Maintenance

7.3 Corrective Maintenance

A5E00215731A AD

62 Siemens AG Operating Instructions 2.02 1PL618

Installing the active parts of the bearings

NOTICE

Before mounting the bearings, ensure that the parts and components that are to be located

on the shaft inside the bearing have been mounted beforehand!

To fit the bearings on the shaft, heat them up to about 80°C in oil or air.

Then push the bearings onto the shaft up to its shoulder.

NOTICE

Avoid any heavy blows that might damage the bearings.

Fill the bearings with specified grease (see section entitled "Types of grease") until it is flush.

Also observe the following installation condition:

● If rotary shaft seals without helical springs are installed, the replacement part must also

be installed without a spring.

[ID: 378.01]

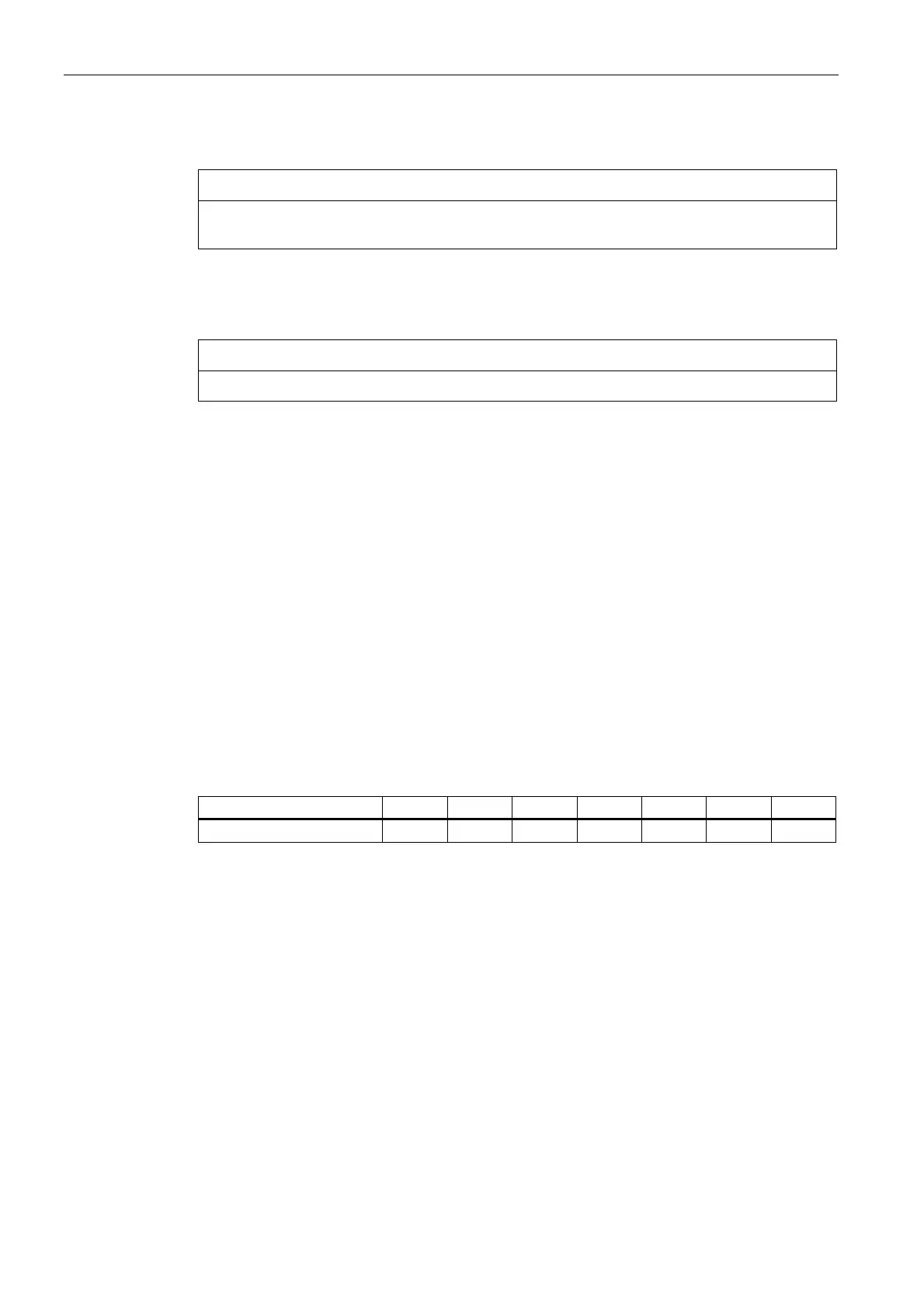

7.3.4 Screw-type connections

Tightening torque for screwed union connections

The screwed union connections with metal contact surfaces (end shields, active bearing

parts, terminal box parts bolted onto the stator frame) should be tightened to the following

torque with a tolerance of ± 10 %, depending on the thread size.

Table 7-3 Tightening torque for screwed union connections

Thread size M6 M8 M10 M12 M16 M20 M24

Tightening torque [Nm] 8 20 40 70 170 340 600

Please refer to the relevant sections and drawings for all other tightening torques (electrical

connections and bolted connections for parts with flat gaskets).

Bolt locking devices

Nuts or bolts that are mounted together with locking, resilient and/or force-distributing

elements (e.g., safety plates, spring-lock washers, etc.) must be refitted together with

identical, fully functional elements.

Always replace keyed elements.

[ID: 379.01]

Loading...

Loading...