Maintenance

9.3 Corrective maintenance

1LA5/6/7/9, 1LG4/6, 1MA6/7, 1MB..1/2/3/4/5 - SH 63 ... 355

Operating Instructions, 06/2018, A5E44455710A

133

Observe the documentation for tightening torques of the cable entries and sealing plugs for

direct mounting at the machine as well as additional glands (e.g. adapters).

Terminal boxes, end shields, grounding conductors, sheet metal fan covers

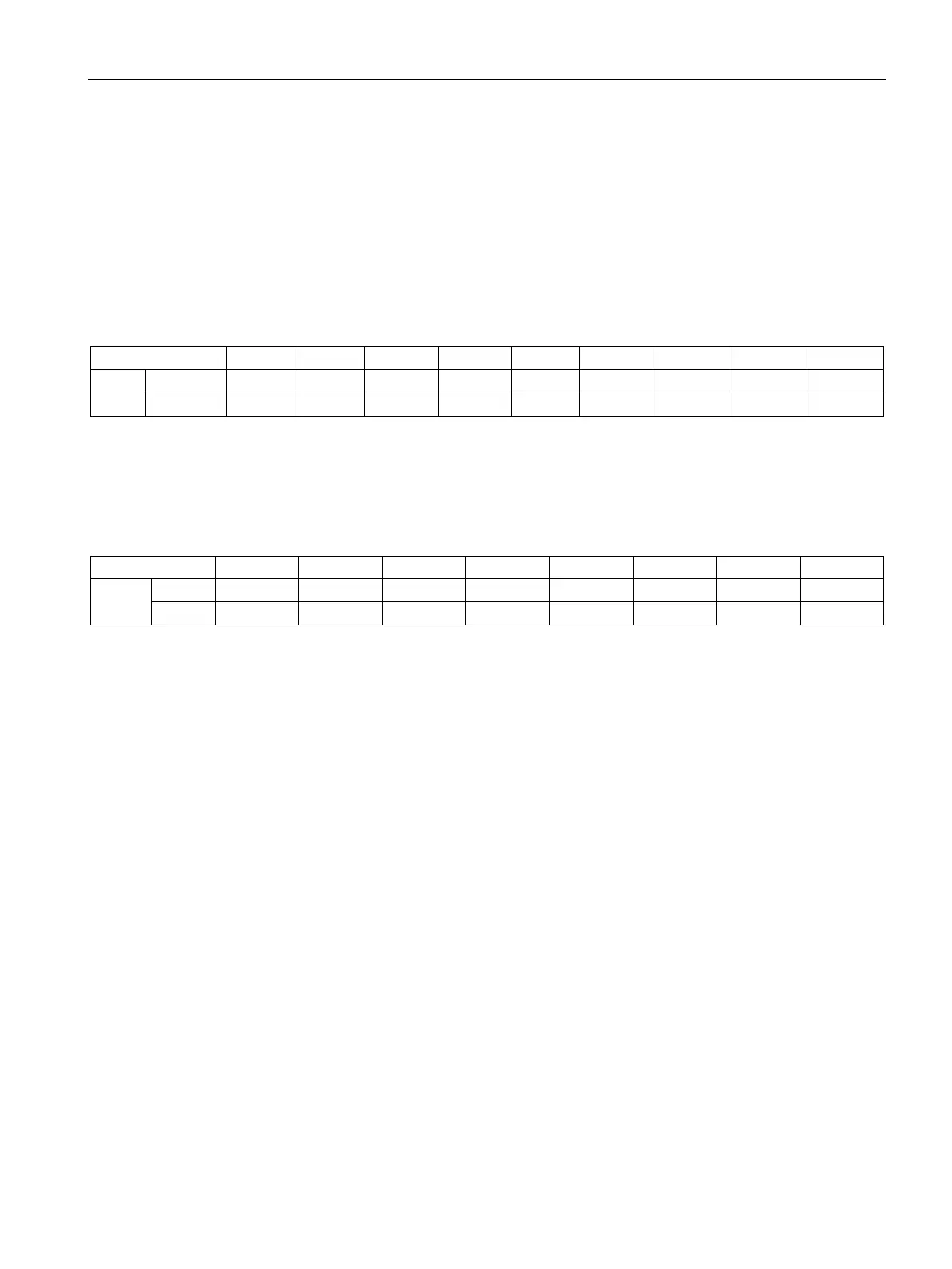

If no other tightening torques are specified, then the values in the following table apply.

Table 9- 4 Tightening torques for screws on the terminal box, end shields, screw-type grounding conductor connections

max 1.2 3 5 9 24 42 70 165 340

Terminal board and grounding

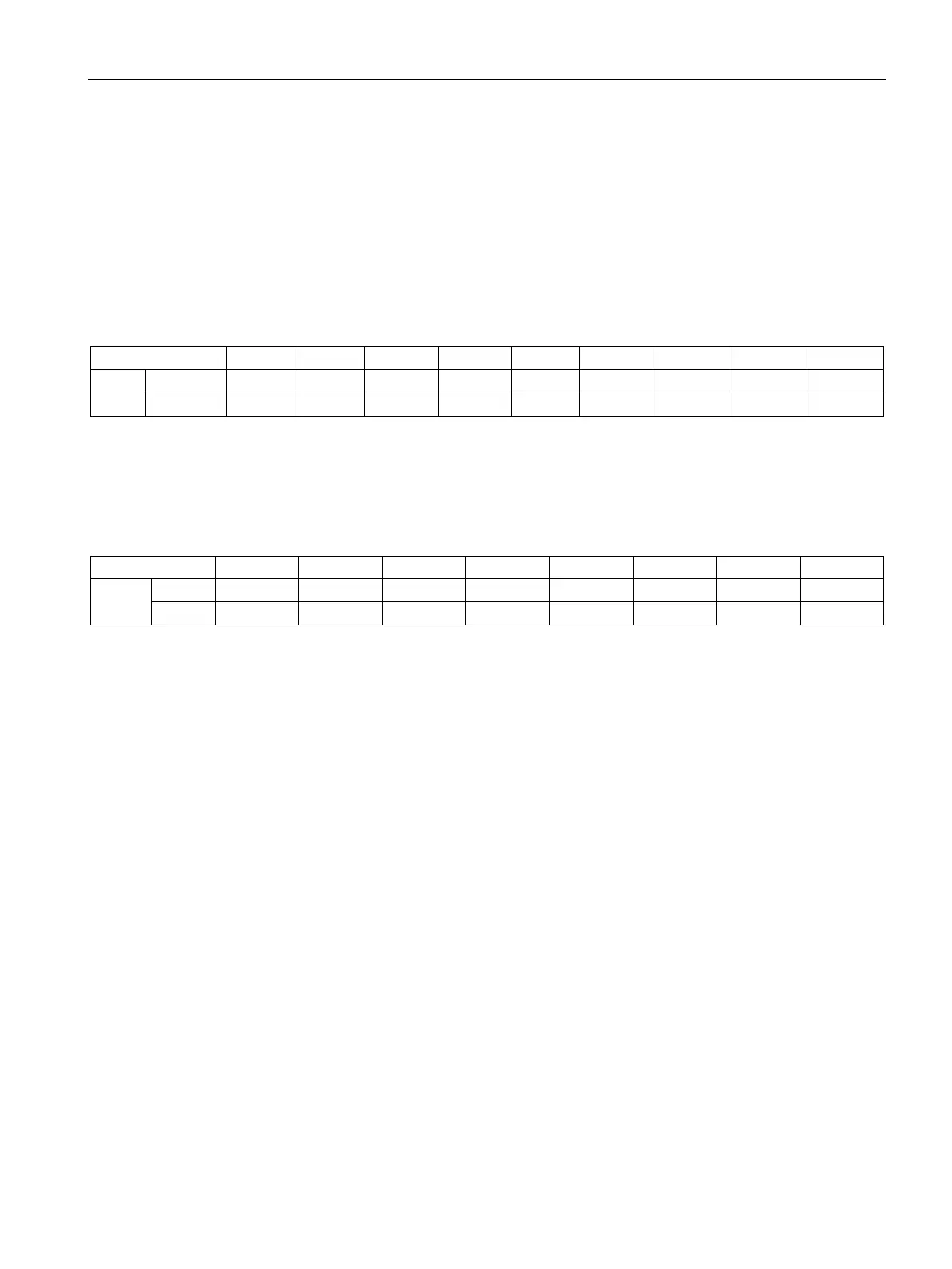

Table 9- 5 Tightening torques for electrical connections on the terminal board and grounding

Nuts or bolts that are mounted together with locking, resilient and/or force-distributing

elements (e.g., safety plates, spring-lock washers, etc.) must be refitted together with

identical, fully functional elements.

Locking and sealing elements must always be replaced!

● Replace any corroded screws.

● Take care not to damage the insulation of live parts.

● Document the position of any rating and supplementary plates that have been removed.

● Avoid damaging the centering edges.

Loading...

Loading...