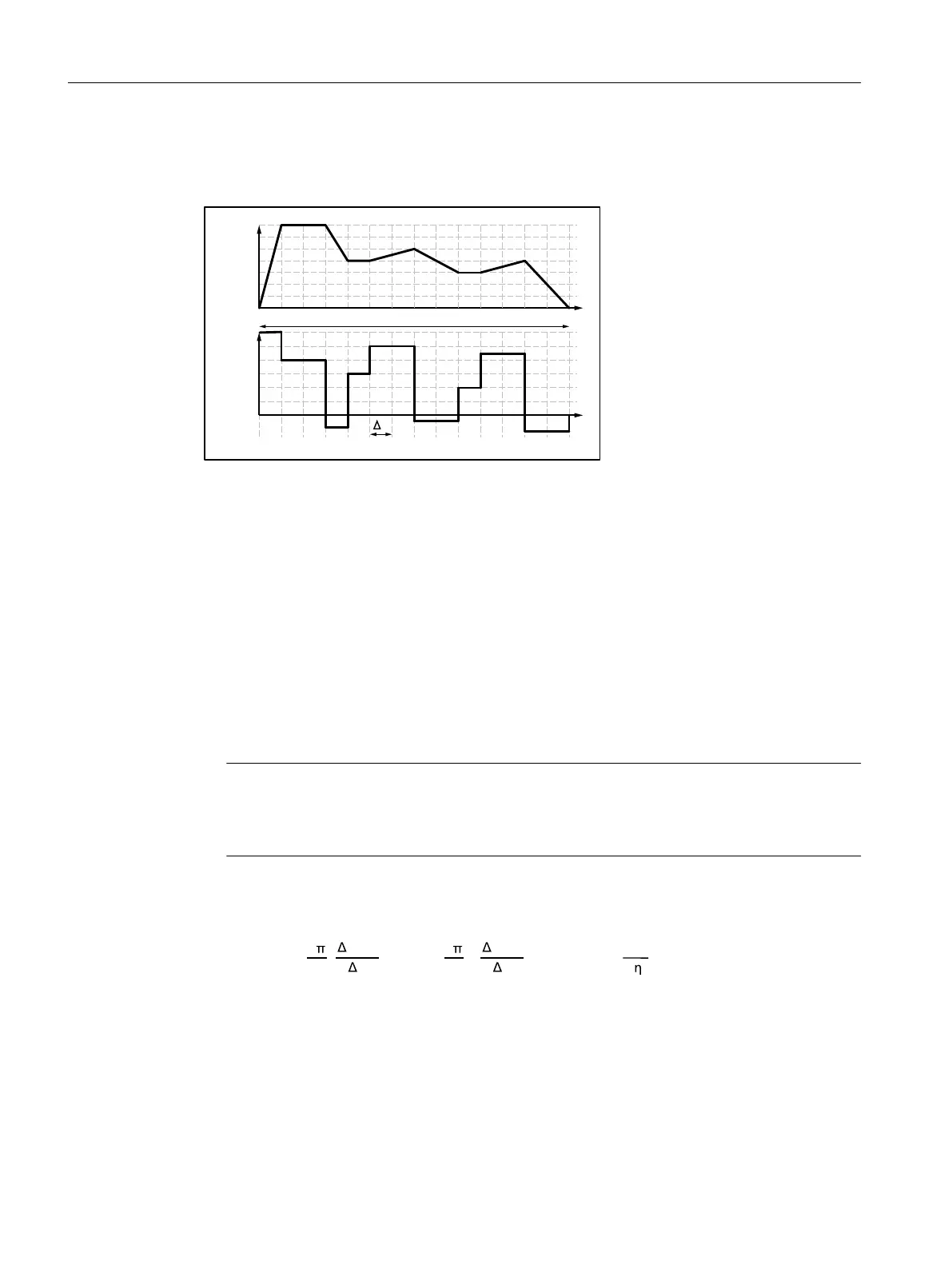

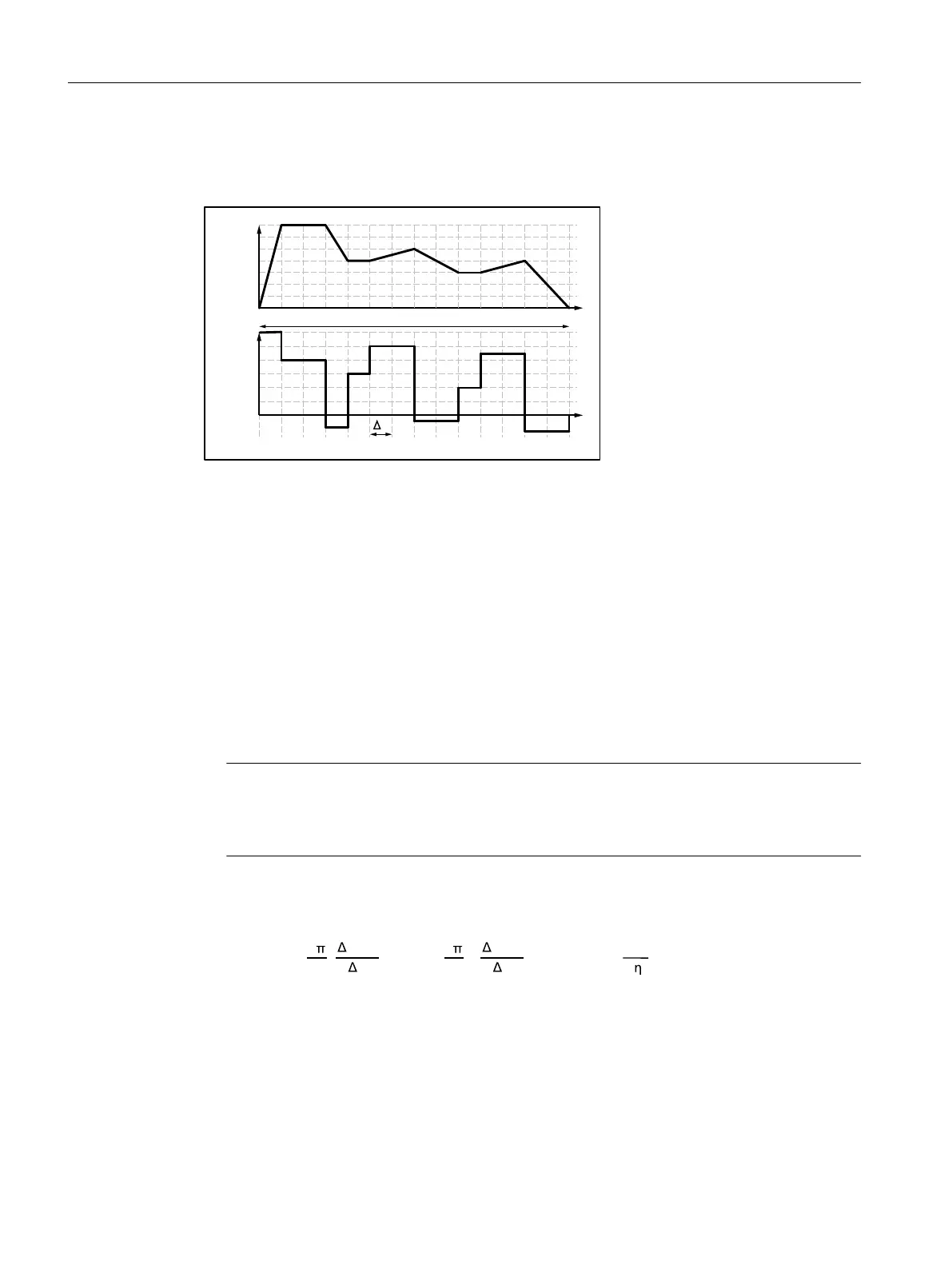

Free duty cycle

A free duty cycle denes the curve of the motor speed and the torque over time.

n Speed T Cycle time

M Torque Δt

i

Time interval

t Time

Figure 5-4 Example of free duty cycle

Procedure

Determine the required motor torque as follows:

• Dene a load torque for each time slice. Also take the average load moment of inertia and

motor moment of inertia into account for acceleration operations. If required, take a

frictional torque into account that opposes the direction of motion.

• With mounted gearbox:

Determine the load torque and the acceleration torque that must be supplied by the motor.

Take the gear ratio and gear eciency into account.

Note

A higher gear ratio increases positioning accuracy in terms of encoder resolution. For any

given encoder resolution, as the gear ratio increases, so does the resolution of the machine

position to be detected.

The following formulas can be used for duty cycles outside the eld weakening range.

For the motor torque in a time slice Δt

i

the following applies:

WR0L

0

*

WV/DL

L

WV/D

W

s

/DL

L

t

V/DL

5

*

M J J

n

t

i J

n

t

M M

i

=

+ •

2

06

• • +

(

•

2

06

• + +

)

•

1

•

)(

The motor speed is:

Conguration

5.2 Conguring procedure

1FK2 Synchronous Motors for SINAMICS S120

70 Conguration Manual, 02/2022, A5E46927724B AD

Loading...

Loading...