Maintenance

9.2 Inspection and maintenance

1LA5/6/7/9, 1LG4/6, 1MA6/7, 1MB..1/2/3/4/5 - SH 63 ... 355

Operating Instructions, 06/2018, A5E44455710A

115

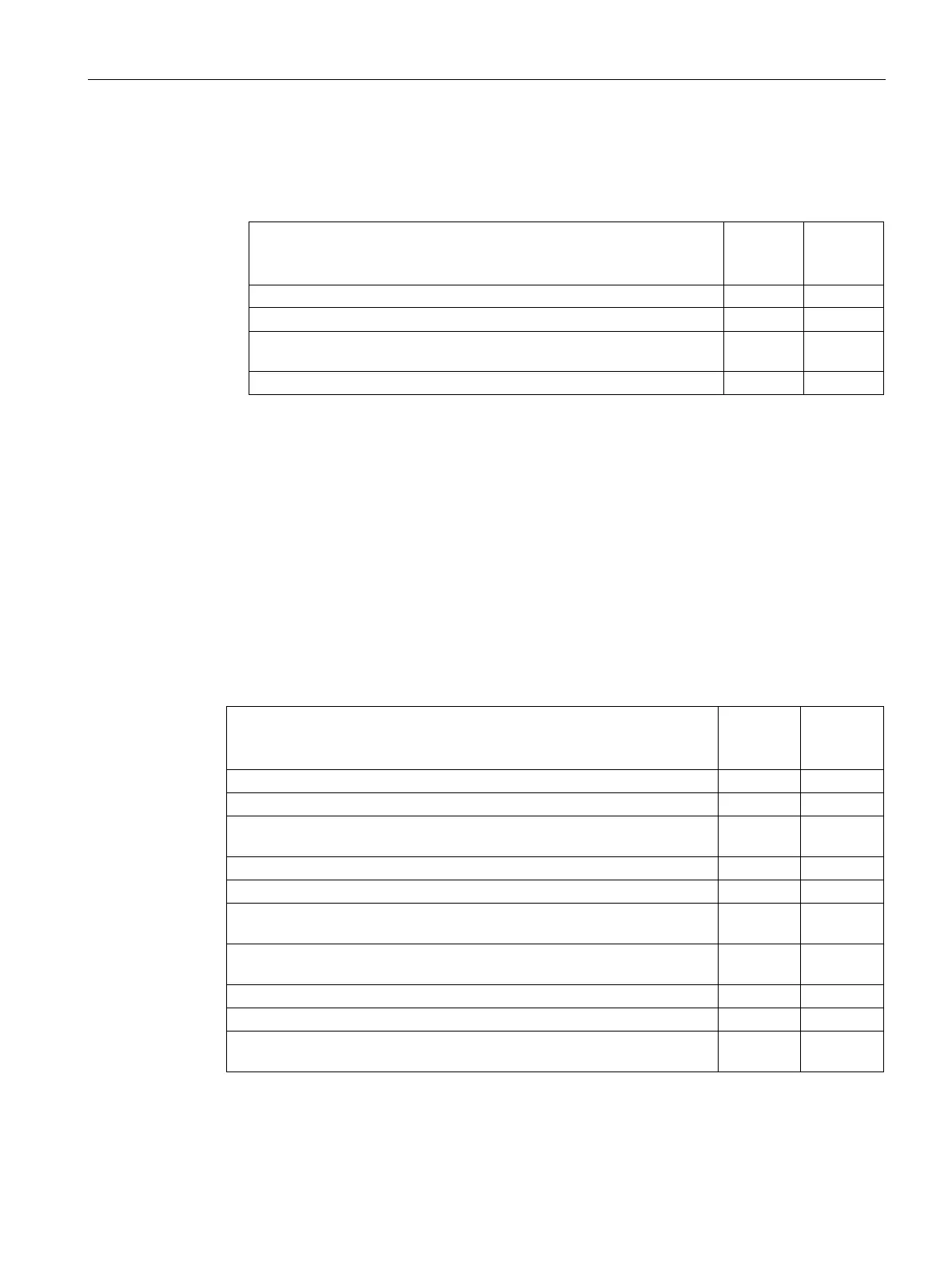

● Check after approx. 500 operating hours, but after not more than one year:

When the

motor is

running

The electrical parameters are maintained.

The permissible bearing temperatures are not exceeded.

The smooth running characteristics and machine running noise have not

The foundation has no cracks or indentations. (*)

(*) You can perform these checks while the motor is at standstill or, if required, while running.

● Further checks may be required if so specified in operating instructions of components or

in accordance with the plant-specific conditions.

● If you find any deviations during the inspection, you must rectify them immediately. They

may otherwise damage the motor.

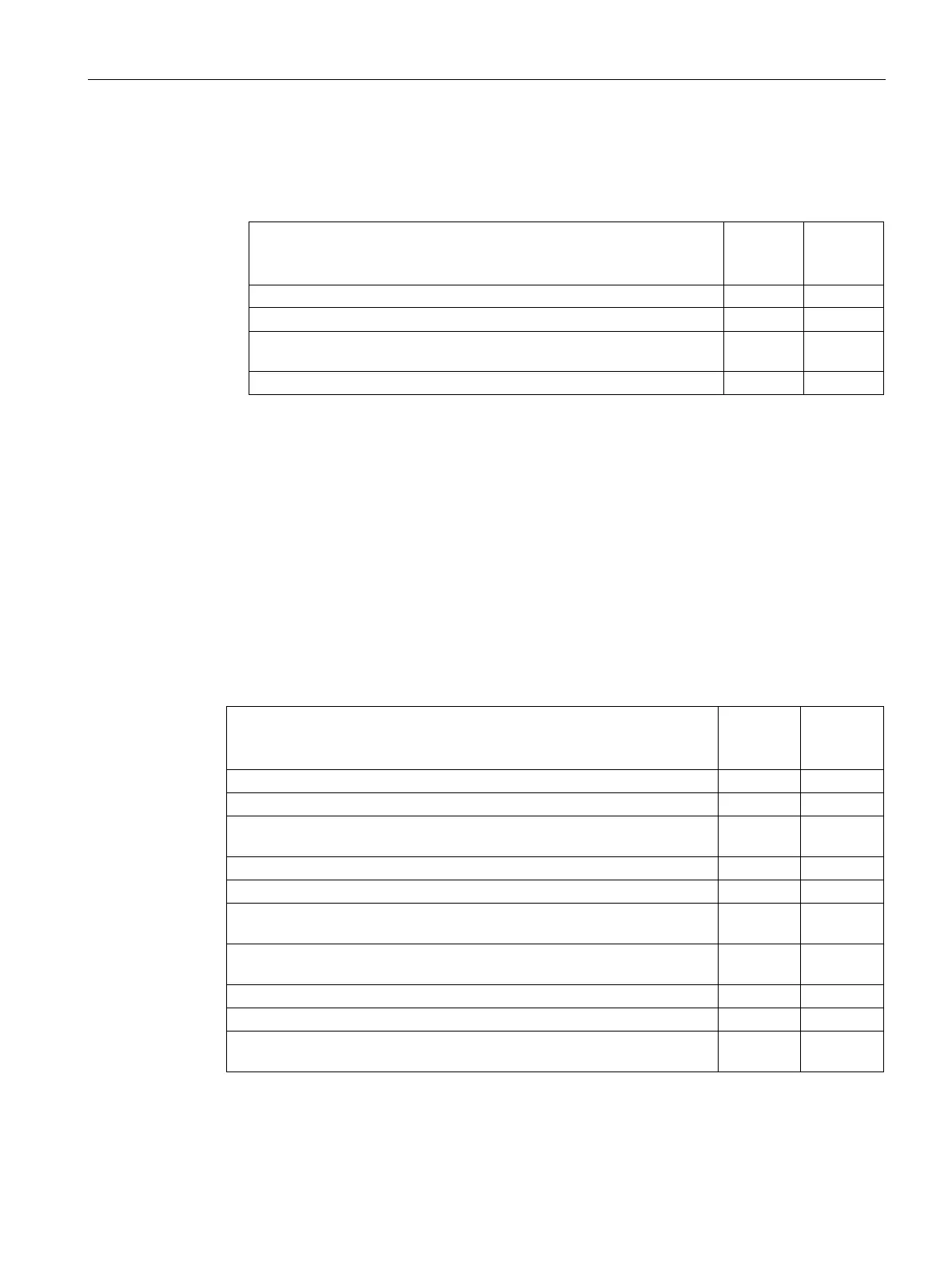

Check that the installation conditions are observed. We recommend that the following

checks are performed after approx. 16 000 operating hours or at the latest after two years:

Table 9- 1 Checks that have to be performed during the general inspection

When the

motor is

running

The electrical parameters are maintained

The permissible bearing temperatures are not exceeded

The smooth running characteristics and machine running noise have not

The motor foundation has no cracks and indentations (*)

The machine is aligned within the permissible tolerance ranges

All the fixing bolts/screws for the mechanical and electrical connections

have been securely tightened

All the potential connections, grounding connections and shield supports

are correctly seated and properly bonded

The winding insulation resistances are sufficiently high

Any bearing insulation is fitted as shown on the plates and labels

The CABLES and insulating parts and components are in good condition

and there is no evidence of discoloring

(*) You can perform these checks while the motor is at standstill or, if required, while running.

Loading...

Loading...