Commissioning and operation

5.2 Using the application

Safety engineering with AS‑Interface in the SIMATIC ET 200SP, including typical circuit diagram

Function Manual, 08/2020, A5E44991382002A/RS-AB/002

53

5.2 Using the application

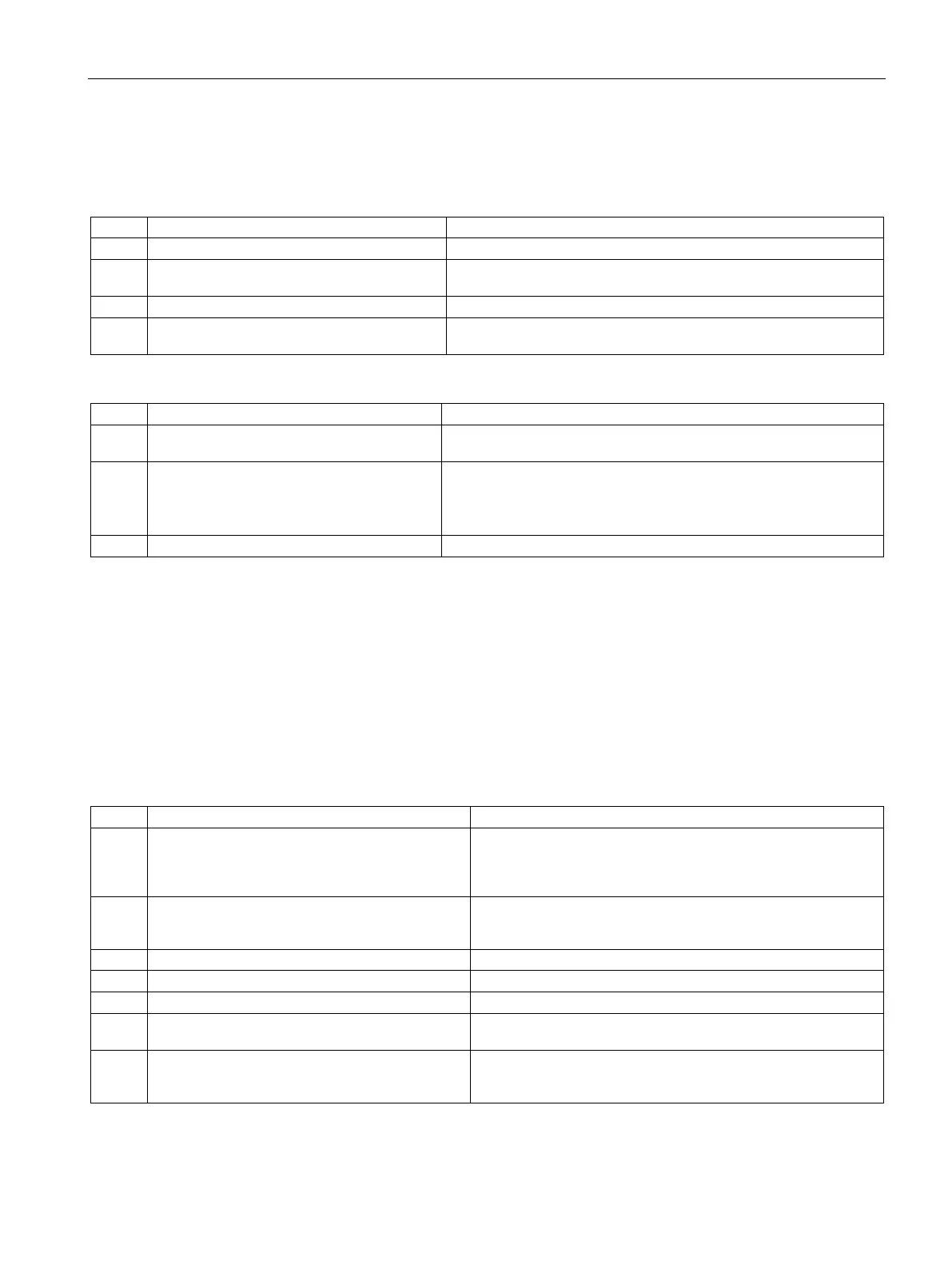

Starting a machine

Close the protective door.

Move the toggle switch into the position that

locks the protective door.

The voltage in the solenoid is switched off and the locking

mechanism moves into the actuator. The protective door is locked.

Unlock the emergency stop button.

Press the start pushbutton.

After the emergency stop button has been unlocked,

acknowledgment is required. The machine starts.

Unlock and open the protective door

Move the toggle switch into the position

that unlocks the protective door.

The machine switches off and runs down.

Wait for the parameterized delay time

before unlocking the protective door.

In this example: 5 seconds

After the time has expired, the solenoid is supplied with power, and

moves the locking mechanism out of the actuator. The protective

Open the protective door.

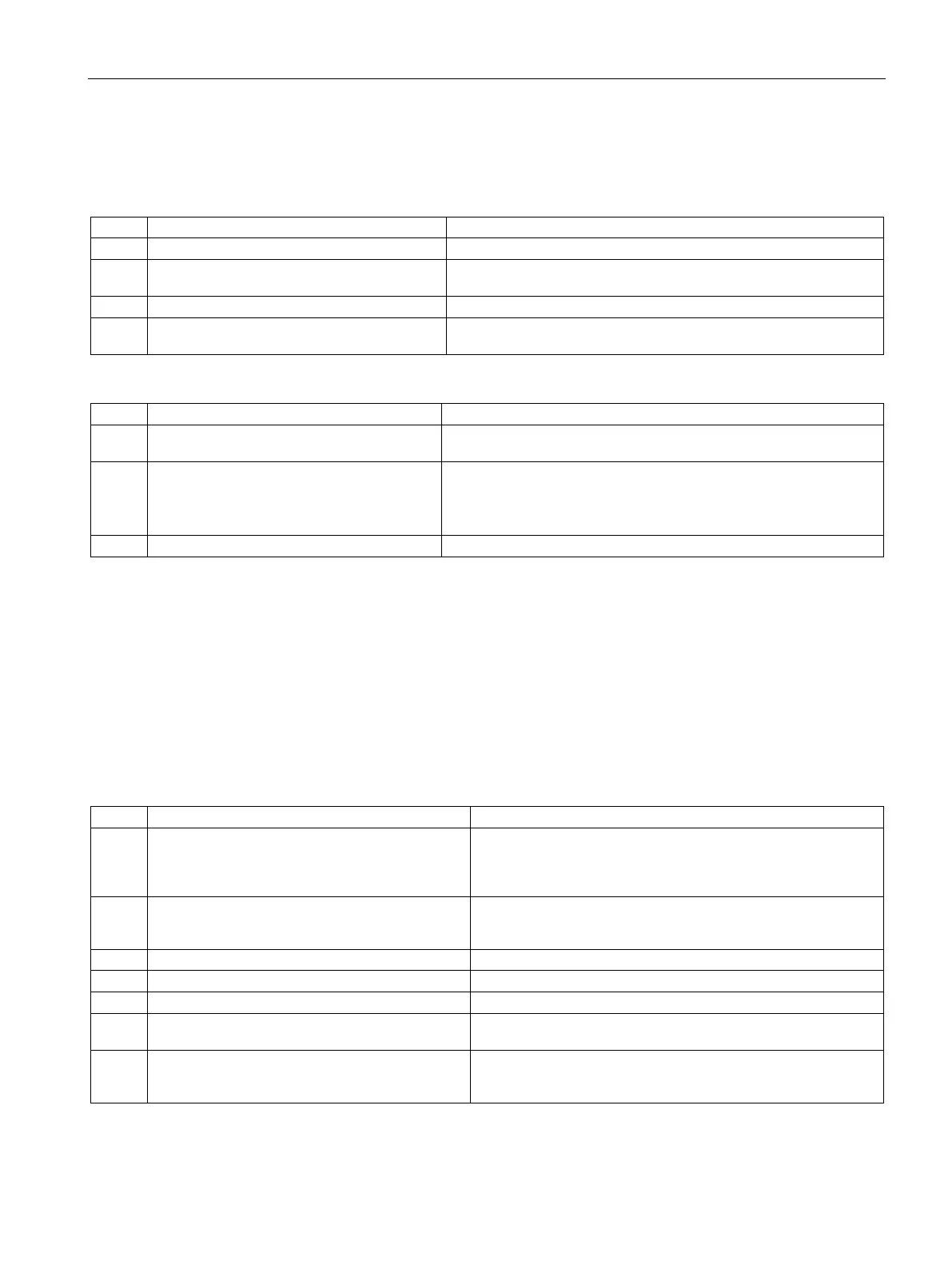

Acknowledging other faults in the safety function

If another fault occurs in the safety function, the machine is immediately switched off and a

restart is prevented. Proceed as follows to acknowledge the fault.

Possible faults that are acknowledged in this way include:

• Cross circuit between the two emergency stop channels.

• External voltage on the fail-safe outputs

• Withdrawing a fail-safe module

• Contact welding of a contactor

Check the LEDs on the fail-safe modules. If one

red LED illuminates, a fault in the hardware has

been detected. Search for the fault by means of

the online diagnostics in the TIA Portal.

If all LEDs are green, the safety program has

detected a fault. Look at the variable table to

The #fault and #ackReg variables of the

ProtDoorWithInterlocking block instructions can help with the

Close the protective door.

Unlock the emergency stop button.

Move the toggle switch to lock the protective

door.

The voltage in the solenoid is switched off and the locking

mechanism moves into the actuator.

Press the start pushbutton.

Passivated channels of the fail-safe modules are re-integrated.

Faults detected by the safety program are acknowledged. The

Loading...

Loading...