Configuration

5.2 Procedure when engineering

S-1FT7 synchronous motors

Configuration Manual, 09/2018, A5E45099423B AA

115

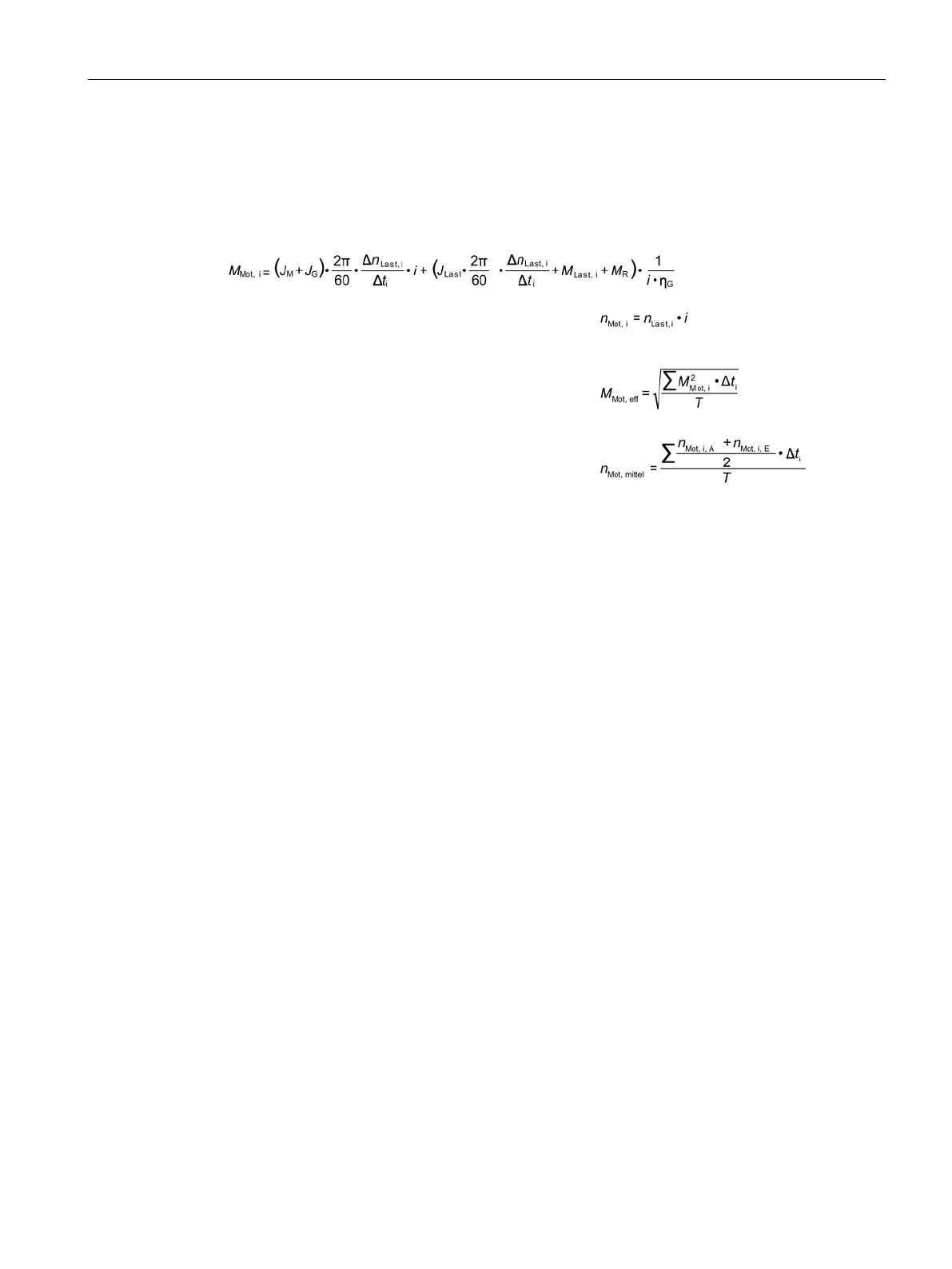

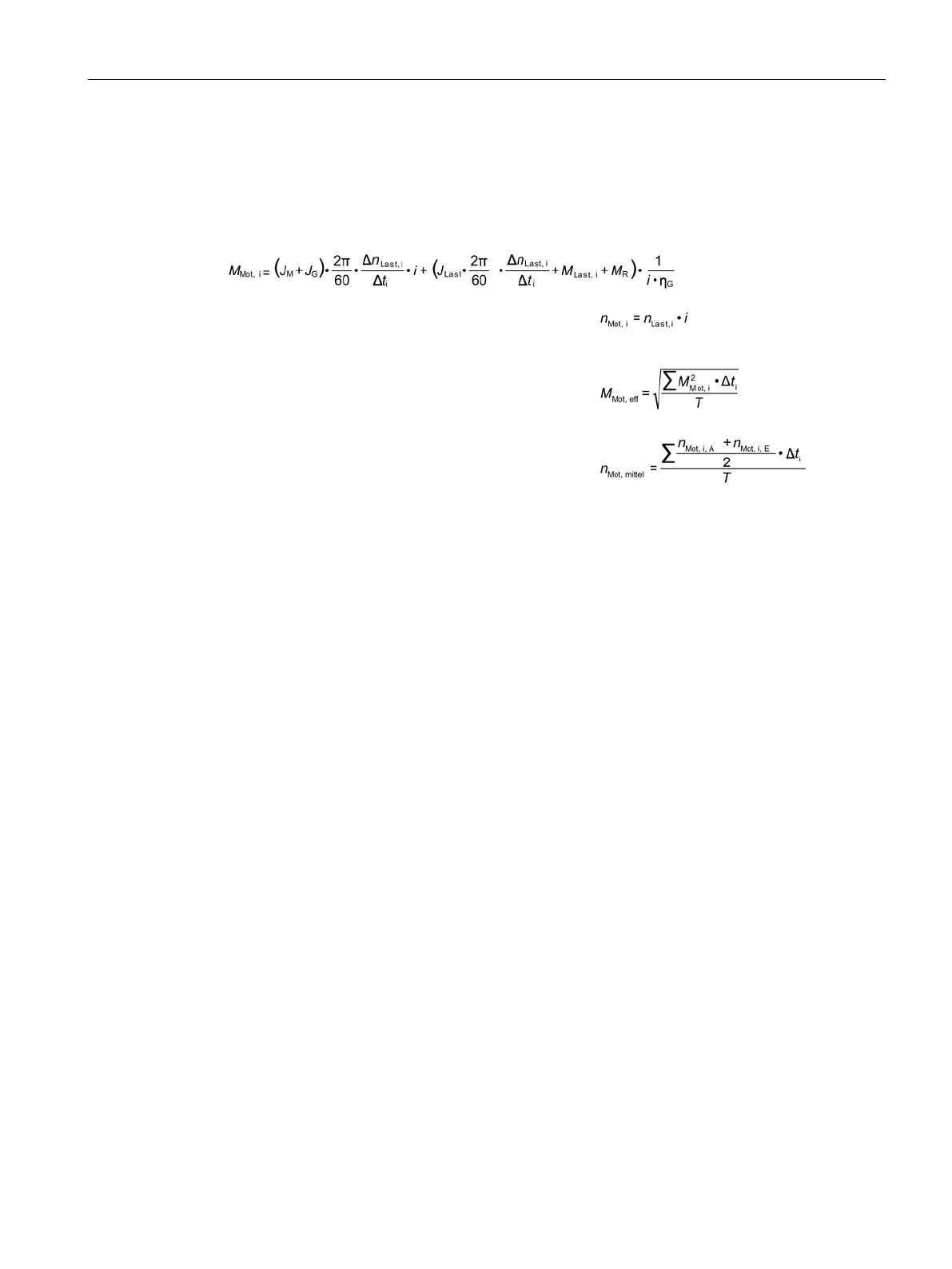

The following formulas can be used for duty cycles outside the field weakening range. For

duty cycles in the field weakening range, the drive system must be configured using the

SIZER configuration tool.

For the motor torque in a time slice Δ

t

i

the following applies:

e torque is obtained as follows:

The average motor speed is calculated as follows:

G

Gearbox moment of inertia

load

load

load

R

Initial value, final value in time slice Δ

t

i

i

The effective torque M

eff

must lie below the S1 characteristic curve.

The maximum torque M

max

is produced during the acceleration operation. M

max

must lie

below the voltage limiting characteristic curve. In summary, the motor is configured as

follows:

Loading...

Loading...