04/2005 Installation

SINAMICS G110 Operating Instructions

6SL3298-0AA11-0BP0

27

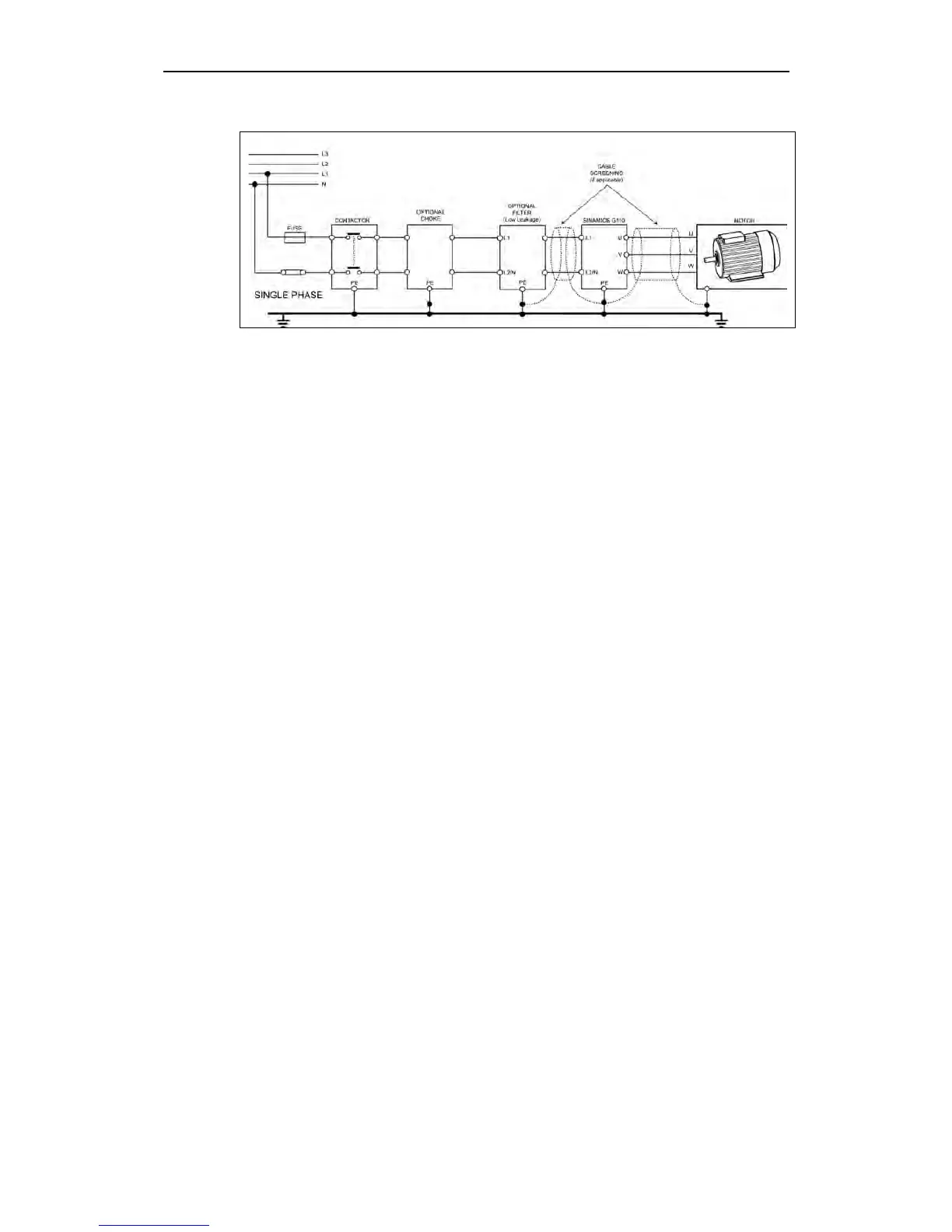

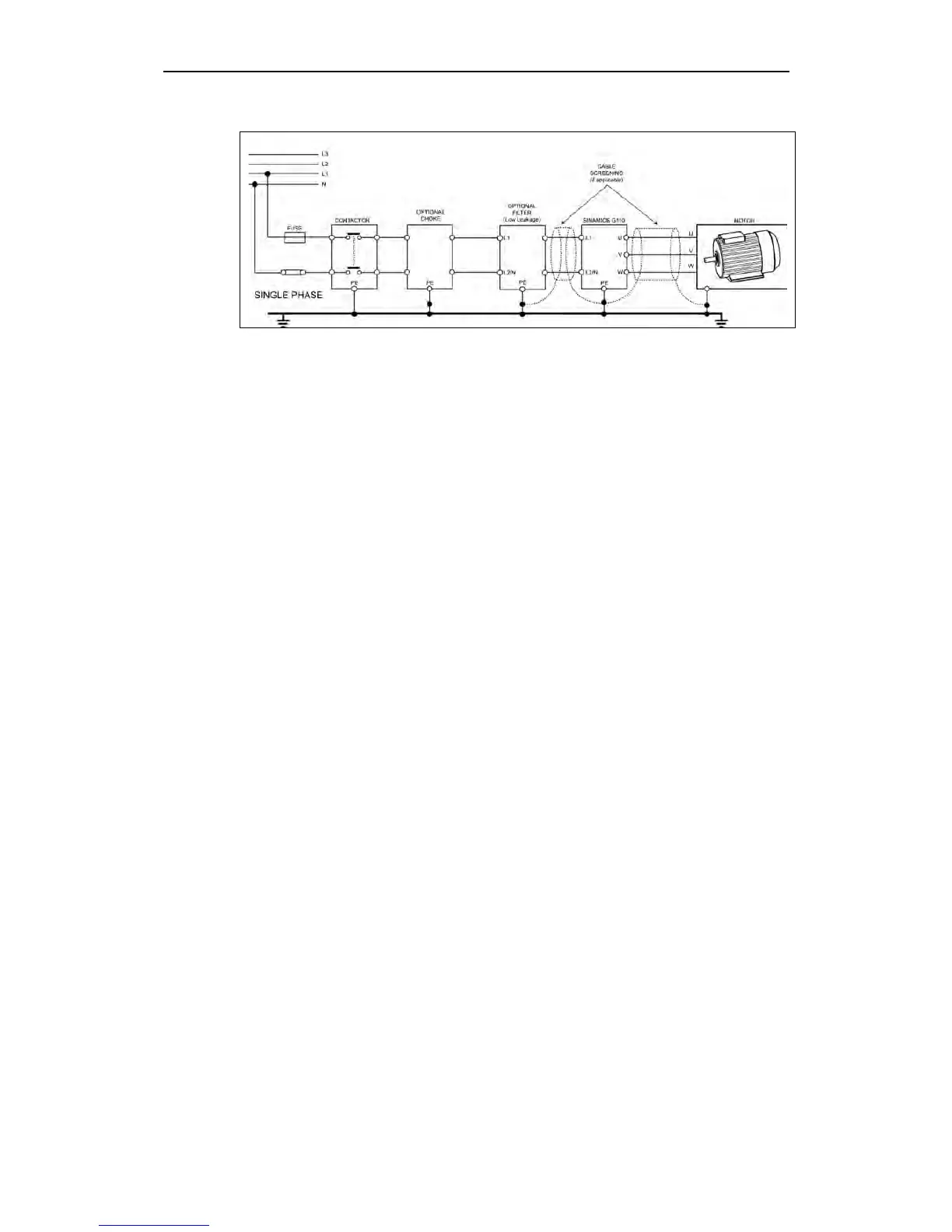

Figure 2-7 Motor and Power Connections

2.9.3 Avoiding Electro-Magnetic Interference (EMI)

The inverters are designed to operate in an industrial environment where a high

level of EMI can be expected. Usually, good installation practices will ensure safe

and trouble-free operation. If you encounter problems, follow the guidelines stated

below.

Action to Take

¾ Ensure that there is a good metal-to-metal connection between the inverter and

it’s (grounded) metal mounting surface.

¾ Ensure that all equipment in the cubicle is well grounded using short, thick

grounding cable connected to a common star point or busbar

¾ Make sure that any control equipment (such as a PLC) connected to the

inverter is connected to the same ground or star point as the inverter via a short

thick link.

¾ Connect the return ground from the motors controlled by the inverters directly to

the ground connection (PE) on the associated inverter

¾ Flat grounding conductors are preferred as they have lower impedance at

higher frequencies

¾ Terminate the ends of the cable neatly, ensuring that unscreened wires are as

short as possible

¾ Separate the control cables from the power cables as much as possible, using

separate trunking, cross them if necessary at 90º to each other.

¾ Whenever possible, use screened leads for the connections to the control

circuitry

¾ Ensure that the contactors in the cubicle are suppressed, either with R-C

suppressors for AC contactors or 'flywheel' diodes for DC contactors fitted to the

coils. Varistor suppressors are also effective.

¾ Use screened or armored cables for the motor connections and ground the

screen at both ends using the cable clamps

¾ For EMC compliant installation using the DIN Rail Mounting Kit, please refer to

Appendix B on page 80.

Loading...

Loading...