Functions

7.9 Technological functions

Inverter with CU240B-2 and CU240E-2 Control Units

Operating Instructions, 07/2010, FW 4.3.2, A5E02299792B AA

189

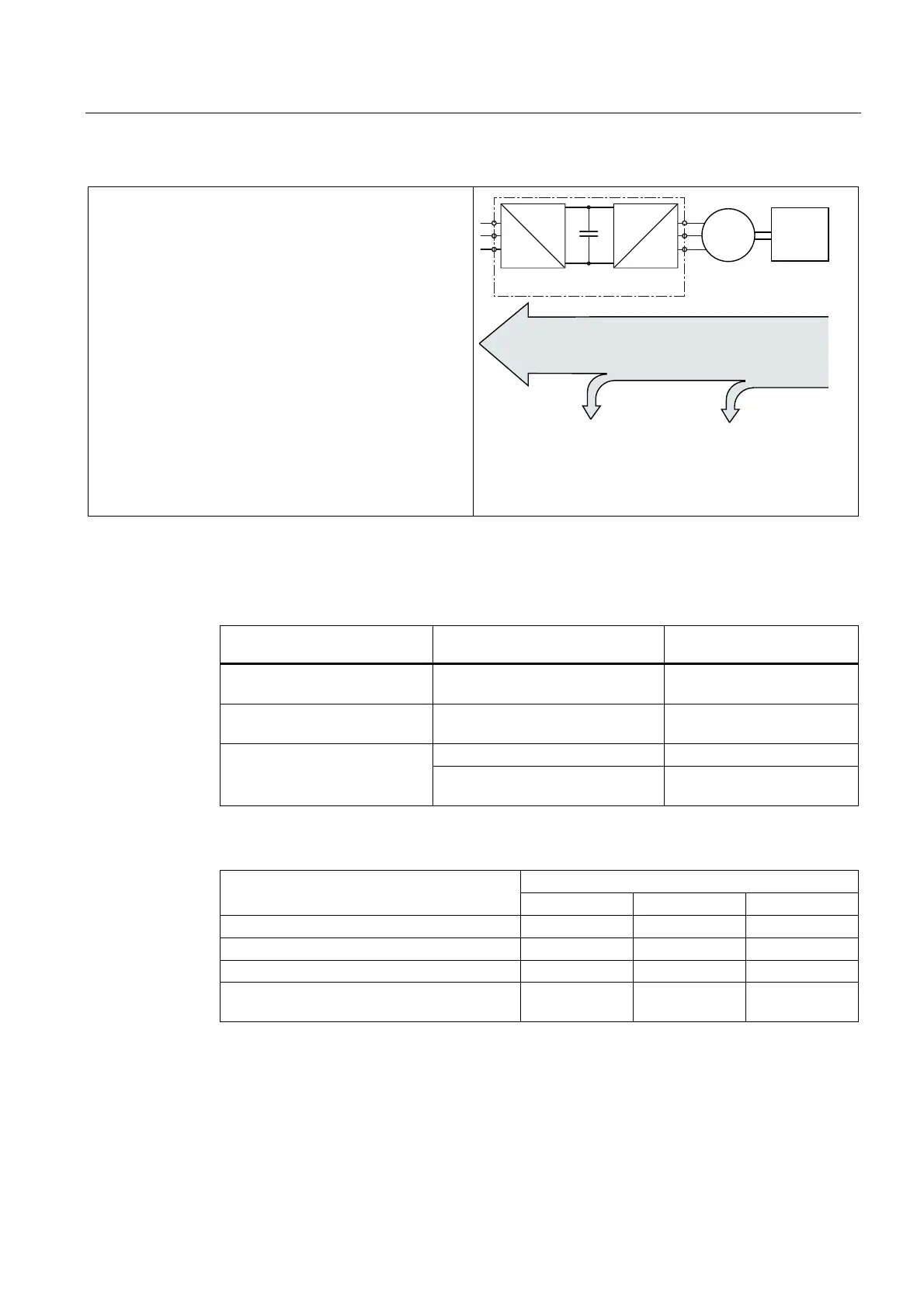

Braking with regenerative feedback into the line supply

Advantages:

Constant braking torque; the regenerative

power is not converted into heat, but is regenerated into

the line supply; can be used in all applications;

continuous regenerative operation is possible - e.g.

when lowering a crane load

Disadvantage:

Does not function when power fails

a

a

,QYHUWHU

5HJHQHUDWLYHIHHGEDFN

LQWRWKHOLQHVXSSO\

3RZHUORVVPRWRU

%UDNLQJSRZHU

/RDG

3RZHUORVV

LQYHUWHU

/RDG

0

The inverter feeds the regenerative power back into the

mains

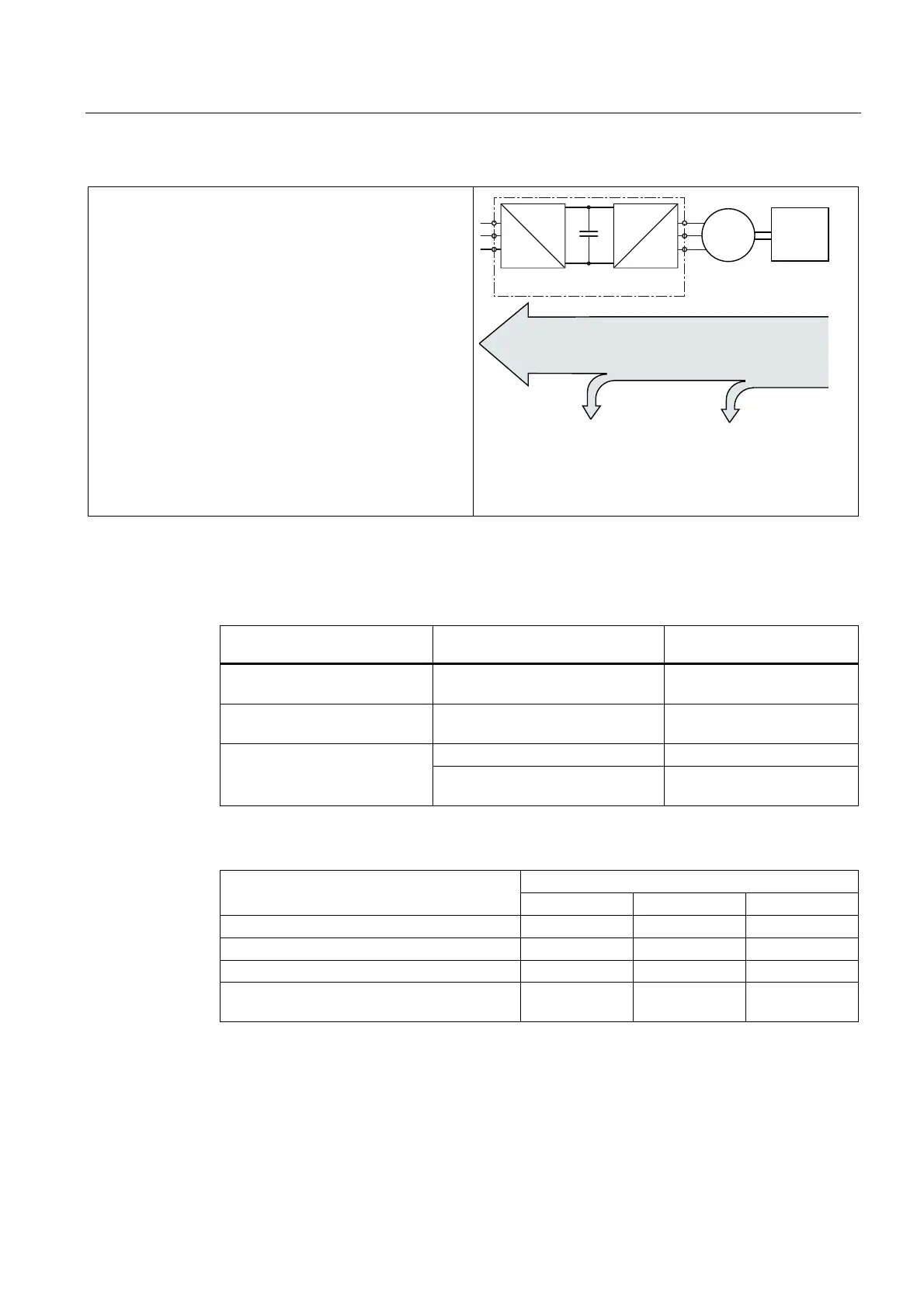

Braking method depending on the application

Table 7- 24 What braking method is suitable for what application?

Application examples Electrical braking methods Power Modules that can be

used

Pumps, fans, mixers,

compressors, extruders

Not required PM240, PM250, PM260

Grinding machines, conveyor

belts

DC braking, compound braking PM240

Dynamic braking PM240 Centrifuges, vertical conveyors,

hoisting gear, cranes, winders

Braking with regenerative feedback

into the line supply

PM250, PM260

Table 7- 25 What Power Module do you require for a specific braking method?

SINAMICS G120 Power Module

PM240 PM250 PM260

DC braking X X X

Compound braking X --- ---

Dynamic braking X --- ---

Braking with regenerative feedback into the

line supply

--- X X

Loading...

Loading...