Using the Command Interface

69

DP/AS-Interface Link 20E

Release 11/2002

C79000-G8976-C138–04

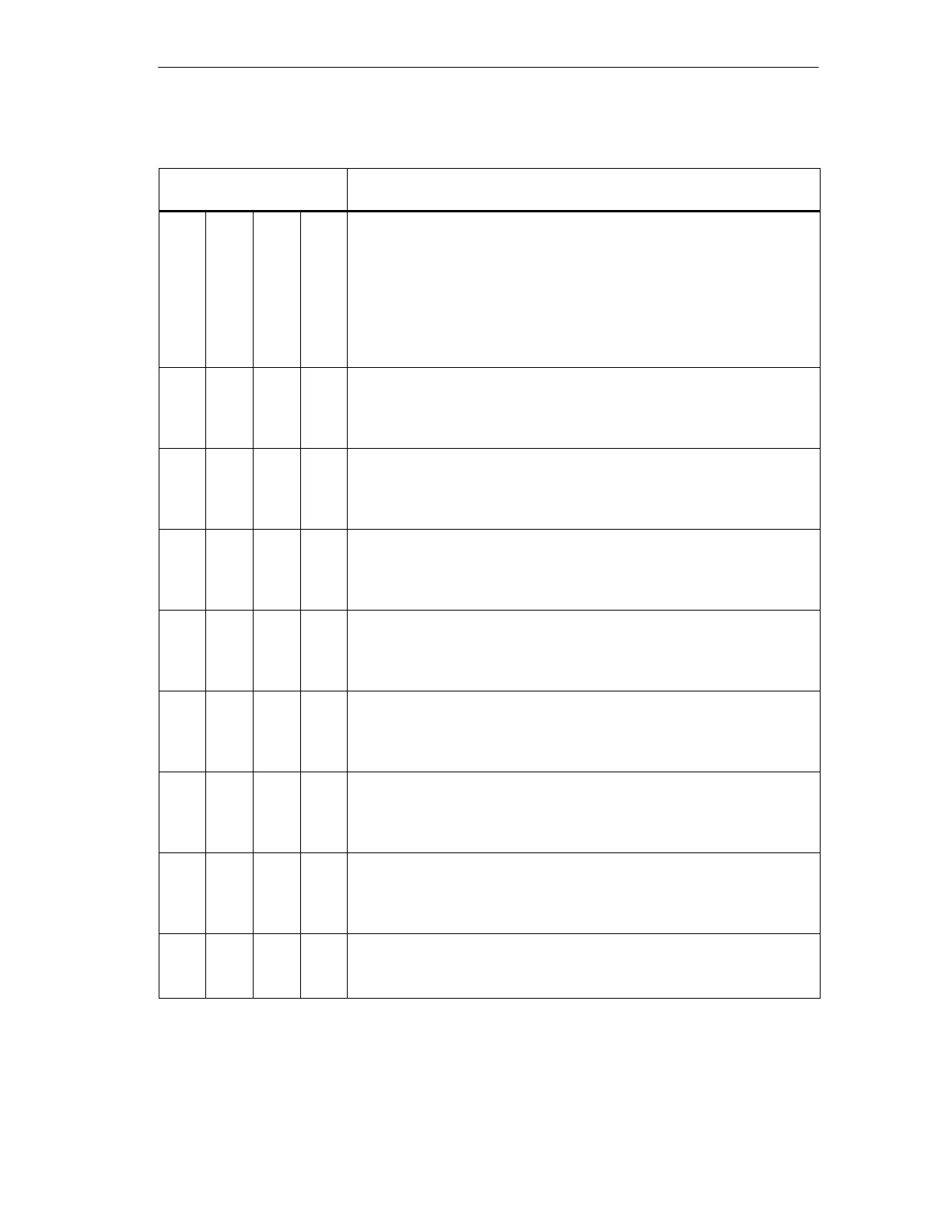

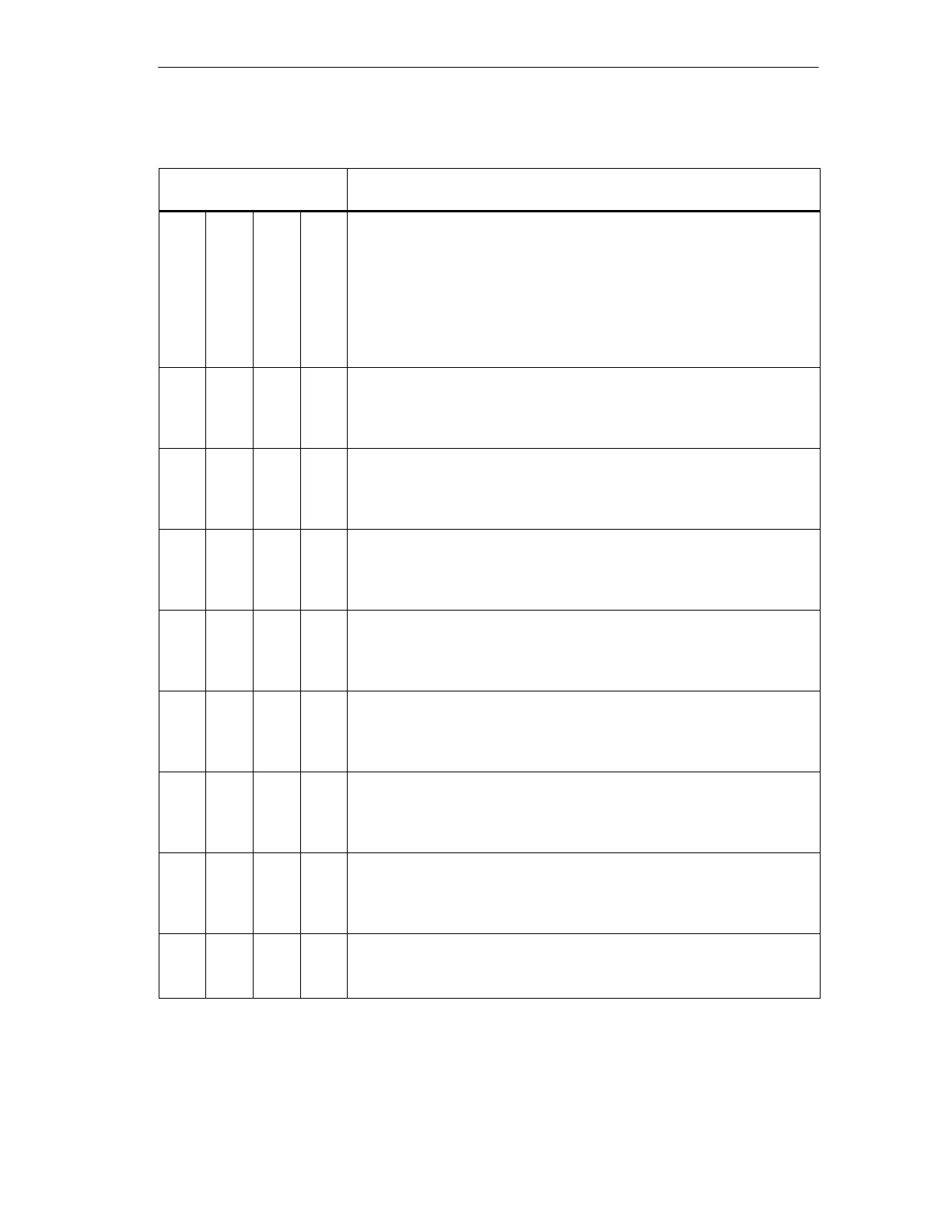

Table 3-1 Coding of the Status Nibble, continued

Status nibble (1st byte of

the digital input data)

Meaning

0 0 0 1 Command processing is completed. With an asynchronous read job, a

2-byte return value can be fetched by the AS-i master. Two situations

must be distinguished:

The return value is 0: A command without response data was completed

without error

The return value is a value not equal to 0: The command was terminated

with error.(See Table 3-3)

A new command can be triggered by the user program

0 0 1 1 Command processing was completed without error. Using an

asynchronous read job, 1 byte of response data can be fetched by the

AS-i master.

A new command can be triggered by the user program

0 1 0 1 Command processing was completed without error. Using an

asynchronous read job, 4 bytes of response data can be fetched by the

AS-i master.

A new command can be triggered by the user program

0 1 1 1 Command processing was completed without error. Using an

asynchronous read job, 14 bytes of response data can be fetched by the

AS-i master.

A new command can be triggered by the user program

1 0 0 1 Command processing was completed without error. Using an

asynchronous read job, 16 bytes of response data can be fetched by the

AS-i master.

A new command can be triggered by the user program

1 0 1 1 Command processing was completed without error. Using an

asynchronous read job, 32 bytes of response data can be fetched by the

AS-i master.

A new command can be triggered by the user program

1 1 0 1 Command processing was completed without error. Using an

asynchronous read job, 56 bytes of response data can be fetched by the

AS-i master.

A new command can be triggered by the user program

1 1 1 1 Command processing was completed without error. Using an

asynchronous read job, 221 bytes of response data can be fetched by the

AS-i master.

A new command can be triggered by the user program

0 1 0 0 Job processing is completed. The response data or the return value of the

previous job have already been read by the user.

A new command can be triggered by the user program

Loading...

Loading...