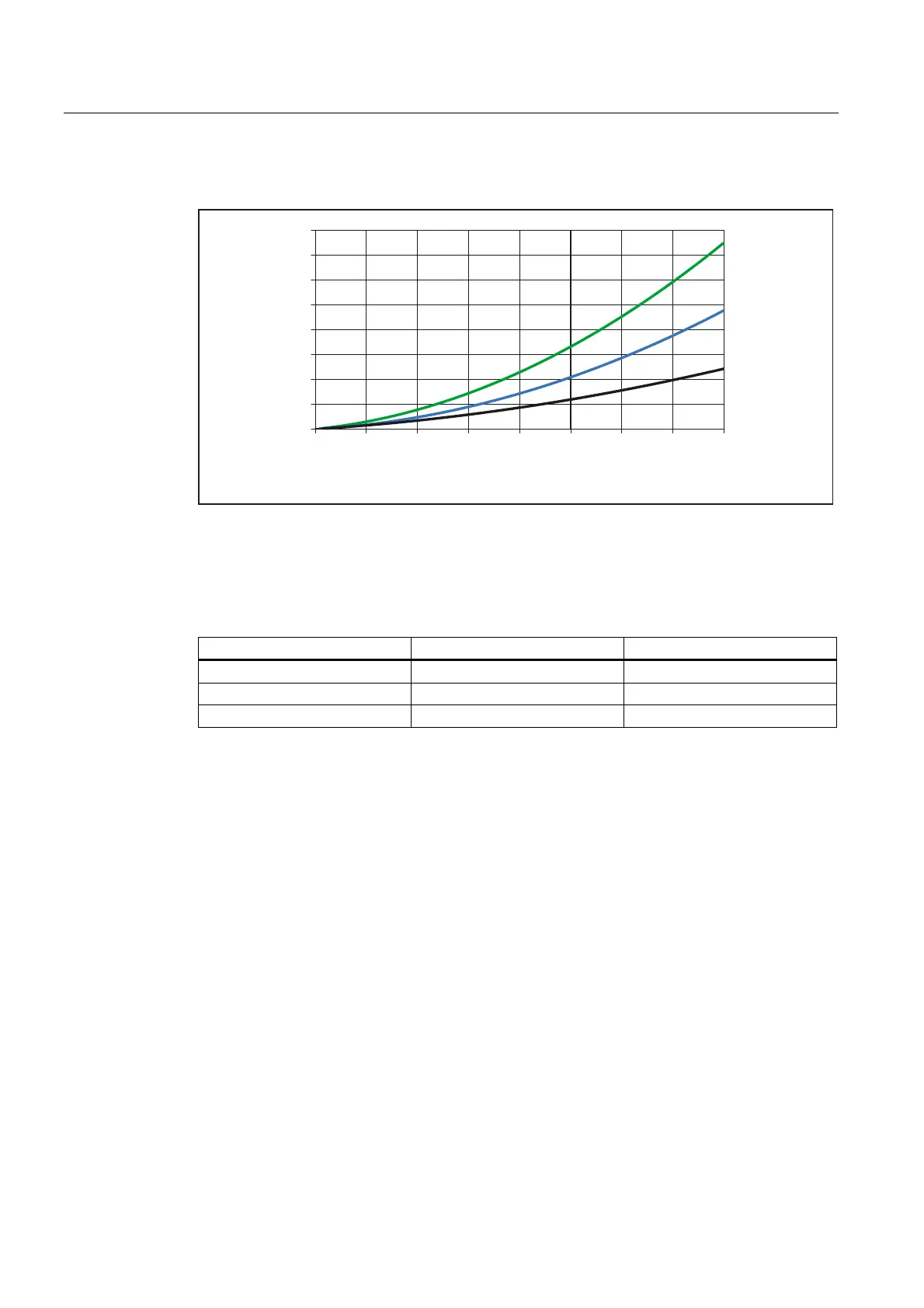

Pressure loss in the motor

)7[

)7[

)7[

'XUFKIOXVVPHQJH>OPLQ@

)ORZUDWH>OPLQ@

'UXFNDEIDOO>03D@

'HFUHDVHLQSUHVVXUH>DWP@

Figure 3-2 Pressure loss 1FT7

The nominal coolant flows specified in the following table must be maintained in order to

ensure sufficient cooling.

Table 3- 4 Pressure loss at the nominal coolant flow

Shaft height Flow rate Pressure loss

1FT706x 3 l/min 0.03 MPa

1FT708x 4 l/min 0.03 MPa

1FT710x 5 l/min 0.025 MPa

Pressure balancing

If various components are connected in the cooling circuit, pressure balancing may be

necessary. Reactor elements must be fitted at the coolant outlet for the motor or the relevant

components.

Avoiding cavitation

During uninterrupted duty, the pressure drop by an inverter or motor must not exceed

0.2 MPa. Otherwise the high volumetric flow will lead to cavitation or abrasion damage.

Connecting motors in series

For the following reasons, connecting motors in series is only recommended under certain

conditions:

● The necessary volumetric flows of the motors must be within a similar order of magnitude

(< factor 2)

● The temperature rise in the coolant can lead to derating in the second or third motor if the

maximum coolant intake temperature is exceeded.

Loading...

Loading...