Maintenance

7.1 Maintenance

A5E00215731A AD

Siemens AG Operating Instructions 2.02 1PL618

51

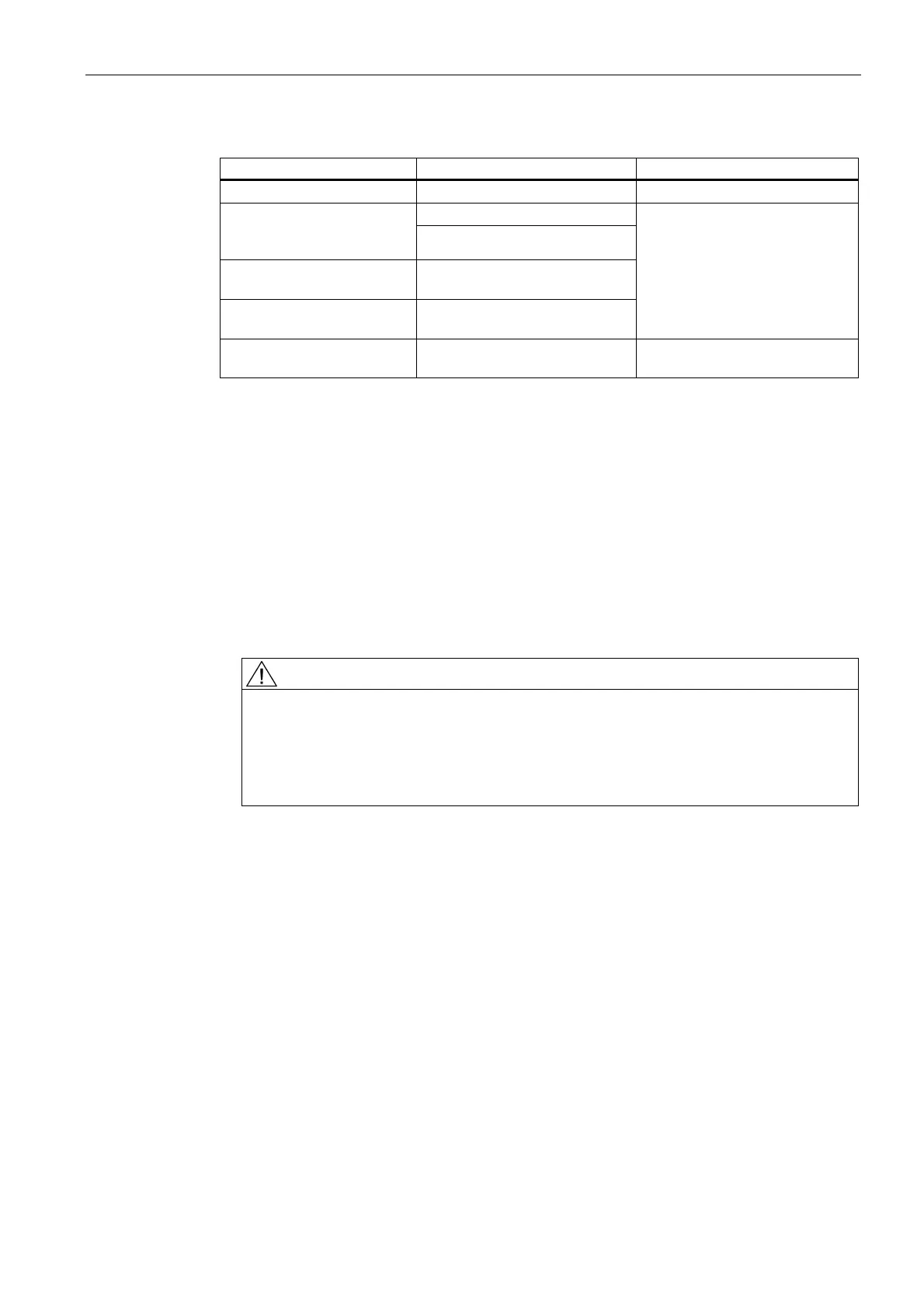

Table 7-1 Operating period intervals

Measures Operating period intervals Intervals

Initial inspection After 500 operating hours after 6 months at the latest

Belt operation 12 000 h Continuous lubrication

(Machines without regreasing

device )

Coupling operation 20 000 h

Machines with regreasing

device (option)

(see lubrication instruction plate)

Clean depending on local degree of

pollution

General inspection Approximately every 16000

operating hours

After 2 years at the latest

[ID: 356]

7.1.3 Maintenance of the external fan

Procedure

● Check the external fan VDI 2056 annually for mechanical vibrations. The maximum

permissible vibrational severity is 2.8 mm/s measured on the end shield of the impeller-

side motor bearing.

● Regularly clean and inspect the fan. Impeller and frame are subject to natural wear

depending on the area of application and displacement medium.

WARNING

Impeller can crack

Due to deposits and the resulting imbalance there is a hazard of fatigue fracture of the

impeller. The impeller can crack in operation. Death, serious injury, or material damage

can result.

Regularly clean and inspect the fan.

● Refer to the maintenance and service information provided by the manufacturer of the

external fan.

7.1.4 Bearings

Description

The three-phase motors have grease-lubricated, rolling-contact bearings. A regreasing

device is optional.

A deep-groove ball bearing is installed at the NDE as a locating bearing. Depending on the

type of load, a deep-groove ball bearing or cylindrical-roller bearing is installed at the DE as

a floating bearing.

Loading...

Loading...