Mechanical properties

3.1 Cooling

S-1FT7 synchronous motors

42 Configuration Manual, 09/2018, A5E45099423B AA

Materials and components in the cooling circuit

Note

Minimizing electrochemical processes in the cooling circuit

The electrochemical processes that take place in a cooling system must be minimized by

choosing the right materials.

Avoid combinations of different materials, such as copper, brass, iron, or halogenated plastic

(PVC hoses and seals).

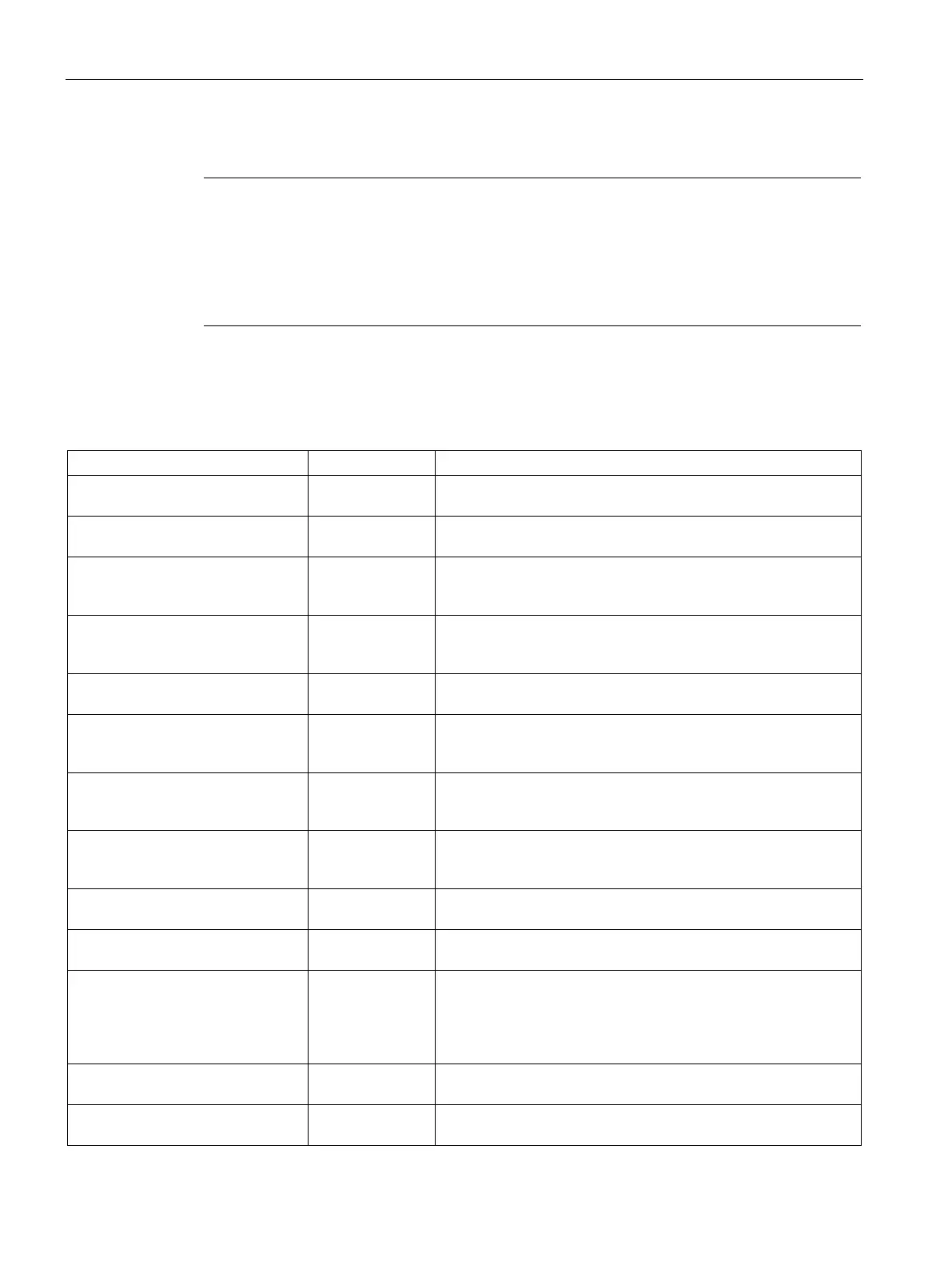

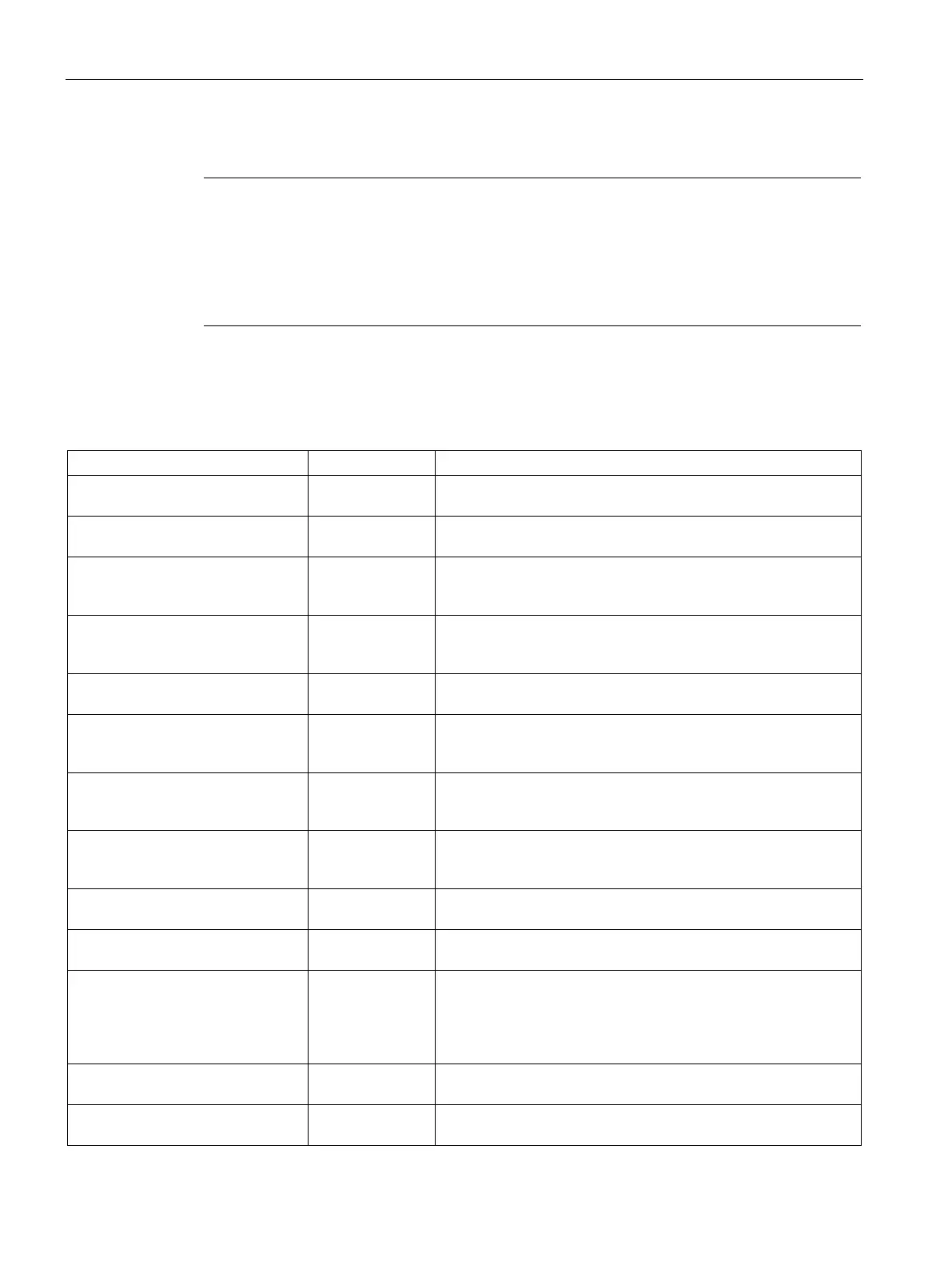

The following table lists a wide variety of materials and components that may or must not be

used in a cooling circuit.

Table 3- 6 Materials and components of a cooling circuit

Zinc Pipes, valves and

Use is not permitted.

Brass Pipes, valves and

Can be used in closed circuits with inhibitor.

Copper Pipes, valves and

fittings

Can be used only in closed circuits with inhibitors in which the

heat sink and copper component are separated (e.g. connection

Common steel (e.g. St37) Pipes Permissible in closed circuits and semi-open circuits with inhibi-

tors or Antifrogen N, check for oxide formation, inspection win-

Cast steel, cast iron Pipes, motors Closed circuit and use of strainers and flushback filters. Fe sepa-

rator for stainless heat sink.

High-alloy steel, Group 1 (V2A) Pipes, valves and

fittings

Can be used for drinking or tap water with a chloride content up

to < 250 ppm, suitable according to definition in Chapter "Cooling

water."

High-alloy steel, Group 2 (V4A) Pipes, valves and

fittings

Can be used for drinking or tap water with a chloride content up

to < 500 ppm, suitable according to definition in Chapter "Cooling

ABS (

crylnitrile

utadiene

tyrene) Pipes, valves and

fittings

Suitable according to definition in Chapter "Cooling water." Suit-

able for mixing with inhibitor and/or biocide as well as Antifrogen

Installation comprising different

materials (mixed installation)

Pipes, valves and

Use is not permitted.

PVC Pipes, valves,

Use is not permitted.

Hoses Reduce the use of hoses to a minimum (device connection).

Must not be used as the main pipe for the whole system. Rec-

ommendation: EPDM hoses with an electrical resistance > 10

9

Ω

(e.g. Semperflex FKD supplied by Semperit or DEMITTEL; from

PE/EPD, supplied by Telle).

Gaskets Pipes, valves and

Use of FPM (Viton), AFM34, EPDM is recommended.

Hose connections Transition

Hose - pipe

Secure with clips conforming to DIN EN 14420, available, e.g.

from Telle.

Loading...

Loading...